Lead Performer: Oak Ridge National Laboratory (ORNL) — Oak Ridge, TN; Partner: University of Connecticut — Storrs, CT

April 8, 2019

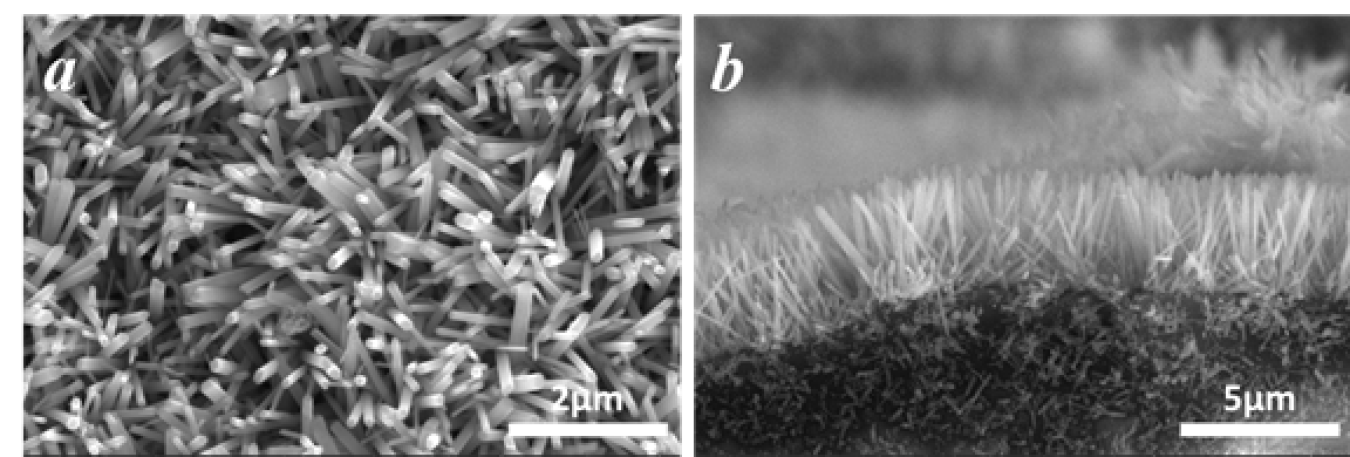

Figure 1: Scanning electron microscopy (SEM) images of ZnO nano-array on the cordierite: (a) top view; (b) cross-section view.

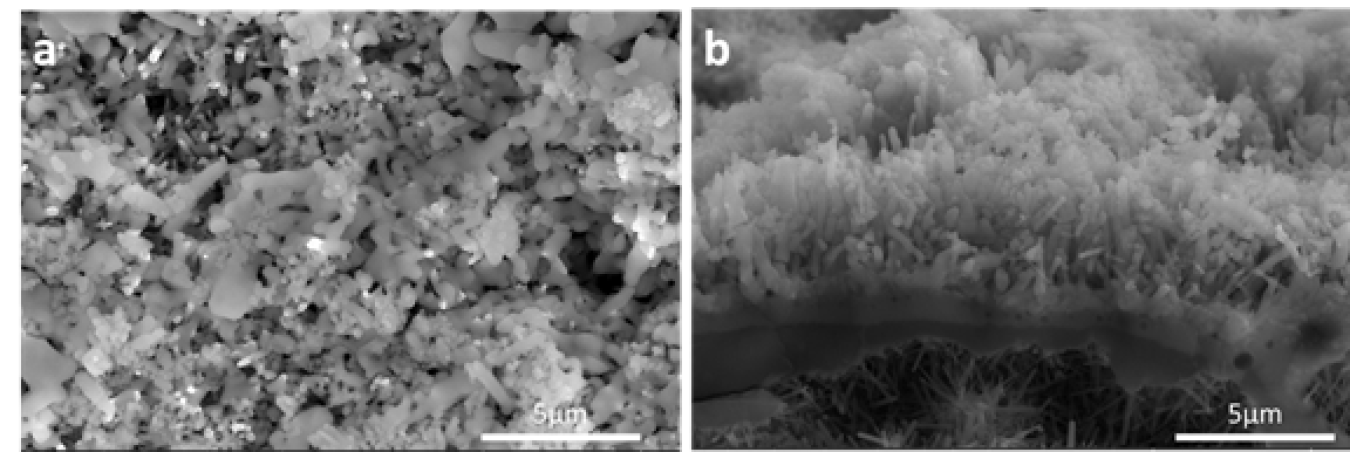

Figure 2: Scanning electron microscopy (SEM) image of BaCO3 nanoparticles washcoated ZnO nano-array, (a) top view; (b) cross-section view.

Lead Performer: Oak Ridge National Laboratory (ORNL) — Oak Ridge, TN

Partner: University of Connecticut – Storrs, CT

DOE Total Funding: $960,000

FY19 DOE Funding: $480,000

Project Term: October 1, 2018 - September 30, 2020

Funding Type: Direct Funded

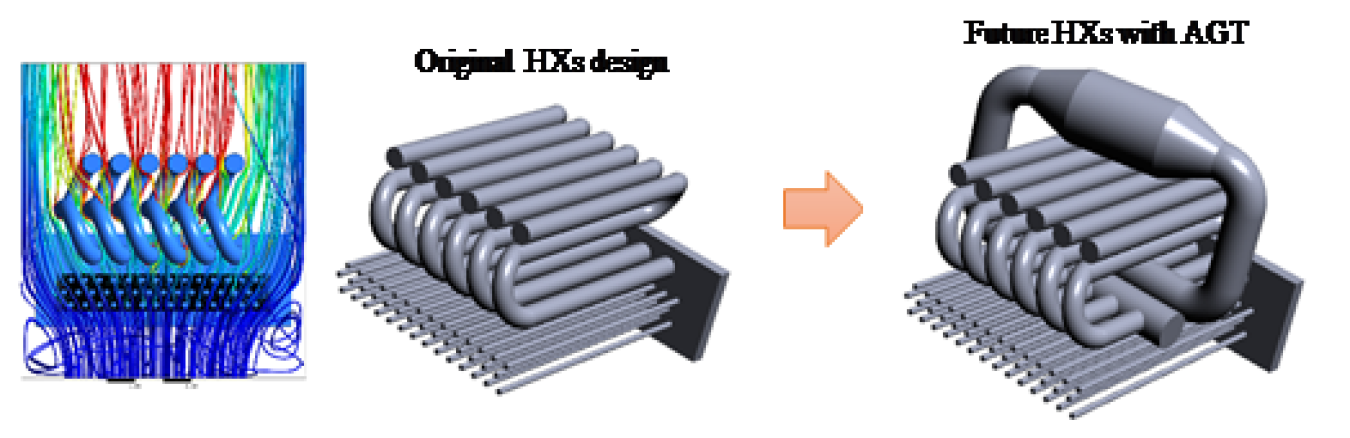

Project Objective

Many U.S. homes have furnaces with non-condensing units that only achieve about 80% AFUE due in part to the steep cost of high-efficiency condensing furnaces. To address the issue of affordability, this project will develop high-efficiency, condensing natural gas furnace technology, which adds a low-cost nano-array monolith trap. This will provide acidic gas removal that will enable the production of energy-efficient natural gas furnaces at a low cost. The acidic gas trap (AGT) uses low-cost alkali or alkaline earth metal oxides (e.g., Ba, Sr, Ca, Li, K, or Na) without precious metals, and is designed to maximize the acidic gas storage capacity. The AGT absorber will be integrated with the furnace heat exchangers, and continuously adsorb the acidic gases from the flue gas. Since the AGT absorber traps acidic gases, a large, second low-cost heat exchanger could be used to achieve the higher furnace efficiency by minimizing exhaust temperature. The overall objective of this project is to design a natural gas furnace with newly developed AGT technology that is both cost competitive and energy efficient.

Project Impact

The high-efficiency condensing furnace developed in this project will provide significant reductions in residential energy consumption with an AFUE rating greater than 98%. The AGT technology will provide a low-cost solution to safely and effectively absorb acidic gases.

Contacts

DOE Technology Manager: Antonio Bouza

Lead Performer: Zhiming Gao, Oak Ridge National Laboratory (ORNL)

Figure 3: Preliminary acidic gas trap (AGT) design based on CFD simulation.

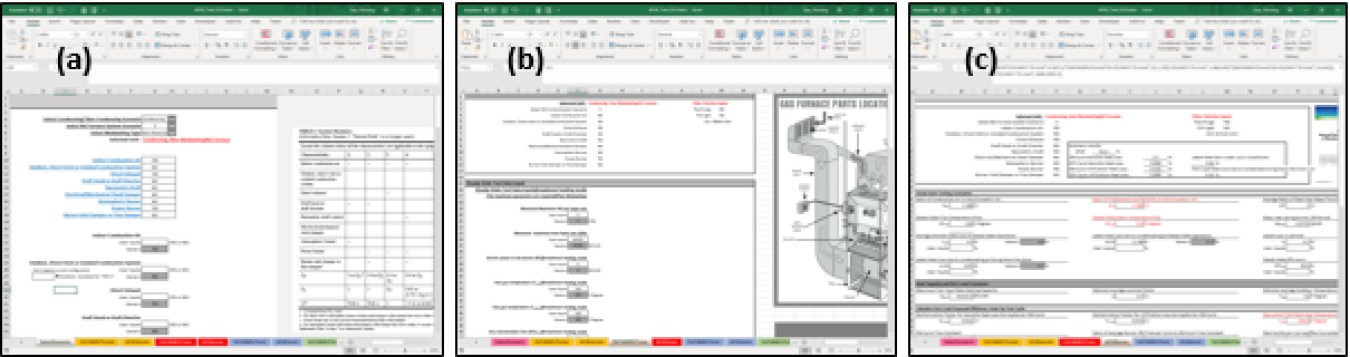

Figure 4: AFUE Analysis Tool, (a) unit and configuration selection; (b) geometry and measurement data inputs; (c) results: AFUE and other key data.

Related Publications

Z. Gao et.al., Advanced adsorption technology for new high-efficiency natural-gas furnace, Invention Disclosure 201804153, DOE S-138,820, 2018.

Z. Gao et.al., Advanced adsorption technology for new high-efficiency natural-gas furnace, Building Technologies Office 2019 Peer Review, April 15-19, 2019.