-- This project is inactive --

SunTrough, under the Baseload CSP FOA, developed a new class of solar concentrators with geometries and manufacturability that can significantly reduce the fully installed cost of the solar collector field.

Approach

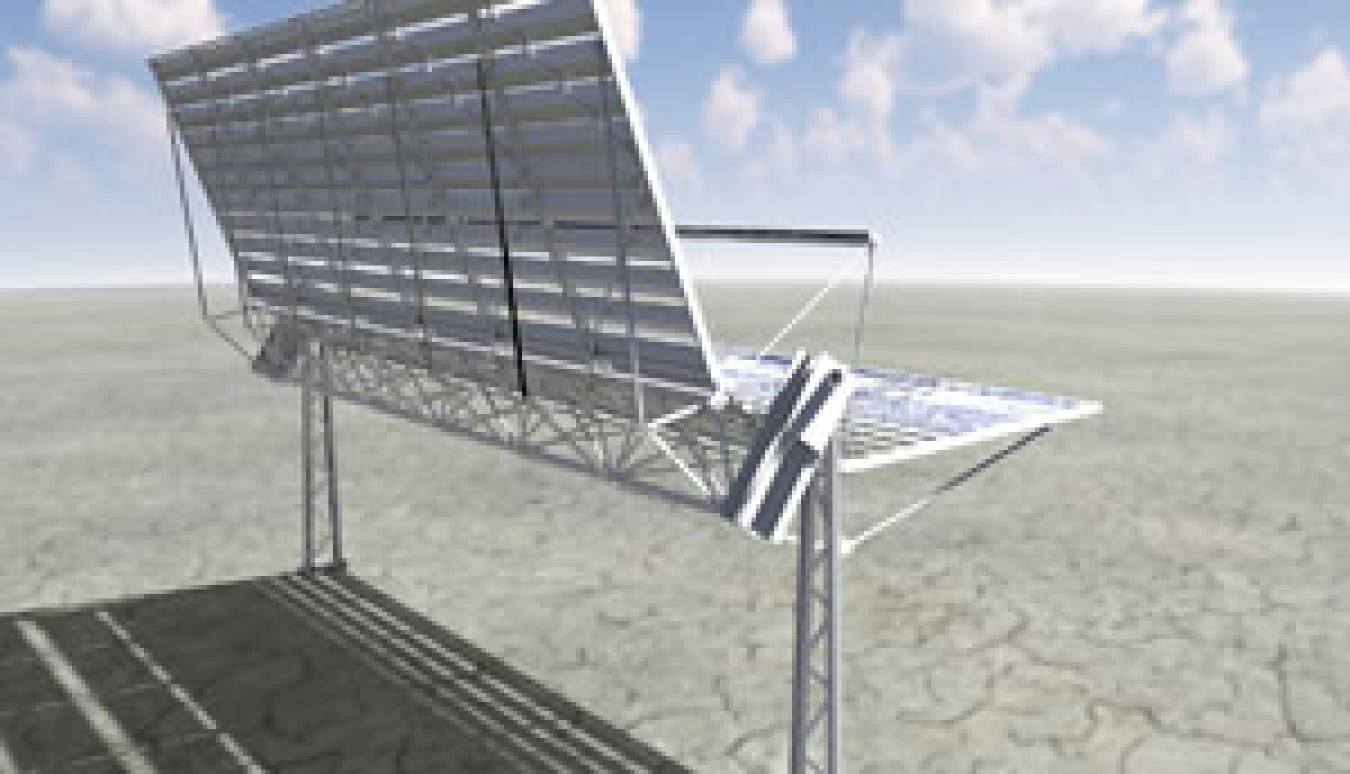

SunTrough Energy developed a single-axis tracking, line-focus solar concentrator and a pilot manufacturing facility under this award. The new Articulating Planar Fresnel Collector (APFC) design is supported by dedicated component manufacturing facilities and supply chain management.

Pictured is a single-axis tracking, line-focus solar concentrator based on articulating planar Fresnel collector geometry.

Innovation

The APFC incorporates the geometry of the linear Fresnel reflector with the single-pivot tracking of the conventional parabolic trough collector. This has two distinct advantages over existing CSP designs:

- Compared to a parabolic trough, the unit is subjected to lower wind loads, which translates into less structural support metal and smaller/simpler foundations and drives.

- Compared to a linear Fresnel, the unit eliminates the individually tracked mirror facets.

The design utilizes a stationary receiver and near-flat linear mirror sections assembled in a planar section. The APFC is designed with smaller, identical parts for mass manufacturability and rapid field integration.

Conclusion

The most notable accomplishment of this award was the delivery of a full-scale integrated design, manufacturing and field installation solution for a new class of solar collector architecture, which was classified as the Bi-Planar Fresnel Collector (BPFC) and may be considered as a viable alternative to the conventional parabolic trough, as well as the conventional Fresnel collectors. This was in part accomplished through the design and development, all the way through fabrication and test validation of a new class of linear planar Fresnel collector architecture. This architecture offers a number of key differentiating features, including a planar light-weight frame geometry with small mass-manufacturable elements utilizing flat mirror sections. The designs shows significant promise in reducing the material costs, fabrication costs, shipping costs, and on-site field installation costs compared to the benchmark “conventional” parabolic trough, as well as the conventional Fresnel collector.

In addition to delivering the design of this new class of collector architectures, the project also delivered hardware in the form of a full-scale fabricated prototype, along with proto-production assembly tooling. The fabricated tooling and prototype collector served as a validation of the design's manufacturability and its projected fabrication costs. Furthermore, on-sun field tests were also conducted on this prototype to evaluate performance and validate shipping and field “installability” costs.

Final Report

Ansari, Asif, Lee Philip, and Chirath Thouppuarachchi. Research and Development of a Low Cost Solar Collector. No DE-EE0003591, 2012. doi:10.2172/1069235.

Publications, Patents, and Awards

At this time, this project does not have published articles, patents, or awards.

Learn about other concentrating solar power research.