Lead Performer: University of Maryland – College Park, MD

November 3, 2020

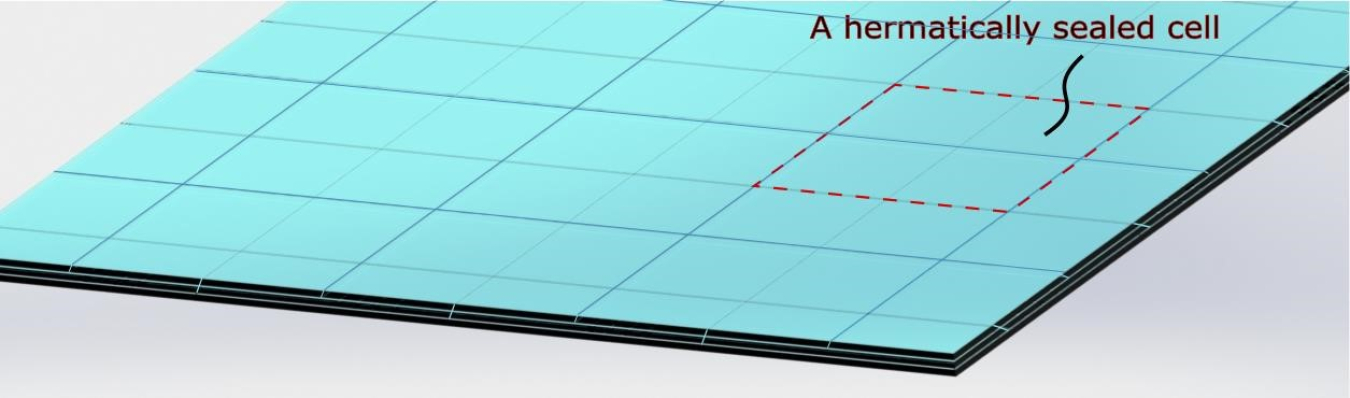

Schematic of vacuum insulated glass (VIG) construction.

Lead Performer: University of Maryland – College Park, MD

DOE Total Funding: $1,128,000

Project Term: May 2019 – April 2022

Project Objective

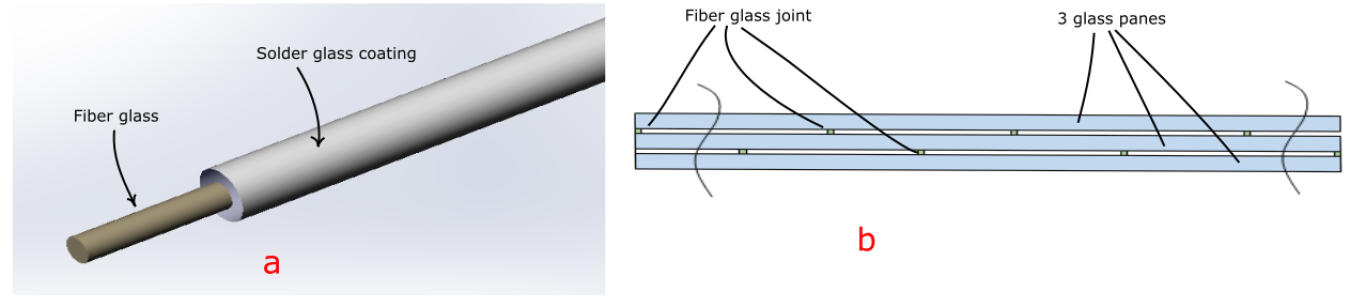

Billions of dollars flow out of windows every year in the form of energy losses. These losses can be cut by half or more by eliminating the gas between the glass panes and using the resulting vacuum to produce windows whose performance approaches that of the walls around them. Thin, lightweight, low-cost, vacuum insulating glass (VIG) windows are being developed. A center pane onto which a network of fine lines of low melting temperature glass has been deposited is sandwiched between two outer panes and fused within a vacuum furnace creating many independent, hermetically sealed cells resulting in massive increases in seal redundancy and reliability, which should minimize warranty claims. The manufacturing process can be easily integrated into existing glass manufacturing lines so the windows can be produced at large scale at a price point similar to standard double pane windows.

Project Impact

The VIG being developed would have minimal impact on window appearance, provide decreased acoustic transmission, and be highly reliable due to greatly increased seal redundancy. The overall thickness of the VIG will be about 12 mm (0.5").

Contacts

DOE Technology Manager: Marc Lafrance

Lead Performer: Ratnesh Tiwari, University of Maryland

Related Publications

Frit coated glass fiber (a) and triple pane VIG construction.