The Portsmouth Paducah Project Office recently met a DOE Office of Environmental Management priority for 2025 after successfully converting more than 1,000 cylinders of depleted uranium hexafluoride into a safer, more stable oxide form. August 26, 2025

Office of Environmental Management

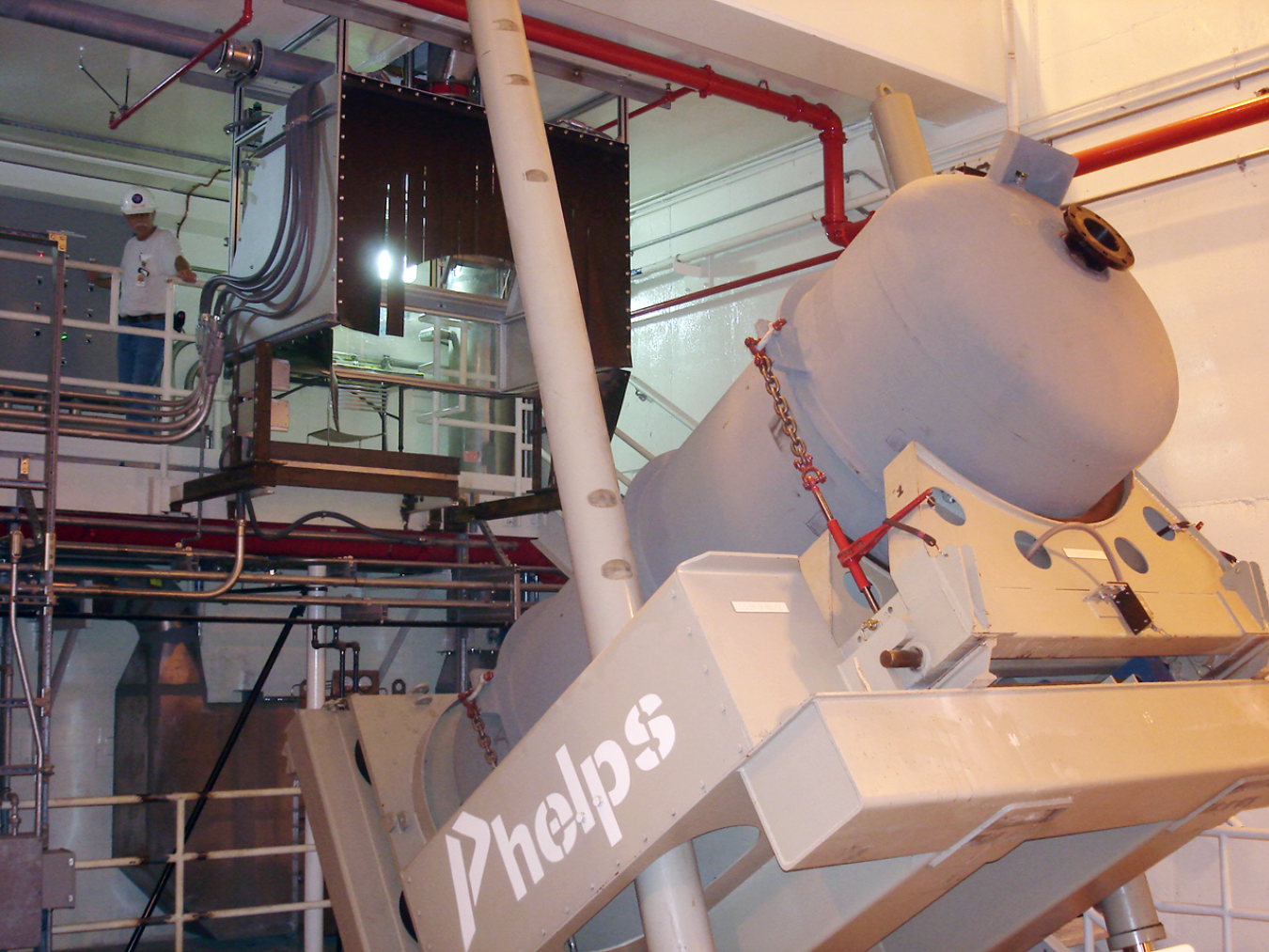

August 26, 2025Technicians at the Paducah Depleted Uranium Hexafluoride Conversion Facility monitor operations as the 1,000th cylinder of depleted uranium hexafluoride is safely processed into a stable oxide form, marking a major 2025 priority for the U.S. Department of Energy Office of Environmental Management.

LEXINGTON, Ky. — The Portsmouth Paducah Project Office recently met a U.S. Department of Energy (DOE) Office of Environmental Management priority for 2025 after successfully converting more than 1,000 cylinders of depleted uranium hexafluoride (DUF6) into a safer, more stable oxide form.

The DUF6 team reached the milestone through coordinated operations at the Paducah, Kentucky, and Portsmouth, Ohio, legacy nuclear sites, which are central to the nation’s uranium enrichment history.

The DUF6 material, a coproduct of decades of uranium enrichment for defense and commercial energy purposes, poses long term storage and environmental challenges in its original form. Through conversion to uranium oxide, the DUF6 team is helping mitigate those risks and advance DOE’s cleanup mission.

“Reaching this milestone demonstrates the team’s excellence in efficient operation of the DUF6 plants,” DUF6 Program Manager Zak Lafontaine said. “The team's consistent operation of the facilities, coupled with a stellar safety record, are essential to our continued success.”

The conversion process involves chemically transforming DUF6 into uranium oxide powder, which is significantly less reactive and safer to manage for reuse or disposal. The oxide is then packaged in robust containers and shipped to a licensed disposal facility.

At the Paducah Depleted Uranium Hexafluoride (DUF6) Conversion Facility, a cylinder is positioned to collect uranium oxide powder from the storage hopper. This process is part of converting DUF6 into a more stable uranium oxide for safe long term storage and management.

“This is more than just a number. It’s a reflection of our team’s dedication to safety, precision and environmental responsibility,” Mid-America Conversion Services (MCS) Project Manager Dutch Conrad said. “Every cylinder we convert brings us one step closer to a safer future for the communities around Paducah and Portsmouth, and for the nation as a whole.”

MCS is the contractor for the DUF6 project.

The DUF6 project draws from innovative methods and technologies to manage and convert DUF6 into usable materials, ensuring compliance with all safety and environmental regulations. The Portsmouth Paducah Project Office conducts operations of the DUF6 conversion plants as required by Public Law 107-206.

-Contributor: Kearney Canter

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.