Lead Performer: Oak Ridge National Laboratory – Oak Ridge, TN Partner: Samsung Electronics America Inc. – Ridgefield Park, NJ

May 3, 2019

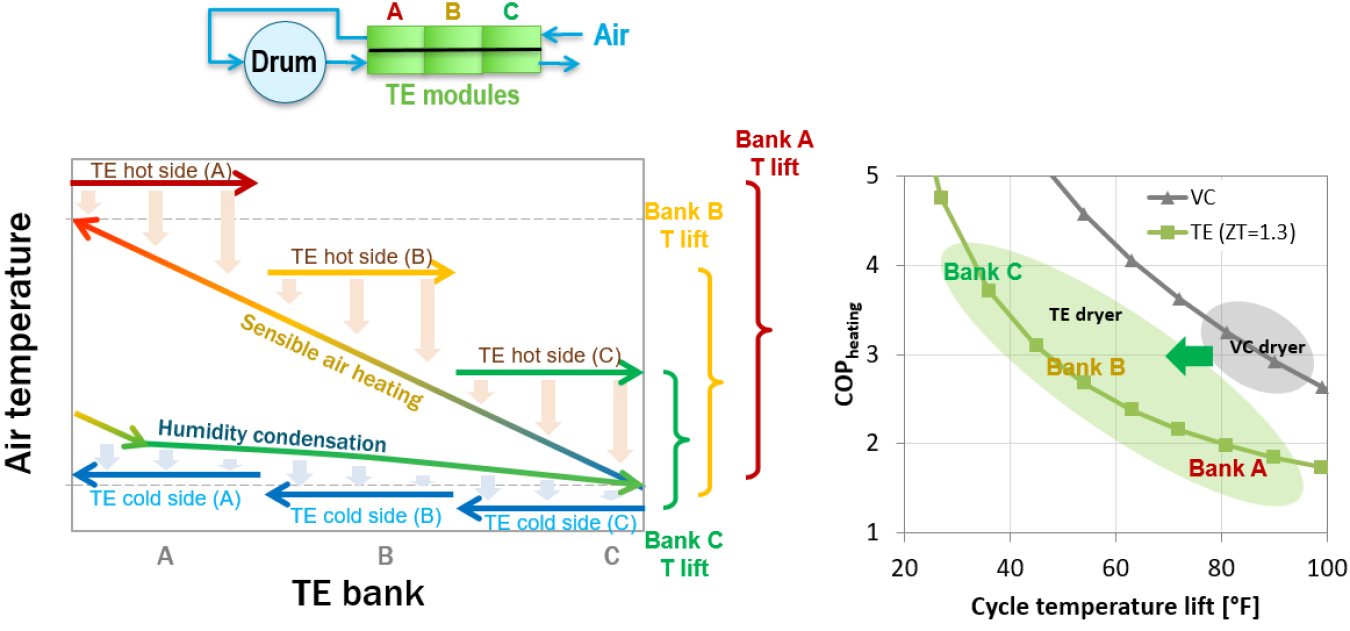

In the TE dryer concept developed in this work, the traditionally inferior efficiency of thermoelectric heat pumps (compared with vapor compression heat pumps) is overcome by the inherent scalability and modularity of TEs. Image credit: ORNL

Lead Performer: Oak Ridge National Laboratory – Oak Ridge, TN

Partner: Samsung Electronics America Inc. – Ridgefield Park, NJ

DOE Total Funding: $1,050,000

Funding Type: CRADA

Project Objective

Oak Ridge National Laboratory will research and develop a thermoelectric clothes dryer concept. The team will start the project using thermodynamic system modeling. The team will develop a prototype, evaluate, and compare it to a baseline vapor compression heat pump clothes dryer.

Fabrication of a thermoelectric prototype with a liquid-pumped-loop thermoelectric heat pump will also be followed by an accelerated experimental study of the long-term effects of power quality and power cycling on thermoelectric module performance.

This project’s thermoelectric-based approach to clothes dryer is projected to have a lower first cost than vapor compression dryers by replacing refrigerant lines, compressor and an expansion device with low-cost thermoelectric modules, a water-pumped loop and low-cost power supplies.

Project Impact

The U.S. clothes dryer market is large, with over 80% of U.S. households possessing one. This project has the potential to save 40% in primary energy (254 TBtu/year) compared to baseline efficiency dryers. Faster dryer times are also possible compared to vapor compression dryers. Additionally, solid-state thermoelectric heat pump technology does not use any refrigerants.

Contacts

DOE Technology Manager: Antonio Bouza

Lead Performer: Kyle Gluesenkamp, Oak Ridge National Laboratory

Related Publications

- Gluesenkamp, Kyle R., Philip Boudreaux, Viral Patel, Dakota Goodman, Bo Shen (2019). “An efficient correlation for heat and mass transfer effectiveness in tumble-type clothes dryer drums,” Energy, v. 172, 1225-1242. (April 2019). https://doi.org/10.1016/j.energy.2019.01.146

- Patel, Viral; Kyle R. Gluesenkamp, Dakota Goodman, Anthony Gehl (2018). “Experimental evaluation and thermodynamic system modeling of thermoelectric heat pump clothes dryer,” Applied Energy, v. 217, 221-232. (May 2018) https://doi.org/10.1016/j.apenergy.2018.02.055

- Kyle R. Gluesenkamp, (2018). “Thermoelectric clothes dryer,” DOE Building Technologies Office 6th Annual Peer Review, April 30–May 3, 2018, Arlington, Virginia. available at https://www.energy.gov/sites/prod/files/2018/06/f52/32226o_Gluesenkamp_050218-1100.pdf

- Patel, Viral K. Hsin Wang, Kyle R. Gluesenkamp, Anthony Gehl, Geoffrey Ormston, Emily Kirkman (2018). “Long-term effects of power quality and power cycling on thermoelectric module performance,” Proceedings of the ASME 2018 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems (InterPACK), San Francisco, CA, August 28-30, 2018.

A full scale prototype thermoelectric dryer has been fabricated and evaluated at ORNL. Photo credit: ORNL.