Lead Performer: Oak Ridge National Laboratory (ORNL) – Oak Ridge, TN Partner: University of Northern Iowa

May 13, 2019Lead Performer: Oak Ridge National Laboratory (ORNL) – Oak Ridge, TN

Partner: University of Northern Iowa

DOE Total Funding: $450,000

Project Term: October 1, 2018 – September 30, 2020

Funding Type: Direct Funded

Project Objective

Certain rotary compressor technologies in refrigeration and air-conditioning systems require oil to provide lubrication, cooling, and leak tightness between compression stages. However, managing the oil can be an issue and fouling in heat exchangers can lead to performance losses of 10-15% over time. To address these losses, the project team will develop an oil-less compressor that would help to reduce problems with fouling in heat exchangers, while improving the performance of refrigeration and air-conditioning systems.

Project Impact

By moving to oil-less technologies, such as turbo-compressors, the project team can improve the overall performance of refrigeration and air-conditioning systems. These Improvements would lead to approximately 0.2 Quads of savings in commercial refrigeration alone.

Pouring in to the 3D-printed mold at the University of Northern Iowa.

Proof-of-principle rapid cast impeller.

Contacts

DOE Technology Manager: Antonio Bouza

Lead Performer: Ayyoub Mehdizadeh Momen, Oak Ridge National Laboratory

.......

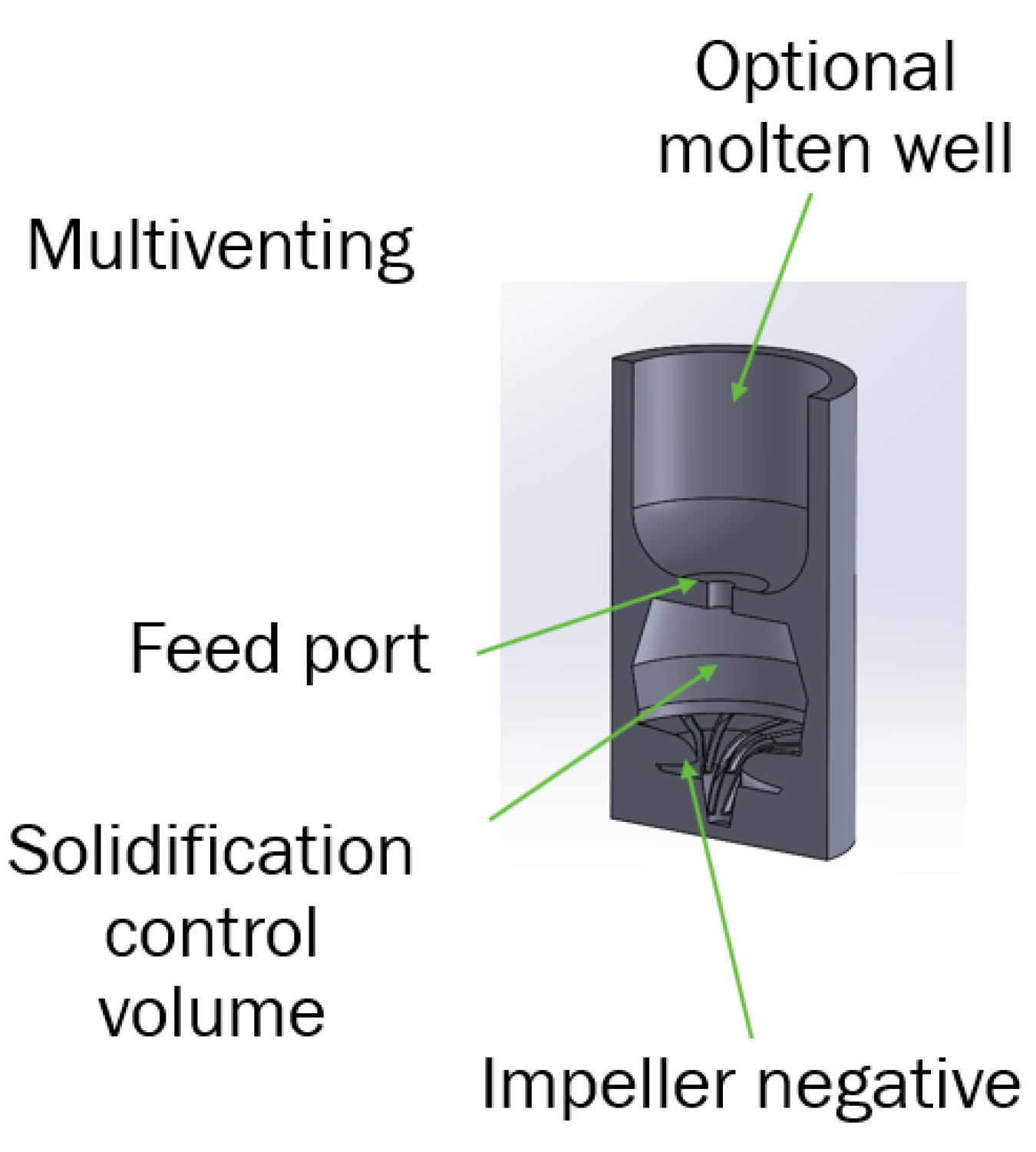

At right: Rapid cast impeller mold design.

.......

Related Publications