Members of Energy I-Corps Cohort 12

The opening session for Energy I-Corps Cohort 12 was held March 22–26, 2021, and the closing session was held May 11–13, 2021.

Cohort 12 was composed of 18 teams from Argonne National Laboratory (ANL), Idaho National Laboratory (INL), Los Alamos National Laboratory (LANL), Lawrence Berkeley National Laboratory (LBNL), National Energy Technology Laboratory (NETL), National Renewable Energy Laboratory (NREL), Pacific Northwest National Laboratory (PNNL), and Sandia National Laboratory (SNL).

Cohort 12 was the largest-ever Energy I-Corps cohort at the time. Dubbed the "Mega Cohort," the entirety of Cohort 12 was held virtually due to the COVID-19 pandemic.

Teams and Technologies

Team Members

- Principal Investigator: Jim Coons

- Entrepreneurial Lead: Colleen Pastuovic

- Industry Mentor: Ann Adams

Technology Description

Separations exist in all manufacturing sectors. For the food and beverage sector specifically, separation technologies such as centrifugation and filtration are well established. However, these current separation solutions are time-intense, require skilled operators, and can reduce yield and product quality. Researchers at LANL are developing a particle concentrator based on silent ultrasonic waves. UltraSep will target continuous flow processes at scales relevant to industry. Its membrane-less operation provides steady particle removal without the need for disruptive backwashing, filter-cleaning, or expensive maintenance. This filter-less technology will reduce energy use, improve separations, reduce waste, and cut manufacturing costs.

Team Members

- Principal Investigator: Luis Diaz Aldana

- Entrepreneurial Lead: Mark Strauss

- Industry Mentor: Juan Carlos Villatoro

Technology Description

The EC-leach process is based on the use of electrons as a green reagent for the extraction of critical and strategic materials (Co, Mn, Ni, Cu, and Li) from end-of-life LIBs. Through this process, high extraction efficiencies (>98%) can be achieved at high pulp densities and in a hydrogen-peroxide-free environment. The process is based on the use of an electrochemically active reducing agent, which can be continuously regenerated during the extraction process.

Team Members

- Principal Investigator: Suh-Jane Lee

- Entrepreneurial Lead: Wenbin Kuang

- Entrepreneurial Lead: Leo Fifield

- Industry Mentor: Dr. Philip Taynton

Technology Description

Vitrimers are a new class of engineered plastics that are weldable, repairable, and recyclable like thermoplastics but have high-mechanical properties like thermosets. Vitrimers have great potential in enabling reprocessing of scrap from production an end of life components. The PNNL-developed CO2-derived vitrimer technology offers advantages such as reduction of greenhouse gas by converting CO2 to a value-added material for various applications such as automotive components, electronic components, construction materials.

Team Members

- Principal Investigator: Juan A. Lopez-Ruiz

- Entrepreneurial Lead: Ismael Rodriguez-Perez

- Industry Mentor: Jeff Presley

Technology Description

As regulations of pollutant levels in treated water become stricter, the water treatment infrastructure will need new technologies to remove pollutants. Our technology uses electricity to remove pollutants from wastewater more efficiency that current technologies. This technology operates at room temperature, does not require the addition of chemicals to degrade the pollutants, and allows the construction of modular water treatment units that require little maintenance. Our technology selectively generates hydrogen and volatile hydrocarbons (ethane, ethylene, etc.) from the decomposition of pollutants, which can be used to power fuel-cell vehicles and for distributed heat and power generation.

Team Members

- Principal Investigator: Di-Jia Liu

- Entrepreneurial Lead: Haiping Xu

- Entrepreneurial Lead: David Carter

- Industry Mentor: Michael Gurin

Technology Description

Our technology concerns the direct electrocatalytic conversion of CO2 to chemicals. CO2 is a valuable feedstock in the carbon circular economy. Converting the chemically inert CO2 to valued-added chemicals has been challenging because of its low-process energy efficiency. Our team recently developed a patented, award-winning, amalgamated lithium metal method and synthesized a family of highly selective, energy-efficient electrocatalysts for converting CO2 to various C1 to C3 chemicals (2020 R&D 100 Award). The work caught significant interests from the industries ranging from chemical producers, cement makers, and biofuel producers, to wine and spirit makers.

Team Members

- Principal Investigator: Tao Dong

- Entrepreneurial Lead: Tuong Bui

- Industry Mentor: Alice Havill

- Industry Mentor: Tim Beranek

Technology Description

NREL has developed a process to produce next-generation renewable bio-based non-isocyanate polyurethane (Bio-NIPU) materials using precursors of amino acids (and peptides) and lipids. These versatile feedstocks—derived from vegetable, algae, and even waste fats, oils, and greases—are readily available, nontoxic, sustainable, easy-to-handle, and low-cost. The polymer products using NREL’s novel synthesis method are 100% bio-based and free of isocyanates, enabling the reduction of toxic waste streams and offering significant sustainability advantages over current commercial products.

Team Members

Principal Investigator: Carl Iverson

Entrepreneurial Lead: Joseph Dumont

Entrepreneurial Lead: Babs Marrone

Industry Mentor: Eric KlingenbergTechnology Description

We have been developing machine-learning (ML) tools to optimize monomer-to-polymer discovery and design, focusing on the shift away from petroleum-based plastics toward biopolymers. Polyhydroxyalkanoates are uniquely suited to fill this need. ML accelerates the development of suitable biopolymers from algae by matching large data sets of chemical structures to specific desired properties. We are also building a chemical knowledge base that will provide the foundation to advance the development of biopolymers for the manufacture of plastics for a wide range of applications and optimal end-of-life degradation. We are learning what makes a good bioplastic for packaging applications.

Team Members

- Principal Investigator: Daniel Hayes

- Entrepreneurial Lead: Christina Wildfire

- Industry Mentor: Kerry Hanahan

Technology Description

Microwaves have the potential to transform chemical production through the benefits of rapid and selective heating of active sites leading to uniform, on-demand bed temperatures and improved control over conversion and product selectivities. Our proposed process offers a route for the direct (single-step) conversion of remote natural gas resources into valuable chemicals like olefins and aromatics to reduce flaring and associated emissions. The proposed microwave-based system has a modular design and is more efficient with improved dynamic response covering electricity input and flow variations, making it desirable for conversion of stranded gas resources powered by renewables.

Team Members

- Principal Investigator: Clifford Ho

- Entrepreneurial Lead: Henk Laubscher

- Entrepreneurial Lead: Kyle Guin

- Industry Mentor: Steve Willard

- Industry Mentor: Gordon Ho

Technology Description

THERMS has developed a particle-based thermal storage technology that is inexpensive and increases the security and resilience of the electrical grid in the face of increasing natural disaster and intentional threats. THERMS uses inexpensive rock and/or sand-like particles that can be used for large-capacity, long-duration energy storage for electricity production or process heat. The team has developed unique designs for particle heating, storage, energy extraction, and conveyance. This technology can also be integrated with fossil-fuel, nuclear, and/or geothermal power plants to make those traditionally baseload electricity sources more flexible and dispatchable.

Team Members

- Principal Investigator: Hojun Lim

- Entrepreneurial Lead: David Montes de Oca Zapiain

- Industry Mentor: Mark Chavez

Technology Description

Our novel machine-learning solution is capable of instantly accounting for the load-dependent deformation in metallic alloys by rapidly and accurately predicting the constants that characterize this behavior. In addition, our solution does not need any expensive mechanical experiments or computationally intensive computational simulations to predict the value of these constants. As a result, our solution enables material scientist and manufacturers to develop realistic and accurate material deformation simulations 1,000 times faster than currently available software solutions. Therefore, our customers are able to shorten their design cycles and place products in the market faster and more-efficient way.

Team Members

- Principal Investigator: Isaac C Aviña

- Entrepreneurial Lead: Fred Patrick Doty

- Industry Mentor: Bill Hartman

Technology Description

EPDR offers a flexible electronic polymer dosimeter to more accurately administer radiation therapy to tumor locations, which provides lower-cost treatment and improves patient outcomes. The concept is a disposable adhesive patch based on electronic polymer particle detectors. The adhesive patch can be applied directly to the patient’s skin to precisely measure radiation intensity and spatial distribution at the points of entry. The greater precision of this technology will benefit patients and reduce operating and liability costs for treatment facilities by increasing efficacy (i.e., fewer treatments) and reducing collateral damage (i.e., fewer insurance claims).

Team Members

- Principal Investigator: Paul Torcellini

- Entrepreneurial Lead: Sammy Houssainy

- Industry Mentor: Peter Turnbull

Technology Description

As local, state, and national government agencies seek to create infrastructure, policy, and incentive frameworks to support energy-efficient mobility, there’s an increasing need for objective travel behavior data. e-Mission is an open-source platform that facilitates mobility data collection across all modes. The flexible platform allows agencies to assemble a customized system. The foundational modules include background sensing on smartphones, machine learning to process the sensed data into a multi-modal travel diary, and visualization elements. Long-term data collection coupled with the analytics incorporated into the platform help answer critical questions around of the efficiency of interventions.

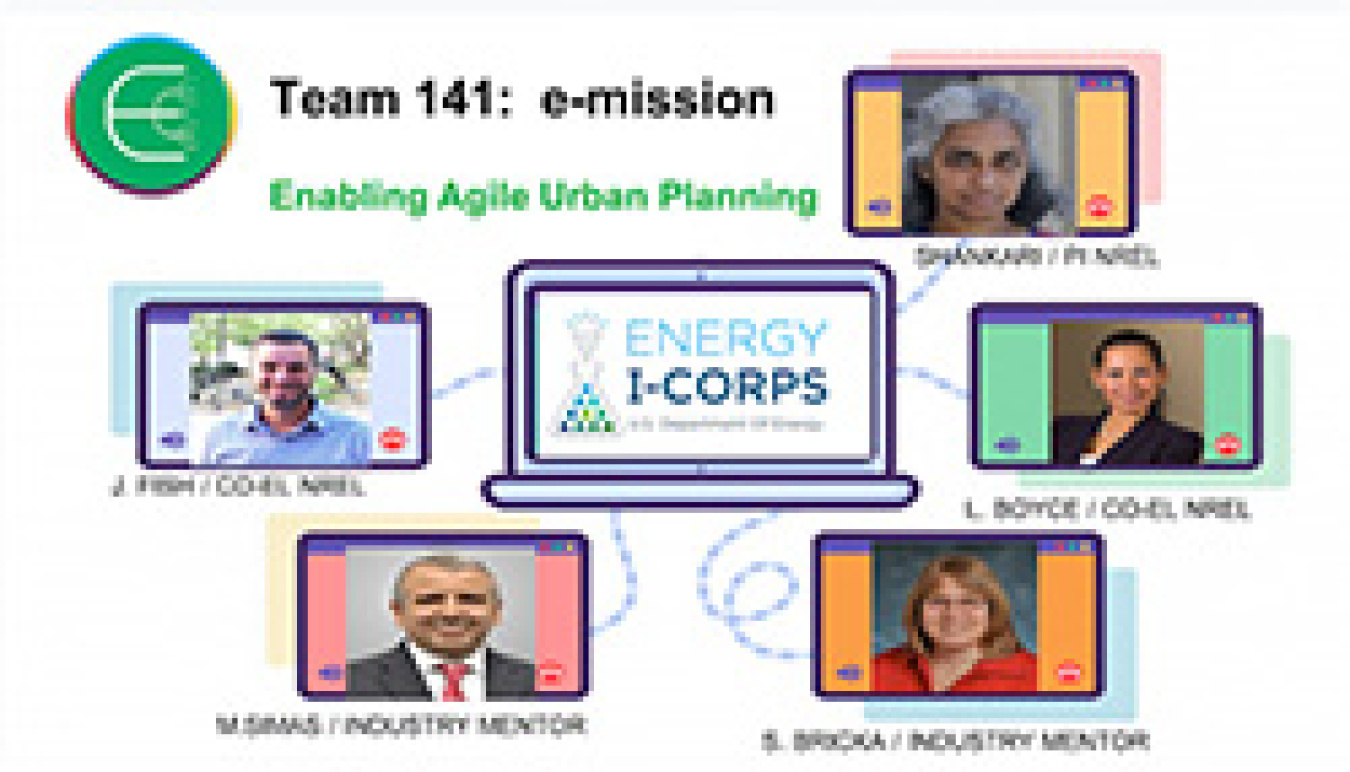

Team Members

- Principal Investigator: K. Shankari

- Entrepreneurial Leads: Joseph Fish, Leidy Boyce

- Industry Mentors: Marcelo Simas,Stacey Bricka

Technology Description

As local, state, and national government agencies seek to create infrastructure, policy and incentive frameworks to support energy-efficient mobility, there’s an increasing need for objective travel behavior data. e-Mission is an open-source platform that facilitates mobility data collection across all modes. The flexible platform allows agencies to assemble a customized system. The foundational modules include (i) background sensing on smartphones, (ii) machine learning to process the sensed data into a multi-modal travel diary, and (iii) visualization elements. Long-term data collection coupled with the analytics incorporated into the platform help answer critical questions around of the efficiency of interventions.

Team Members

- Principal Investigator: Ganesh Vijayakumar

- Entrepreneurial Lead: Andrew Glaws

- Industry Mentor: Gregory Oxley

Technology Description

INN-Design is a software framework for robust design of airfoils and wind turbine rotors using invertible neural networks (INN). The neural-network is trained using data generated by a machine learning enhanced computational fluid dynamics (CFD) pipeline with state-of-the-art modeling capabilities to accurately predict the three-dimensional, non-linear, aerodynamic response critical for optimal design of rotors. Our technology is 100 times faster than CFD-based design approaches while retaining a similar level of fidelity. This will enable integration of INN-Design into multi-disciplinary design and optimization cycles to reduce the levelized cost of wind energy.

Team Members

- Principal Investigator: Shawn Sheng

- Principal Investigator: Yi Guo

- Entrepreneurial Lead: Caitlyn Clark

- Industry Mentor: Mike Kelly

Technology Description

RBLO is a software tool that enables computationally efficient layout optimization of wind energy plants, accounting for power production and total wind plant cost of failure in a cost-of-energy-like metric. RBLO leverages other NREL-developed tools to assess reliability in high-risk components through experimentally validated, analytical-component models, and provides customized optimal plant layouts based on user-specified component design, wind conditions, control strategies, and operations and maintenance (O&M) strategies. RBLO enables users to explore the tradeoffs between power-production revenue and component-failure costs with the ultimate aim of improving wind plant reliability and reducing costly O&M—all while maintaining or enhancing power production.

Team Members

- Principal Investigator: Heidi Tinnesand

- Entrepreneurial Leads: Sagi Zisman, Dmitry Duplyakin

- Industry Mentor: Erika Boeing

Technology Description

Tools Assessing Performance (TAP) computational framework is a set of software tools that allow distributed wind stakeholders to calculate the wind resource at any location within the U.S. These tools utilize statistical methods, atmospheric science techniques, and modern computational capabilities using NREL's best-in-class WIND Toolkit to facilitate reliable accurate estimations of the wind resource. Distributed wind project decision makers can leverage TAP's data and tool set to mitigate project financial risk, increase return on investment, and generate new opportunities in the market.

Team Members

- Principal Investigator: Tianzhen Hong

- Entrepreneurial Leads: Kaiyu Sun, Jeetika Malik

- Industry Mentor: Lowell Chu

Technology Description

CityBES is a web-based data and computing platform providing energy modeling, benchmarking, district energy systems, and performance visualization of a city's building stock to achieve energy efficiency, demand flexibility, and resilience at district or city-scale. CityBES uses an international open data standard, CityGML, to represent and exchange 3D city models. CityBES employs CBES (an R&D 100 Award recipient) to simulate building energy use and calculate savings from energy retrofits. CityBES evaluates and optimizes technologies and strategies for 100% clean and resilient energy infrastructure for buildings. CityBES targets urban planners and developers, city energy managers, building owners, utilities, energy consultants and researchers.

Team Members

- Principal Investigator: Shiloh Elliot

- Entrepreneurial Lead: James Kershaw

- Industry Mentor: Jeff Smyth

Technology Description

IrrigationViz allows users to visualize what-if scenarios to explore the impact of various irrigation improvements. Users interact with a map to view the current infrastructure, make edits, and see the estimated costs and benefits from proposed upgrades.