Scientists develop a new approach for detecting defects in metal parts produced by additive manufacturing.

June 6, 2025The Science

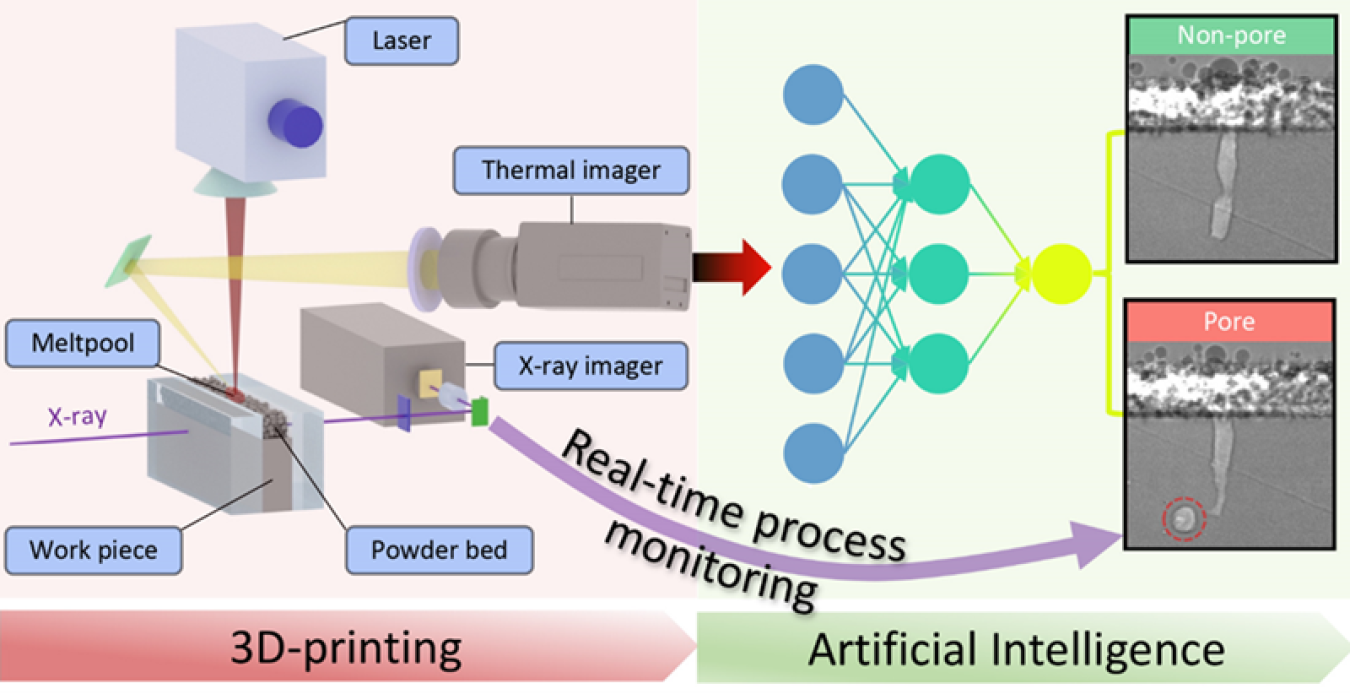

Structural defects that form during additive manufacturing, also known as 3D printing, are a barrier to some applications of this technology. Researchers used diagnostic tools and machine learning to develop a new method for detecting and predicting defects in 3D printed materials. This method could transform the 3D printing process. The method uses various imaging and machine learning techniques to detect the generation of pores in real time with near-perfect accuracy. Next, the researchers will develop sensing technologies that can detect other types of defects that occur during the additive manufacturing process. The goal is to create a system that not only detects defects but can enable repairs during 3D printing.

The Impact

Many industries rely on metal additive manufacturing to rapidly build complex parts and components. This process involves building parts layer by layer with a 3D printer. Industry now uses 3D printing to make everything from rocket engine nozzles to pistons for high performance cars to custom-made orthopedic implants. New advanced diagnostic tools to detect and potentially repair defects will expand the use of additive manufacturing in aerospace and other industries that rely on high-performance metal parts.

Summary

One of the major defects in a common 3D printing technique called laser powder bed fusion is the formation of keyhole pores. These pores or structural defects can compromise the performance of the printed parts. Many 3D printing machines have thermal imaging sensors that monitor what’s being built but can still miss the formation of pores. The only way to directly detect pores inside dense metal is by X-ray imaging, using highly intense beams such as those at the Advanced Photon Source, a Department of Energy Office of Science user facility.

Researchers correlated the X-ray images of the sample interior and the thermal images of the melt pool and discovered that the formation of a keyhole pore creates a distinct signal at the material’s surface that can be detected by thermal cameras. First, the researchers trained a machine learning model with X-ray images to predict the formation of pores using only thermal images. Then, they tested the model’s ability to decipher the complex thermal signals and predict pore generation in unlabeled samples. The researchers found the approach could detect the exact moment when a pore formed during the printing process on timescales of less than a millisecond.

Contact

Tao Sun

Northwestern University

taosun@northwestern.edu

Funding

This work was supported by the Department of Energy Office of Science and Honeywell Federal Manufacturing & Technologies. The research used resources at the Advanced Photon Source, a Department of Energy Office of Science user facility operated by Argonne National Laboratory.

Publications

Ren, Z., et al., Machine learning–aided real-time detection of keyhole pore generation in laser powder bed fusion. Science 379, 89 (2023). [DOI: 10.1126/science.add4667]

Related Links

Researchers unveil new AI-driven method for improving additive manufacturing, Argonne National Laboratory

Machine Learning Approach Helps Hit 100% Prediction Rate, University of Virginia School of Engineering and Applied Science