Lead Performer: Oak Ridge National Laboratory (ORNL) – Oak Ridge, TN

May 22, 2019

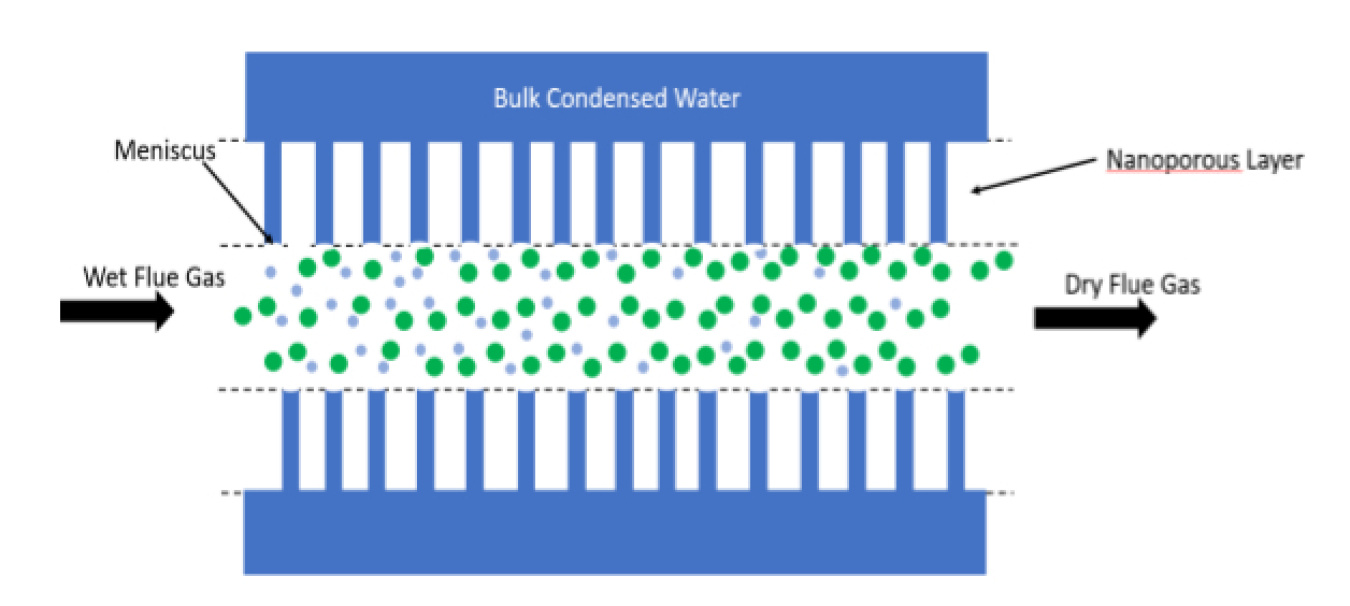

Nanoporous membrane “wicks” water from flue gases via capillary condensation; water is removed from gas stream quickly so does not absorb acid gases in flue gas.

Lead Performer: Oak Ridge National Laboratory (ORNL) – Oak Ridge, TN

DOE Total Funding: $400,000

Project Term: October 1, 2018 – September 30, 2020

Funding Type: Direct Funded

Project Objective

Current state-of-the-art high-efficiency natural gas furnaces obtain their high efficiency by recovering latent heat from the combustion products of natural gas. These combustion products include carbon dioxide, water, excess air, and small amounts of acid gases. The water vapor that condenses directly onto the furnace heat exchanger (HX) surface is acidic and corrosive. To avoid issues with corrosion, manufacturers must use expensive stainless steel or aluminum alloy materials for the condensing heat exchanger. To address these challenges, this project will investigate the possibility to use membrane technology to recover the latent heat (e.g., condense water) from the furnace flue gas and allow use of lower-cost materials. The eventual objective is achieve or improve on the overall efficiency of condensing furnaces while reducing installation cost by 10% or more.

Project Impact

This project will take a membrane-based approach to achieve condensing furnace efficiency levels (90%+ annual fuel utilization efficiency or AFUE) at lower cost than current high-efficiency natural gas furnaces.

Contacts

DOE Technology Manager: Antonio Bouza

Lead Performer: Ayyoub Mehdizadeh Momen, Oak Ridge National Laboratory

Prototype membrane/HX previously tested for potable water recovery from diesel engine exhaust à 98% reduced acid content; U.S. patent 9,394,672.