Bioprose Blog: The Feedstock-Conversion Interface Consortium shares highlights from 2020 and plans for 2021

December 8, 2020

Technology Manager, Conversion Research and Development

Read Beau's bio ►

Meet the other bloggers ►

Return to Bioprose blog ►

BIOPROSE BLOG

As Richard Hess noted in a recent Bioprose blog, variability is ubiquitous when working with lignocellulosic feedstocks. For many years it was assumed that equipment used to handle and process other applications (such as the corn grain or paper and pulp industries) would also be suitable for lignocellulosic biomass feedstocks. Unfortunately, experience has shown this not to be the case. These feedstocks are highly variable — even corn stover harvested from a single plot can have widely different levels of quality.

In the face of many new challenges (virtual meetings, lab shutdowns, stay-at-home orders), 2020 proved to be a very productive year for the Feedstock-Conversion Interface Consortium (FCIC). Funded by the U.S. Department of Energy’s (DOE’s) Bioenergy Technologies Office and working across nine DOE National Laboratories and a handful of industrial partners, this Consortium has made great strides in improving the fundamental scientific understanding of how biomass can be processed into biofuels and bioproducts.

Studying Variability to Enhance Feedstock Quality

Understanding the origins and extent of this variability is the first step towards managing it. In 2020, the FCIC catalogued sources of variability including harvesting methods, biomass storage conditions, and the impacts of environmental factors such as drought. Moreover, the Consortium has cast a broad net on what constitutes feedstock quality, looking far beyond the usual suspects of moisture content, average particle size, and total ash content. These attributes include:

- The presence of inorganic species that cause increased wear and abrasion on preprocessing equipment

- The existence of molecules that are toxic to microorganisms or cause catalysts to deactivate

- The molecular nature of the biomass polymers themselves, which impacts how they can be stored.

Fieldside storage of corn stover bales in Iowa. Researchers have found that under suboptimal storage conditions, biomass polymers can break down which can cause stacks of biomass to collapse or deform. Photo by Idaho National Laboratory (INL)

FCIC FY2020 Highlights

Throughout 2020, the Consortium has generated important scientific knowledge as well as tools that the biomass industry and other researchers can leverage. These findings span the biomass supply chain and include the following highlights:

- Materials scientists at Oak Ridge and Argonne National Laboratories have identified which fractions of woody residues are most abrasive on preprocessing equipment and precisely which mineral species are responsible. This information can help determine the best materials to use in preprocessing equipment and highlight the advantages or costs of additional preprocessing to remove troublesome components.

- It is long known that corn stover bales degrade over time, but what is happening at the tissue and molecular level has been less understood. This past year, teams at Idaho and Los Alamos National Laboratories have uncovered a wide range of impacts that result from this degradation, including increased roughness, the migration of inorganic species within the biomass, and even molecular rearrangements of lignin. These results will allow feedstock suppliers and consumers to evaluate storage method and feedstock quality tradeoffs.

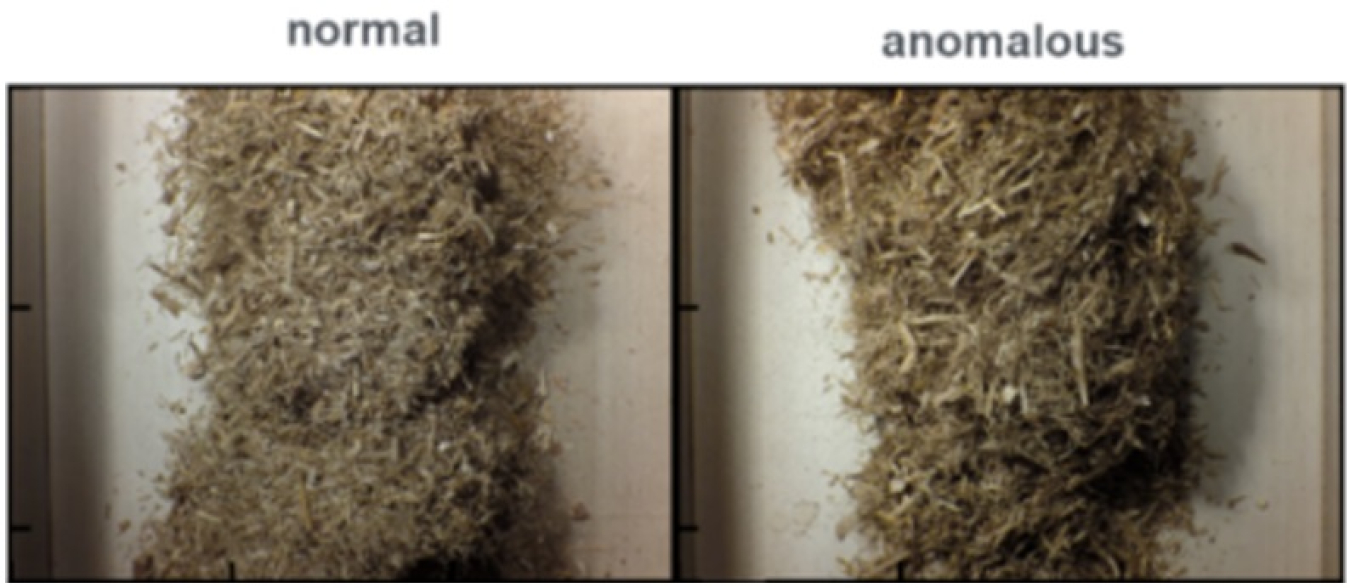

- Engineers at the National Renewable Energy Laboratory used a high speed camera to analyze over 20,000 unique images of biomass on a conveyer. After employing machine learning and artificial intelligence algorithms, they were able to train the camera to accurately identify “anomalous” biomass more than 97% of the time. This can enable low-cost control systems to help plant operators predict and prevent these anomalous biomass samples from causing process interruptions.

Examples of ‘normal’ vs ‘anomalous’ corn stover. Images were processed with models that identified characteristics such as stringiness in the anomalous material, which correlate with downstream process issues. Credit: NREL

What's In Store for FY2021?

What can we expect from the Consortium in 2021? Here are a few teasers:

- The FCIC is launching a technical webinar series starting in December and continuing into the spring. These webinars will cover select topics such as advancements in biomass modeling and the origins and extent of feedstock variability. We encourage you to register to attend our first webinar on December 09, 2020 and share with us feedback about which subjects interest you most!

- Each task in the Consortium will be presenting at the 2021 Bioenergy Technologies Office Peer Review in March 2021. These presentations will be open to the public and the presentation materials will be published online shortly thereafter.

- Techno-economic and life cycle analysts are hard at work preparing case studies and cost-benefit analyses for many of the tools and technologies that are being developed. For example: what is the most cost-effective way to prevent bale degradation while simultaneously maintaining biomass quality? Or, will I be able to save money (by avoiding replacement costs) if I use an advanced alloy in my preprocessing system? The Consortium is planning to prepare and publish over 15 of these case studies in the next year.

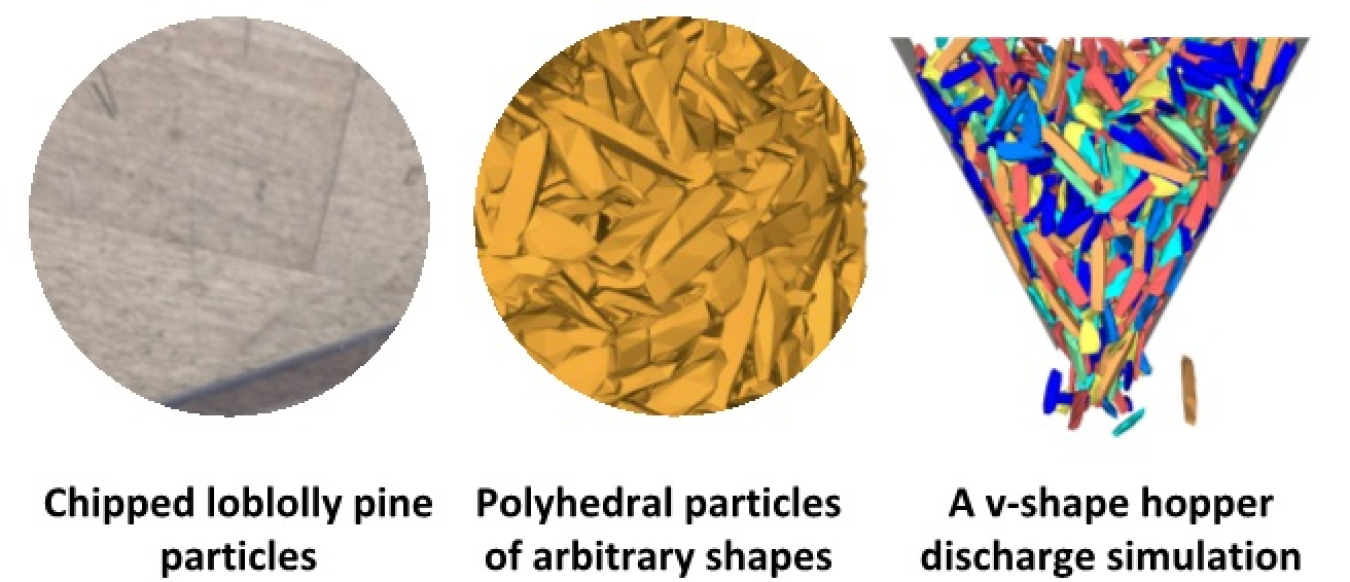

- The Consortium plans to publish several experimentally validated models onto GitHub that will be free-to-use by the biomass research community. These will include models that characterize particle behavior in preprocessing equipment and reaction performance models to predict fuel yields and quality.

Example of a particle model developed at INL. Researchers employed CT-scans of pine to develop high-resolution particle shape and size distributions. Photo credit: INL

- The Consortium will be systematically characterizing the criticality of biomass variability attributes and processing parameters across the process supply chain. The Biomass Feedstock Library is being updated to reflect the ranges that have been observed for each of these biomass attributes to help the community understand the extent of variability that can be expected

I encourage all our stakeholders to visit the FCIC webpage and learn more about the Consortium and the work being done to understand and mitigate the effects of feedstock and process variability on biomass harvest, storage, preprocessing, and conversion processes.