Lead Performer: Oak Ridge National Laboratory – Oak Ridge, TN; partner: WinBuild Inc. – Fairfax, VA

June 23, 2020

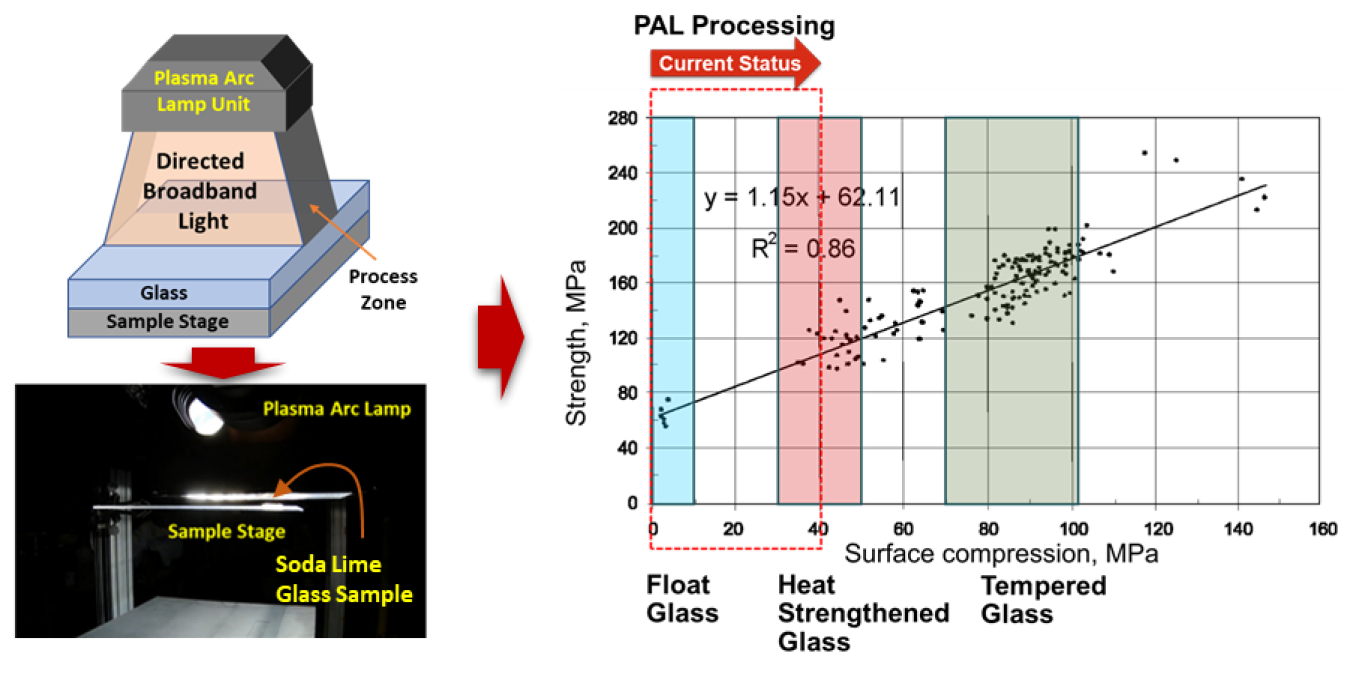

Ongoing directed Plasma Arc Lamp (PAL) processing investigation establishes glass compressive stress tuning at low thermal budgets, meeting the requirements of float glass and heat strengthened glass applications.

Lead Performer: Oak Ridge National Laboratory – Oak Ridge, TN

Partner: WinBuild Inc. – Fairfax, VA

DOE Total Funding: $1,500,000

Project Term: October 1, 2018 – September 30, 2021

Funding Type: Lab Award

Project Objective

This project will research a scalable, low-cost processing strategy for glass strengthening and sealing to impact the thermal performance of insulating glass units. A combination of large area photonic processing, additive manufacturing, and laser encapsulation techniques is proposed to realize a vacuum glazing technology meeting the cost, performance, reliability, and throughput demands. The specific aims of the proposed research and development (R&D) to realize an integrated vacuum insulated glazing (VIG) technology include scalable pulse thermal processing for in-line glass strengthening, laser-assisted hermetic sealing, and additive manufacturing of low thermal conductivity pillar spacers, secondary edge seal, and vacuum valve. The integration of materials, component design, and manufacturing innovation attempts to address the technology adoption considerations of an insulated glass manufacturer (IGU) or an end window manufacturer.

Project Impact

Windows only take up between 5-10% of a home’s total surface area that is exposed to outside temperatures but account for as much as 30% of the heat lost in a home. Against the background of continuously rising energy costs, windows are identified as critical weak spots; therefore, developments in the field of vacuum insulation glazing are of great importance. Scout estimates the heating energy use associated with window conduction in residential and commercial building as 3.9 Quads in AIA climate zones 1-3. The low-cost vacuum glazing unit being developed in this project would contribute significantly toward reducing this energy consumption; even with 15% market adoption, the savings would be more than 585 TBtu.

Contacts

DOE Technology Manager: Marc LaFrance

Lead Performer: Pooran Joshi, Oak Ridge National Laboratory

Related Publications

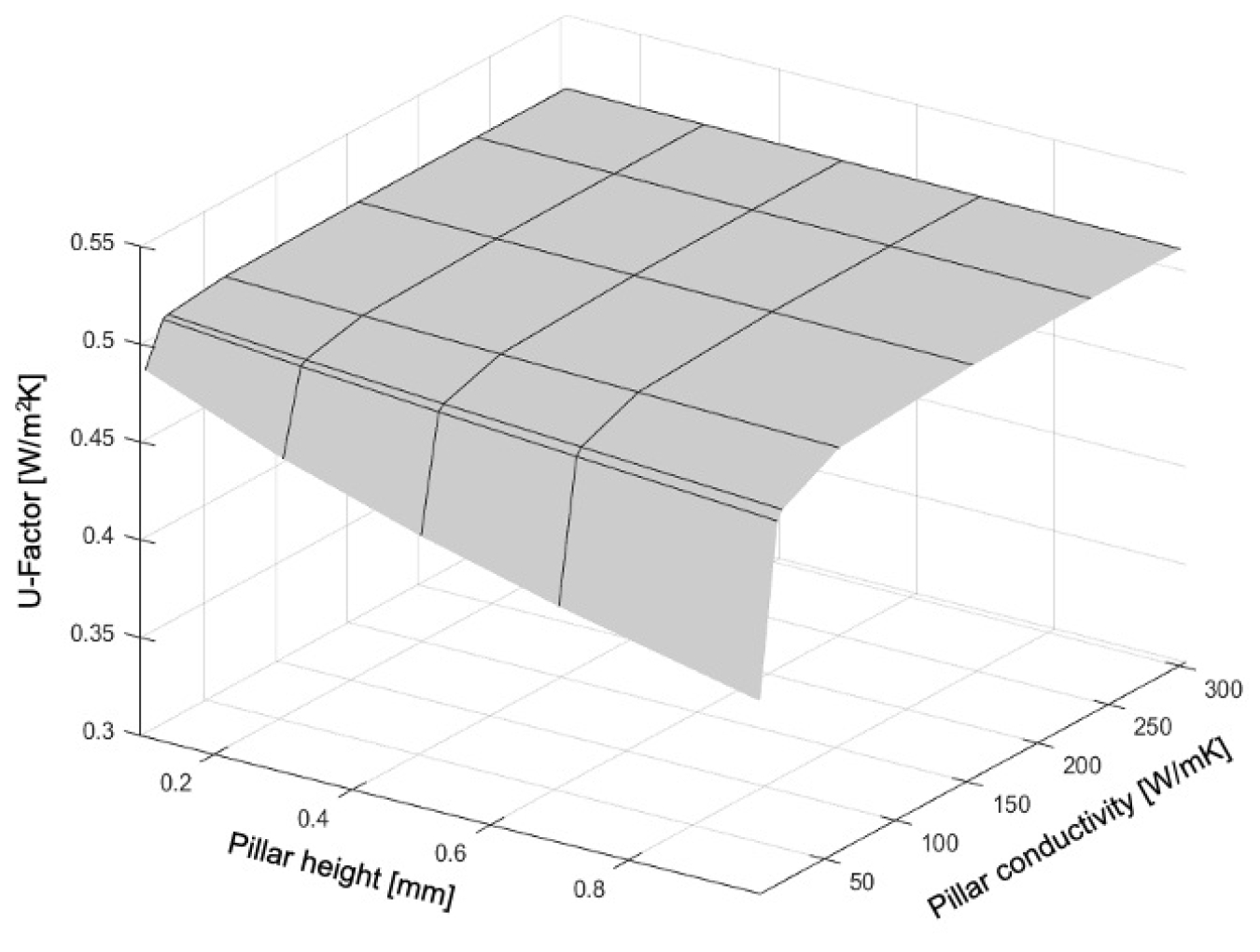

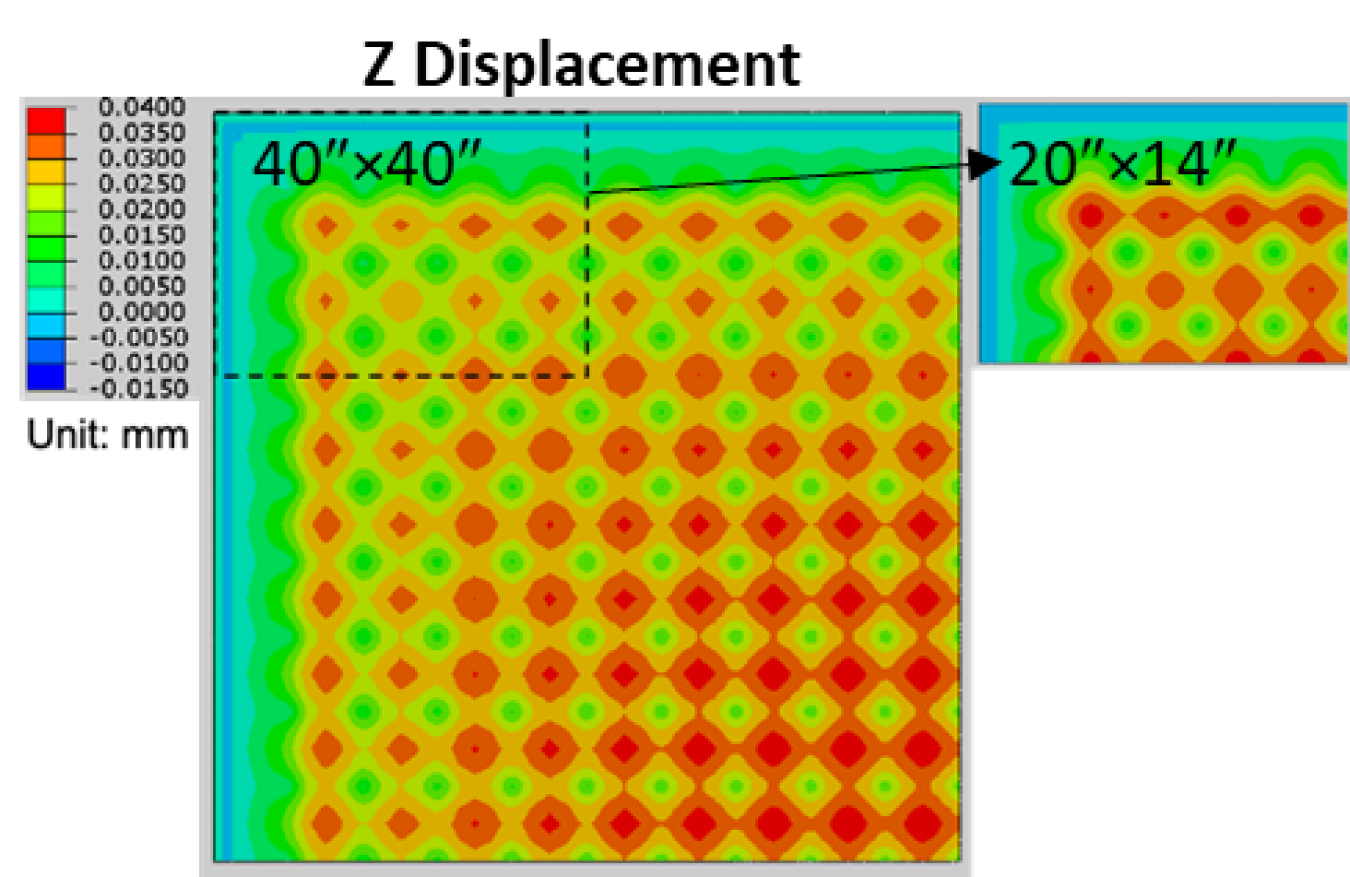

Modeling of VIG unit leads to an understanding of the (a) impact of pillar height and thermal conductivity on U-factor and (b) stress profile due to non-uniform displacement of glass panes.