Energy I-Corps helped shape the entrepreneurial mindset behind a solvent-based mineral recovery breakthrough.

Office of Technology Commercialization

September 9, 2025Some breakthroughs don’t start with success—they start with a pivot.

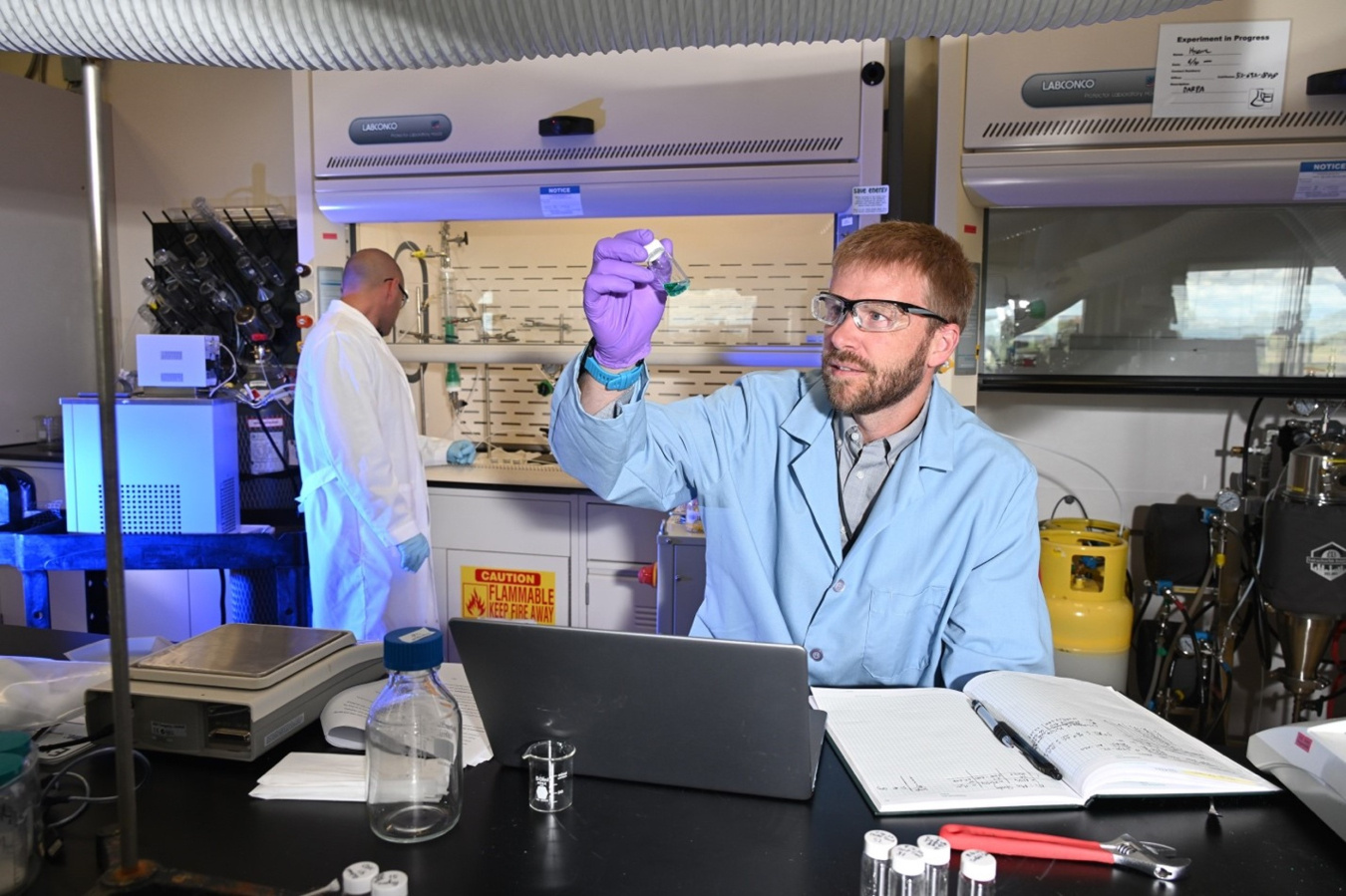

For Idaho National Laboratory (INL) researcher Aaron Wilson, the journey from concept to commercial impact didn’t follow a straight line. But with guidance from the U.S. Department of Energy’s (DOE) Office of Technology Commercialization’s Energy I-Corps program—an intensive, 2-month commercialization training designed to help National Laboratory teams bring their technologies to market—Wilson found a new direction, and a new way of thinking, that would reshape his work in the lab for years to come.

In 2015, Wilson joined the first-ever Energy I-Corps cohort (then called Lab Corps) with a promising water treatment concept called switchable polarity solvents. The technology showed potential, but when the team couldn’t meet the performance metrics required for follow-on funding, Wilson knew it was time to reassess. The entrepreneurial skills and sharper market perspective he gained through Energy I-Corps inspired Wilson to look beyond well-worn solutions. “There are a lot of water treatment technologies out there,” he said. “And collectively, we had been rehashing the same ones for more than 40 years. We needed to come up with something truly different.”

That industry-focused mindset took shape during Wilson’s time in Energy I-Corps. “The program pushed me to continually evaluate markets and keep talking with people,” Wilson said.

What followed was an unexpected but game-changing shift in direction. Wilson investigated an old process (solvent-driven crystallization) with a new solvent (dimethyl ether) that is highly recyclable. His team discovered that the mechanism behind solvent-driven crystallization worked differently than was commonly believed. Rather than changing the chemical properties of the solvent, they found that the solvent molecules were competing with salts for water, essentially stripping water molecules away and forcing the salts to crystallize out. This insight led to a new scientific model and paved the way for a more efficient and energy-saving approach to water filtration and mineral recovery.

With this new understanding, the team pivoted to a new technique called dimethyl ether fractional crystallization (DME FC). This process recovers critical minerals and salts with exceptional efficiency and minimal energy use.

The science behind DME FC is impressive. The process avoids energy-intensive steps like drying or evaporation and achieves over 95% recovery for some salts, and up to 99.9999% recovery of the solvent itself under experimental conditions.

The process has already demonstrated strong potential across a wide range of complex solutions, including battery and magnet recycling, acid mine drainage, and industrial byproducts. It is rapidly advancing toward real-world application, with multiple licenses secured, active scale-up efforts in collaboration with industry partners, and recognition through a 2023 R&D 100 Award.

The Switchable Polarity Solvents technology has resulted in three licenses and two patents since the team’s participation in Energy I-Corps. Additionally, Wilson’s team was awarded $750,000 in funding to continue to develop and deploy this technology through multiple follow-on projects.

Today, Wilson’s team leads a diverse portfolio of projects all grounded in a focus on real-world application and commercial impact. “We don’t continue to develop a technology if it doesn’t have industrial potential,” Wilson said. That principle has helped the INL group secure several licenses for work done within the DOE Critical Materials Innovation Hub and contribute to DOE’s Minerals to Materials Supply Chain Research Facility program, which builds upon existing efforts to accelerate the establishment of new, domestic critical minerals and materials supply chains.

One lesson that stuck with Wilson came from Energy I-Corps instructor Peter Fisk: the importance of diversifying while staying focused. Today, Wilson’s team applies that approach across 10 active projects, each targeting different markets, but all rooted in the same core technical foundation. This approach allows them to scale impact without losing strategic direction.

To Wilson, commercialization means making science useful. “You’ve got to be able to explain why your work helps people,” he said. “That’s what Energy I-Corps taught me: focus on the real-world problem and then go build something that matters.”