Bioprose Blog: Feedstock Conversion Interface Consortium researchers use advanced techniques to analyze biomass.

October 1, 2020Bioprose Blog

Bioenergy researchers have long recognized that one of the biggest challenges in converting biomass into biofuels, biopower, and bioproducts can be summed up with one word: variability. Variability in characteristics, such as moisture content, ash content, particle size, and chemical composition, can cause a wide range of challenges, from dry matter loss during storage to clogged equipment during preprocessing to poor yields during conversion.

For the past few years, much of the research on biomass variability has focused on two sources of variability: moisture and ash (either dirt or the inorganics found in biomass tissues). However, new research from the Feedstock Conversion Interface Consortium (FCIC) suggests that understanding the true complexity of biomass variability involves a slew of factors that impact biomass quality from harvest through conversion. The FCIC is a collaborative effort among nine Department of Energy National Laboratories dedicated to improving the overall operational reliability of biorefineries.

Over the course of multiple studies, researchers used advanced techniques to analyze biomass, such as fluorescence lifetime imaging, analytical pyrolysis coupled with gas chromatography-mass spectrometry, and machine learning. With these techniques, researchers took an in-depth look at variability including:

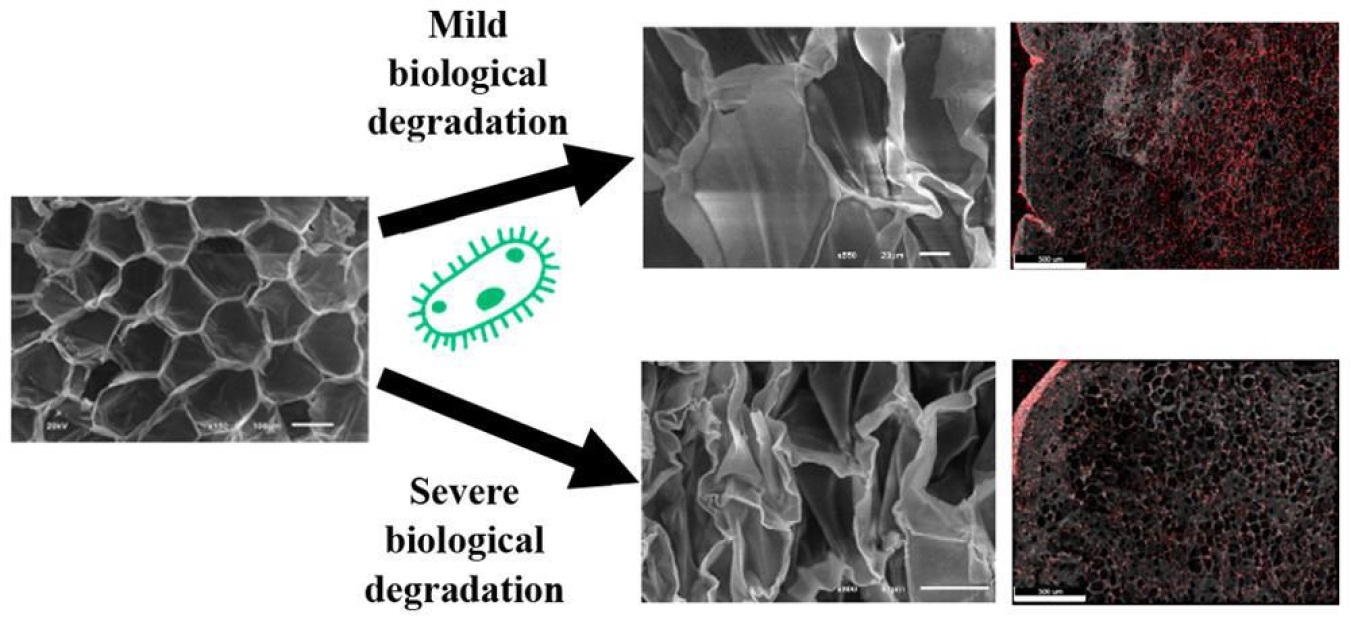

- Effects of biological degradation during storage on cell wall structures and the properties of different anatomical fractions of biomass

- Biomass variability at different scales (e.g., macroscale, microscale, and nanoscale)

- Variability at different harvest locations

- Impact of ash on the surface cohesion of molecules.

The research addresses a number of variability challenges that have plagued pioneer biorefineries.

Biomass

Biomass — anything from wood chips to sorted municipal solid waste — doesn’t flow through machinery as easily and is more variable than, for example, grain or oil. Consequently, biofuels producers have faced challenges during biomass preprocessing operations, the step right before the biomass gets turned into fuel.

A single clogged screen, hopper, or conveyor belt, or a piece of machinery prematurely worn down by excess silica (i.e., sand), can shut down the entire biorefinery until the problem is fixed. As a result, pioneer commercial-scale biorefineries have struggled to achieve anything close to their production capacity. Even after preprocessing is complete, variability challenges can hamper the conversion process. For instance, high levels of ash or potassium can reduce the efficiency and biofuel yield of conversion pathways.

The new research confirms that variability challenges in biomass go beyond simply mitigating moisture and ash. For example, one study from Idaho National Laboratory suggests that—much like two vineyards growing the same type of grapes might produce two vastly different bottles of wine—biomass variability involves everything from harvest method to weather to soil chemistry.

Two screw augers, one new (foreground) and one eroded (background), which was pulled from the machinery for rebuilding. Photo credit: Quang Nguyen

Corn Stover

Researchers looked at corn stover (i.e., the leaves, stalks, and cobs left over after corn is harvested) from farms in four different Iowa counties and analyzed 16 different attributes to determine variability and its impacts. The researchers used a multiscale approach to look at these attributes—for instance, the macroscale might assess the mechanical properties and behavior of leaves and stalks, the microscale might examine surface roughness or texture on individual particles, while nanoscale approaches can capture molecular changes in cell wall biopolymers.

One interesting, if not surprising, result is that data clustered by counties of origin and data from adjacent counties clustered together is not unlike two vineyards in the Bordeaux region of France producing bottles of wine that are more similar to each other than to two vineyards in Napa Valley, California. In the future, this type of analysis might help identify problematic soil chemistries or other factors that may influence biomass storage, preprocessing, or conversion. For example, high potassium levels are known to be detrimental to downstream conversion, and the methods developed in the study may help identify fields that produce corn stover that is high in potassium.

Ash Content

Another study, this time from researchers at Los Alamos National Laboratory, looked at the relationship between ash content and the surface properties of biomass such as cohesion. The researchers found that increases in ash content—from physiological sources, such as the stems of plants or from external sources, such as dirt picked up during harvest—led to increases in cohesion of corn stover. The increased cohesive nature of corn stover with high ash content could mean more feeding and handling challenges, such as clogged equipment. In short, high ash content makes it harder for corn stover to flow easily through machinery.

Knowing how ash content impacts surface cohesion could help researchers develop harvest techniques that are better at preventing soil from contaminating crops such as corn stover. Or researchers could separate out different anatomical fractions—i.e. leaves, stems and cobs—and blend high ash content fractions with other, low-ash sources biomass types to meet biorefinery specifications.

Storage

Several studies looked at how self-heating and microbial degradation during storage impact the microstructure of corn stover. Researchers investigated how:

- Degradation affects the distribution of elements within different anatomical fractions

- Degradation leads to structural and molecular changes

- Self-heating impacts surface properties such as texture, surface area, and porosity

- Self-heating results in changes to cell structures that lead to an increase in properties such as brittleness

The researchers found that self-heating and microbial degradation can impact corn stover’s physical and chemical properties—again creating variability that could impact downstream processes such as preprocessing and conversion.

Five photos showing comparative mild and severe degradation of corn stover. Image credit: INL

This work, supported by the Bioenergy Technologies Office, could help to inform best management practices for harvest, collection, and storage and the development of selective preprocessing strategies that limit wear and abrasion for enhanced conversion.

All told, using advanced characterization techniques to understand the depth and breadth of biomass variability at multiple scales can help the biomass industry to understand how biomass behaves and to design processes that can deal with variability.