Building America Team: Southface Energy Institute

Partners: Emory University, Senseware, Underwriters Laboratory, Venmar Ventilation ULC, and Beazer Homes

Southface Energy Institute and partners are developing and validating an assessment protocol incorporating low-cost (IAQ) sensors for homes by monitoring four new-construction homes in Charleston, South Carolina, with “smart” energy recovery ventilators (ERV). The team will also assess occupant comfort between continuous ventilation and time-varying ventilation modes toggling biweekly. The performance-based approach and smart ERV solution will achieve annual HVAC energy cost savings of approximately $100 compared to central fan integrated supply system, as well as a 50% reduction in ventilation-related latent loads compared to supply or exhaust ventilation strategies. This technology will contribute to overcoming homebuilder reluctance around airtightness and ventilation strategies, enabling energy savings from tight construction in hot and humid climates while reducing IAQ risks and improving comfort.

An assessment protocol monitoring IAQ and occupant comfort at new-construction homes with “smart” energy recovery ventilators will enable greater HVAC energy savings from tight construction in hot and humid climates while reducing IAQ risks and improving comfort.

Progress

- Collaboration with Senseware to select low-cost IAQ sensors for sensor package.

- Senseware IAQ package now commercially available.

- Collaborated with Brone/Venmar to modify smart ERV to remotely toggle between “smart”/“continuous” modes using Senseware platform.

- Collaborated with NREL to modify BEopt program to include CFIS modeling.

- CFIS modeling capability now publicly available.

- Completed baseline performance of Senseware sensor package prior to deployment.

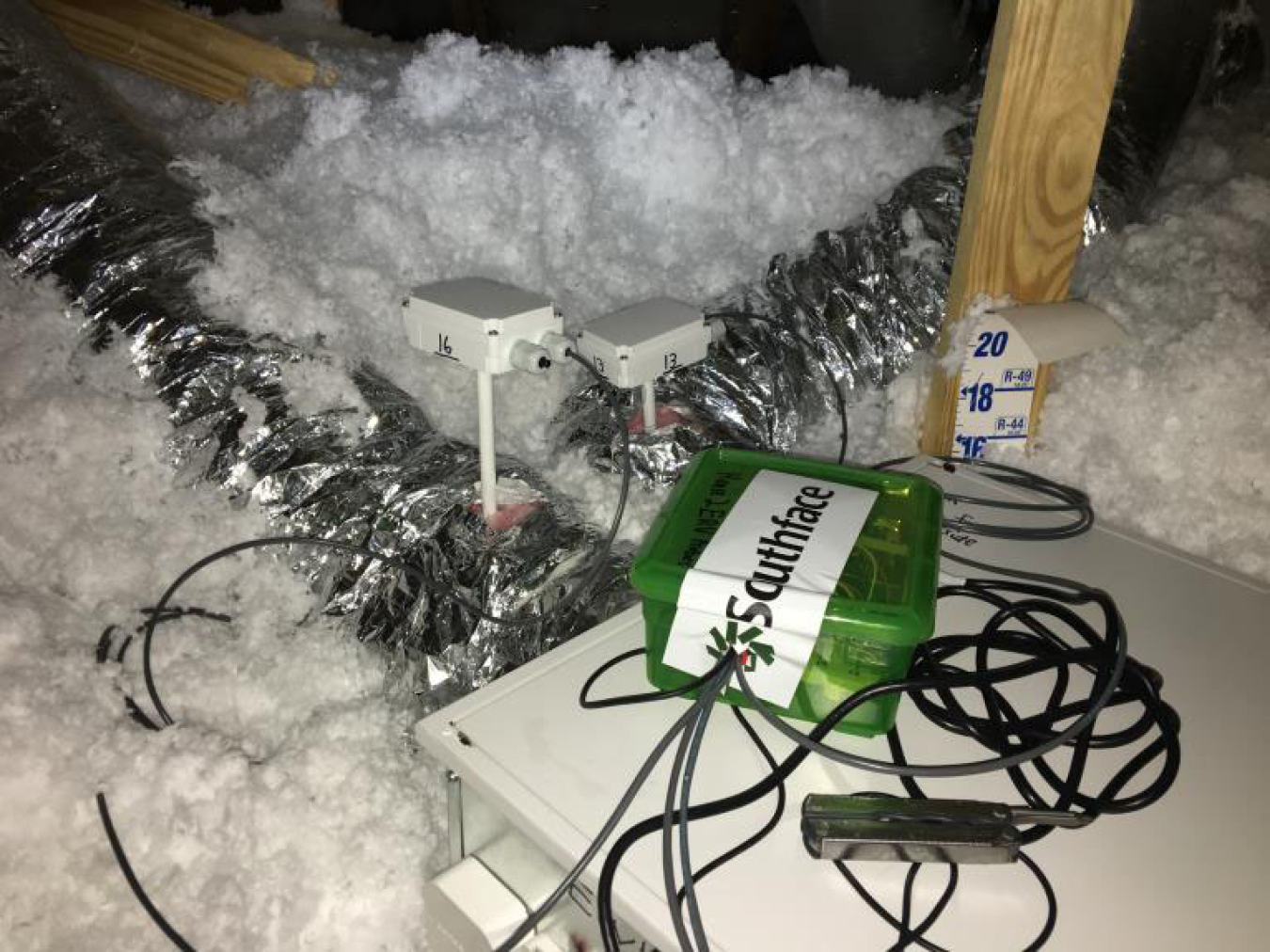

- All four Charleston homes have been performance tested, have sensors and monitors installed, and the ERVs are online.

- Monitoring and analyzing performance data, toggling biweekly, and quarterly check-in and filter change.

Data Observations

- Likely seeing volatilization of dust and/or semivolatile organic gases that have deposited on the heat exchanger.

- Volatized chemicals recondense into particles in the air as it cools in the home; team’s PM2.5 sensors are able to see this.

- Expectation is that this should wane after more cycles.

- Furnace PM2.5 generation appears to have steadily declined and stopped in all houses after about a month.