Learn more about EMIS

Download FEMP's Energy Management Information Systems Technical Resources Report.

A strategic plan for Energy Management Information System (EMIS) deployment is imperative to establishing EMIS goals, scope, and capabilities. The Federal Energy Management Program (FEMP) recommends the following EMIS planning and procurement steps, including incorporating EMIS into energy savings performance contracts (ESPCs).

Steps for EMIS Planning

The EMIS planning process should be part of a site's overall energy management system (EnMS), which empowers energy-related staff and brings leadership into the continuous energy improvement process. The following planning steps support subsequent activities such as EMIS procurement, deployment, and operations.

Due to the number of stakeholders involved in each agency's EMIS deployment, it is critical to understand, document, and communicate the goals of an EMIS program. When setting goals, these questions are valuable to consider:

- How does EMIS support the agency’s overall energy management and facility management goals?

- In what ways will EMIS create direct and indirect value for the agency?

- How will the investment in EMIS be justified (i.e., what is the business case)?

- How will EMIS support agency compliance with federal laws and regulations?

- What key performance indicators will EMIS track to demonstrate success?

Implementation and operation of EMIS requires engagement at all organizational levels as well as expertise in building operations, metering technology, building controls, system integration, networking, network security, and the EMIS software selected.

EMIS teams are often made up of a combination of internal staff and external service providers. For example, it is common practice to hire a consulting engineering firm for ongoing monitoring, analysis, and measure identification and prioritization, allowing the internal operations and energy management team to take actions based on service provider recommendations. Agencies should assess internal capabilities to determine the need to hire new staff and the scope of work for external service providers.

Major roles and areas of responsibility that should be covered by an EMIS team are listed below.

- Agency national energy manager/EMIS program manager: An individual within the agency with overall jurisdiction and responsibility for EMIS program execution.

- Authorizing official: A senior agency official or executive within an agency with the authority to formally assume responsibility for operating an information system at an acceptable level of risk to agency operations and assets, individuals, other organizations, and the nation. The authorizing official is responsible for granting the authorization to operate an information system.

- Operational technology/information technology (IT) representatives: Most EMIS implementations involve extensive IT coordination to set up hardware or virtual servers, certify cybersecurity, pass data across the network, and, potentially, communicate with the cloud. The system should be designed and set up with involvement from the server, network, and firewall administrators. Involving them early in the process will help mitigate potential roadblocks as EMIS is implemented.

- System integrator and/or building automation systems technician: A system integrator or controls technician will be expected to understand the intricacies of the systems comprising the EMIS scope, including the system architecture and how each system can communicate with the EMIS. The system integrator will set up hardware and configure pathways and protocols for systems to communicate and transfer data.

- EMIS analyst: This team member is responsible for using the EMIS on a regular basis and ensuring it is configured properly for the organization. This typically includes the technical aspects of setting up the EMIS according to the EMIS plan and making sure the EMIS is actively used beyond initial setup, including hardware and software maintenance and upkeep.

- Energy manager and/or monitoring-based commissioning agent: This team member is responsible for leading and organizing the team through the EMIS operational process, ensuring that issues identified through the EMIS are tracked, validated, prioritized, implemented, and verified. This person also typically designs new analytics such as automated fault detection and diagnostics (AFDD) rules and key performance indicators.

- Facility managers and operations and maintenance staff: The team needs to include a member or members from the facility engineering and operations and maintenance staff. These team members are responsible for executing and managing the implementation of opportunities identified through the EMIS program.

- Program managers: This category includes staff who are responsible for the overall management of the EMIS program and who will coordinate within their areas and estimate budgetary needs.

- Project managers: The team includes staff who track installation and commissioning efforts, draft statements of work, coordinate with contracting offices, direct field personnel, and track budgets.

- Procurement specialists: Include staff who understand the agency's procurement protocols and who will coordinate procurement procedures such as requests for proposals.

- Contracting officers/representatives: These staff are authorized to perform contract administration functions and ensure contractors meet federal performance requirements.

- Program support personnel: Staff is needed to handle general logistics and supply chain management.

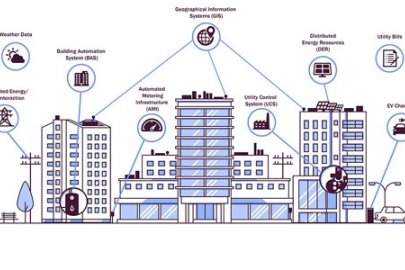

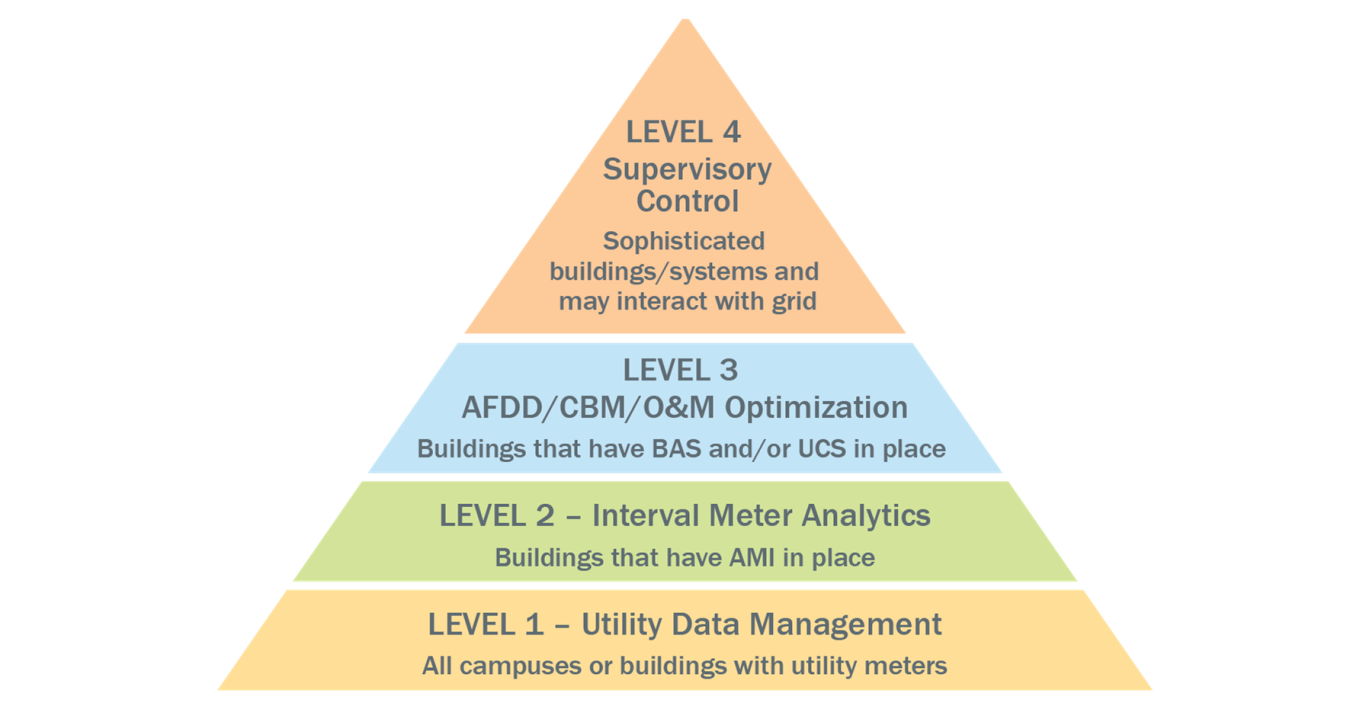

The next step in the planning process is to define the EMIS capabilities needed to meet the agency's goals. When defining capabilities, it is recommended to consider different sets of capabilities for different facilities in the portfolio. For example, small facilities without complex building systems will benefit from utility bill management and interval data analytics capabilities, but will see diminishing returns from adding more sophisticated system-level capabilities such as AFDD and supervisory control. In larger facilities with complex building systems, sophisticated EMIS capabilities may be vital to meeting goals. Each agency's EMIS plan will differ in how it applies EMIS capabilities across the portfolio. Once the capabilities are defined, the next step is to determine which building systems need to be integrated with the EMIS to fulfill them.

To illustrate this design approach, consider an agency with a broad mixture of different building sizes and sophistication. The first step would be to define the level of EMIS capabilities and scope to apply to all buildings. Then, for each subset of larger and more sophisticated buildings, define additional levels of capabilities and scope needed to meet agency goals. Eventually, for certain buildings the solution could include AFDD for utility control systems, supervisory control of building and utility controls, and providing applicable local grid services. The outcome for the agency may look similar to the figure below.

Each agency's EMIS plan will differ in how it will design an EMIS and apply its capabilities across the portfolio.

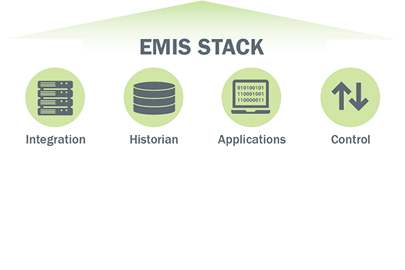

Image Credit: NLR, James Dice and Fred ZietzFinally, the EMIS design process should include considerations of the typical packages of capabilities available in the EMIS marketplace. For example, an EMIS vendor that focuses on Utility Bill Management capabilities will not typically provide more sophisticated capabilities, such as AFDD. Conversely, an EMIS vendor that focuses on AFDD will not typically provide standard Utility Bill Management capabilities; however, there are and will continue to be exceptions to these general trends as the marketplace evolves. Agencies can consider an EMIS stack that includes multiple vendors and products that meet the design intent rather than attempting to check all boxes with one vendor or product.

Once capabilities and scope are defined, confirm the initial EMIS concept by establishing feasibility. The feasibility of the EMIS plan starts with a survey of systems in the scope to provide a more detailed vetting and inform the planning of EMIS implementation. In this step, the goal is to determine what data exists, its resolution, and how it can be accessed and communicated with the EMIS. The understanding and investigation of existing data sources is key to subsequent steps. After the survey, the initial hardware and software architecture of the EMIS can be designed and used to create a budget and business case and obtain necessary approvals. When the budget is assembled it should include all costs inherent to an EMIS solution, including:

- EMIS scope upgrades: Costs associated with upgrades to enable desired EMIS functionality. Examples include energy metering hardware and communications, adding points to the building automation system, or retrofits

- Base EMIS cost: Costs associated with the software license and deployment labor

- Annual recurring costs: These include software license renewals or software-as-a-service fees and operations and maintenance labor

- Implementation costs: In-house and contracted labor, materials, and equipment associated with implementing opportunities identified through the EMIS operations process.

The business case can be completed by estimating the utility cost savings expected as a result of EMIS deployment and operations.

Finally, many building owners choose to conclude their feasibility assessment by performing a pilot project. For example, some decide to pilot one or two EMIS platforms (or a combination of platforms) on a small number of buildings over a 3–6-month period to ensure the EMIS platform meets the needs of the federal agency and is free of operational problems before deploying it at scale across the entire portfolio. During this piloting process it is also important to ensure that the EMIS platform delivers value and would result in a life-cycle cost-effective deployment when considering software-as-a-service costs, labor costs, and so on.

To maximize the effectiveness of the EMIS system, consider implementing a companion EnMS―an organizational process that codifies the energy goals and policies, empowers staff by leadership commitment, and executes on the EMIS outcomes to improve energy performance. The EnMS process includes proper staffing and training, developing energy improvement lists, and coordinating with energy and operations staff and management to implement operational and project-based improvements. An agency's EnMS should also comply with the ISO 50001 requirements of the Energy Act of 2020.

An EnMS establishes and manages the human side of energy performance improvement and utilizes EMIS data to enact further energy improvements. EnMS present an opportunity for management to create and empower an energy team and to prioritize energy improvements as a part of site operations. Creating operational processes requires consideration of how the team will:

- Review the EMIS for improvement opportunities

- Take action to implement improvements

- Coordinate or obtain needed authorizations

- Verify that the improvements were successful

- Communicate results to key stakeholders

- Manage and operate the EMIS while synergizing human and data flows to optimize energy performance.

The U.S. Department of Energy's no-cost 50001 Ready Program offers support and recognition for agencies implementing an EnMS among other ISO 50001-based energy management systems.

The final step in EMIS planning brings together the detailed information needed for procurement and deployment of the EMIS. Depending on the scope of implementation, the following documentation may be needed for deployment:

- EMIS program goals: Goals of the project, recommended capabilities, EMIS data sources/scope, and so on

- Roles and responsibilities: Roles assigned to internal and external team members

- Facility documentation: Current facility requirements, utility account and meter information, meter and equipment lists, drawings, system architectures, sequences of operations, recent energy audits or commissioning reports

- EMIS architecture: Network diagram, hardware and software required, IT integration method, EMIS scope integration method

- EMIS scope: Equipment list for each system, points list to and from each system

- EMIS capabilities: Analysis methods to be performed, user interface requirements, analytics (such as FDD rules and KPIs) requirements, modeling requirements, customizations

- Data management standards: Point naming standard, data modeling standard, and data ownership policy.

Steps for EMIS Procurement

Once an agency has established an EMIS plan, they are ready to procure software and services. Federal agency EMIS teams should be aware of several key considerations when creating a request for information (RFI) or request for proposals (RFP) to purchase EMIS technology and services.

The breadth of the EMIS software market can be overwhelming for EMIS teams. Before releasing an RFP, consider defining requirements carefully such that it narrows the field of qualified respondents using the EMIS planning process outlined above.

Due to the breadth of the EMIS software market, software vendors vary in how well they fulfill individual capabilities. Depending on the agency's EMIS plan, it may be most beneficial to select multiple vendors to ensure the entire spectrum of capabilities desired are provided. Regardless of whether one or multiple vendors are selected, the resulting EMIS needs to seamlessly accommodate all types of data—from monthly data down to 1-minute intervals, if needed.

A point of confusion for prospective EMIS buyers is the scope of what vendors have included in their proposals. This makes it difficult to compare proposals in an apples-to-apples manner. Some vendors provide only software, while others provide only services while reselling software provided by others. Others still provide software and services as a bundled package. Software vendors may provide their product under a software-as-a-service agreement or other type of agreement.

Each vendor's proposal should explain the pricing structure for all software, hardware, integration, data commissioning, other services, and costs required for the project. The scope and pricing should be broken out in the following categories at a minimum:

- Hardware

- Software licenses

- Annual software license maintenance fees

- Software and hardware set-up labor

- Annual maintenance labor.

When defining the scope, consider creating a dedicated scope for third-party service providers. If this scope is a significant portion of the EMIS project, consider selecting a software vendor with an active network of third-party service partners to minimize future dependence on one service vendor.

One emerging best practice is installing a separate driver and historian layer allowing the trial and testing of multiple EMIS applications without needing to restart the integration from scratch. If the agency operates a large campus or portfolio, it could be beneficial in the long term to trial two or three EMIS applications to get a direct apples-to-apples comparison. Once the vendor or vendors are selected, the EMIS can be rolled out to the rest of the campus/portfolio at lower risk.

The RFP needs to specify the agency's operational technology and IT requirements, including storage, backup, hosting (local and/or cloud), security, permissions, and access control.

Learn more about cybersecurity standards in the EMIS Cybersecurity Best Practices fact sheet.

Need the RFI/RFP template? Download EMIS Specification and Procurement Support Materials to create a customized draft RFP to match your agency’s EMIS plan.

Download the Best Practices for Enhancing Performance Contracts with Monitoring-Based Commissioning fact sheet.

Financing EMIS with Energy Savings Performance Contracts

Integrating EMIS into an ESPC offers benefits to both agencies and energy services companies (ESCOs), and serves as an enabling mechanism to help federal agencies meet federal laws and mandates.

ESPC Benefits to Federal Agencies

There are four primary drivers for federal agencies to finance EMIS through performance contracts.

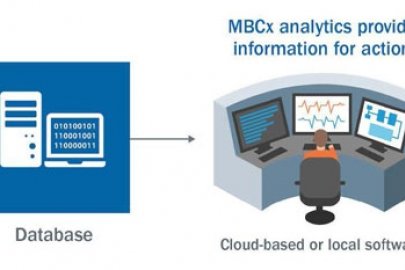

Depending on the level of EMIS deployed, the platform can provide increased savings from monitoring-based commissioning and fault detection and diagnostics. In addition, more advanced EMIS platforms include advanced system optimization via supervisory control―a new category of energy conservation measure that can be included in the ESPC. For example, advanced system optimization algorithms typically optimize variable systems in real time while more simple supervisory control algorithms will poll all space temperature set points over a large number of buildings and ensure compliance with agency guidelines.

Use of EMIS allows for more accurate baselining through integration of building automation system trend and advanced metering infrastructure data, enabling greater rigor in measurement and verification (M&V). In addition, automated M&V calculations can decrease M&V labor costs for the ESCO and virtual and low-cost submetering can be integrated into the project to increase M&V accuracy and fidelity.

If the platform includes automated fault detection and diagnostics, the EMIS will constantly monitor system performance and can identify new operations and maintenance items in near-real time, improving the process for identifying and fixing deficiencies. These fault detection and diagnostics rules can be deployed for all new energy conservation measures in the contract and used to ensure that ESCO-installed equipment continues to operate correctly over the life of the contract. EMIS platforms unite data from independent and siloed systems to enable new visualizations of data that can be used by onsite staff to identify operational problems―for example, electrical load profile analysis can show that lights are being left on after hours.

EMIS platforms that provide control over multiple end uses within a building can also enable grid-interactive efficient building technologies and more advanced load flexibility as an energy conservation measure within the contract. As more Internet of Things (IoT)-connected devices come online, the EMIS can serve as the central platform that connects to each IoT gateway and uses the IoT data for advanced analytics and control.

ESPC Benefits to ESCOs

Financing federal EMIS with ESPCs offers a number of benefits to ESCOs.

EMIS implementation can lead to the development and maintenance of positive long-term relationships with federal clients. EMIS offer more robust ongoing performance assurance, which leads to better building performance and increased agency trust in the ESCO. Often, an ESCO provides a full-time staff member as operator of the EMIS, allowing the ESCO to become part of the operations and maintenance team. This ongoing relationship also allows the ESCO to provide more improvements throughout the contract term, or later under a separate operations and maintenance or software-as-a-service contract.

ESCOs that integrate EMIS within their service offering allow them to be more innovative than their competitors. This deeper investment also ensures additional savings are realized over the life of the contract, through more innovative technology offerings like grid-interactive efficient buildings, the use of IoT devices, and improved M&V practices that allow for more transparency versus other ESCOs.

The process of gathering building automation system trend or logger data, weather data, and utility consumption data can be significantly improved upon using an EMIS, giving the ESCO team web-based access to data with minimal effort. Further, the data gathering infrastructure can be left in place and reused throughout the guarantee period. Implementing EMIS early in the process can also reduce travel costs by allowing remote auditing and monitoring.

If the EMIS suite includes automated fault detection and diagnostics, the EMIS platform will improve the commissioning process through features such as automation of data analysis and control system verification. In this case, the ESCO will test 100% of the equipment, which would otherwise only be sampled. If retro-commissioning is an energy conservation measure within the ESPC, the EMIS platform will automate many of the retro-commissioning tasks, enable ongoing monitoring-based commissioning, and reduce travel costs associated with commissioning.

EMIS also allows an ESCO to automate the M&V process, which reduces labor costs. Further, predictive maintenance add-ons to the EMIS can be used to predict equipment failure and/or extend equipment life, helping to avoid equipment failures before the loan is repaid. Remote monitoring reduces travel costs and allows savings to be measured in real time, rather than waiting months for utility bills.