National lab and BWX Technologies develop a new way to manufacture and qualify parts and materials for high-temperature reactor applications.

March 3, 2021

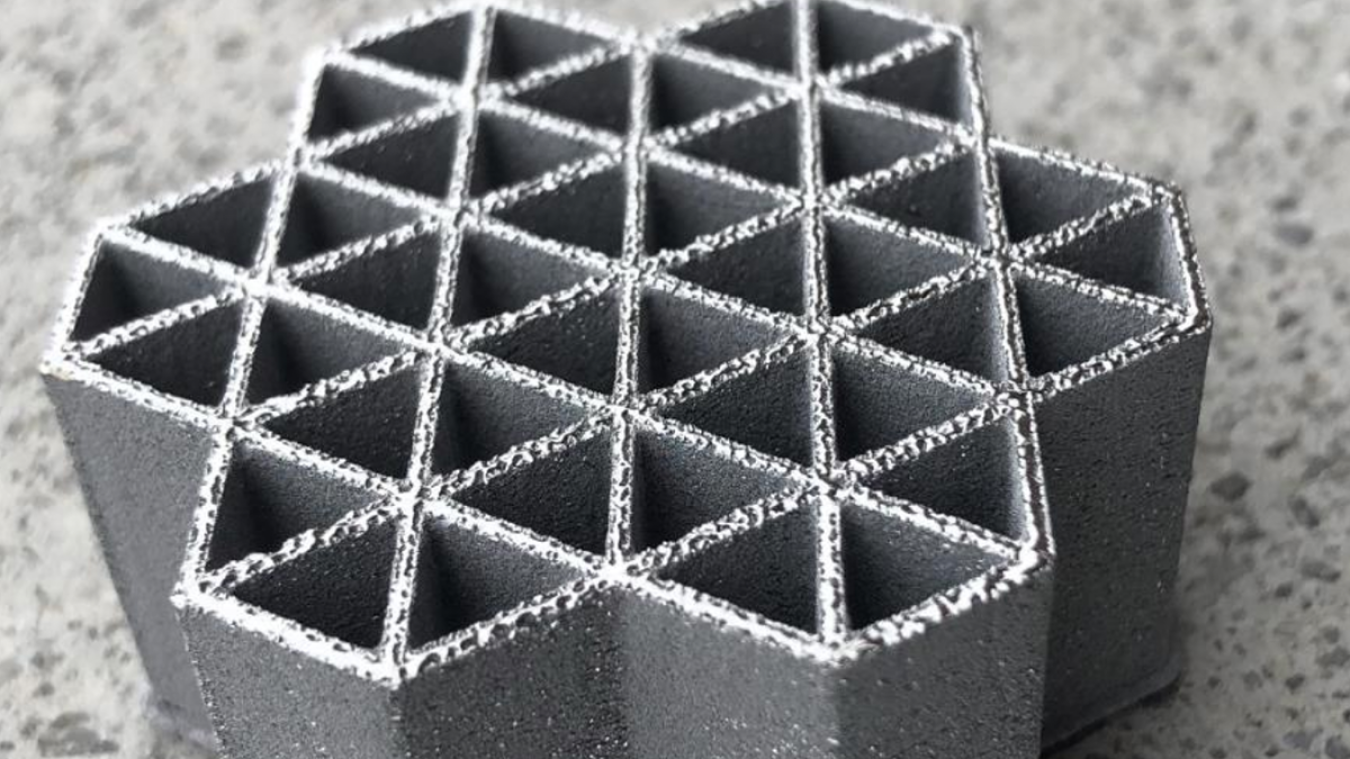

Component artifact geometry fabricated from molybdenum using electron beam melting. Completed molybdenum component.

Oak Ridge National Laboratory (ORNL) and BWX Technologies (BWXT) recently developed a new way to manufacture and qualify parts and materials for high-temperature reactor applications. The successful demonstration builds on recent advancements in additive manufacturing and could lead to the faster production of new reactor designs that would be more efficient and economical to produce.

Making the Impossible Possible

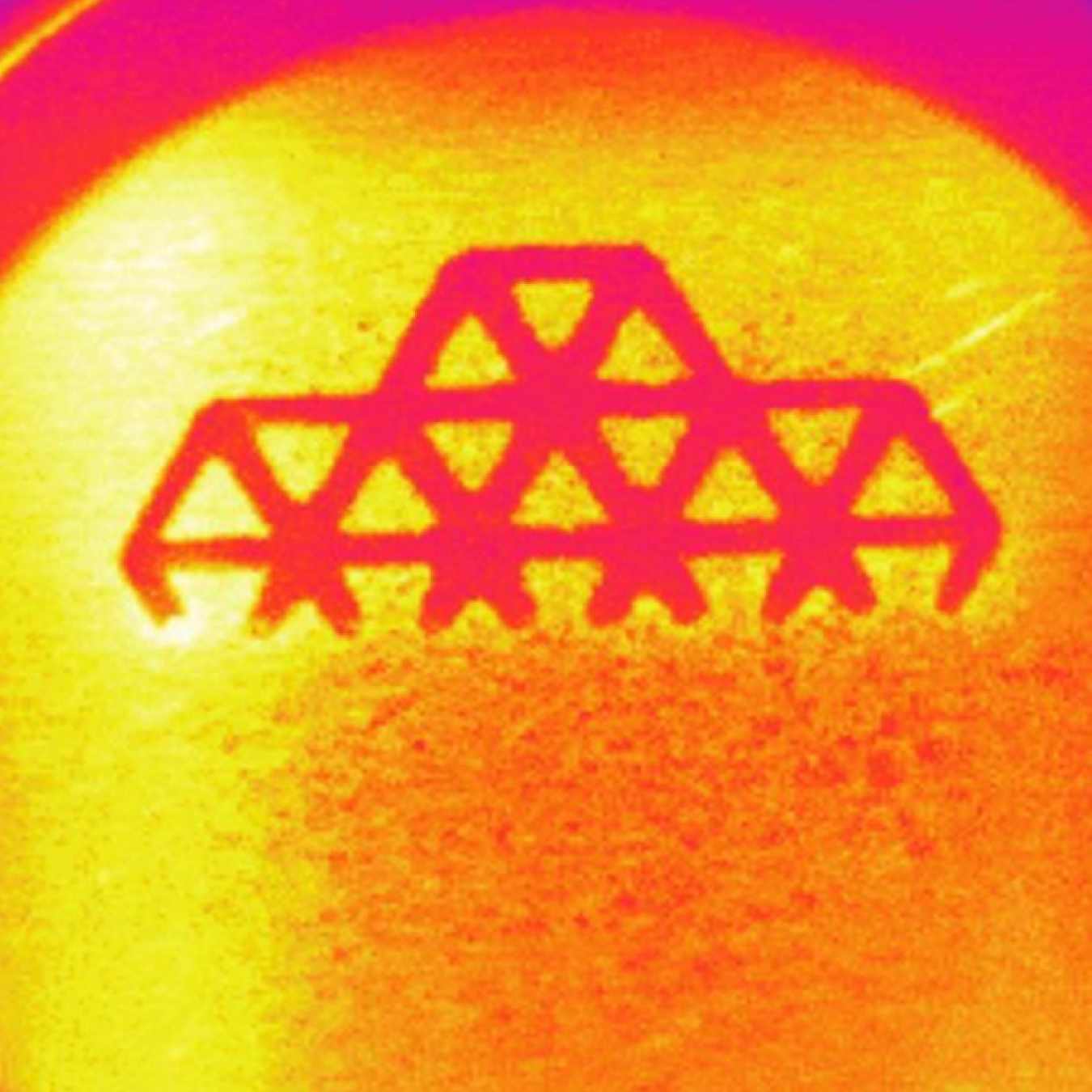

BWXT successfully 3D-printed core structural parts used in nuclear thermal propulsion system designs. The components were made from molybdenum—a refractory material that can be used in extreme temperatures. Working with ORNL researchers, BWXT used an electron beam melting system to print the intricate parts from molybdenum powder. Each layer, roughly a millimeter in length, was digitally captured during the process and used to qualify the components.

Component artifact geometry fabricated from molybdenum using electron beam melting. Component processing in-situ shown via infra-red imagery.

Refractory materials like molybdenum are extremely hard to fabricate given the extreme environments needed to create a part. The complex geometries created by the BWXT and ORNL team would have been nearly impossible to manufacture using conventional methods.

“Projects like these allow us to bring to bear our core expertise in the science of materials processing to deliver solutions specific to the demanding nature of nuclear energy applications,” said Michael Kirka, group leader for Deposition Science and Technology, Energy Science and Technology Directorate at ORNL.

The successful demonstration is the direct result of a nearly $10 million cost-share award from the Office of Nuclear Energy within the U.S. Department of Energy in 2018 to leverage the latest innovations in additive manufacturing and data science. Producing component-level qualification of materials, like molybdenum, will open the door for new advanced reactor designs that can yield higher efficiencies at a fraction of the cost.

“This is a great example of how a cost-share program can provide great benefits for the nuclear industry,” said Joe Miller, president for BWXT. “We were able to utilize BWXT’s design, data science and advanced manufacturing expertise along with ORNL’s facilities and subject matter experts to deliver a first-of-a-kind manufacturing process for extreme-temperature capable materials.”

Once fully tested and qualified, BWXT’s new process will be applied to the commercial market, greatly reducing overall development and fabrication costs of future nuclear reactors.

Learn more about this project.