Additive manufacturing could completely change the way we design, build and certify nuclear systems.

May 7, 2019Some people describe it as miniature welding. Others know it as 3D printing.

Whatever you decide to call it, it’s time to get familiar with additive manufacturing. It’s going to completely change the way we design, build and certify nuclear systems.

Additive manufacturing is a fairly new process of making physical, three-dimensional objects from a computer design file.

This allows you to create complex shapes, layer by layer, that can be rapidly prototyped and tested to reduce the time and money it takes to develop a product.

Our national labs are already at the center of this innovation—successfully producing cars, wind turbine blade molds and even live cells through this emerging technology.

Nuclear applications could be next, opening up four big opportunities for the industry to quickly deploy technologies at a fraction of the cost.

Greater Design Flexibility

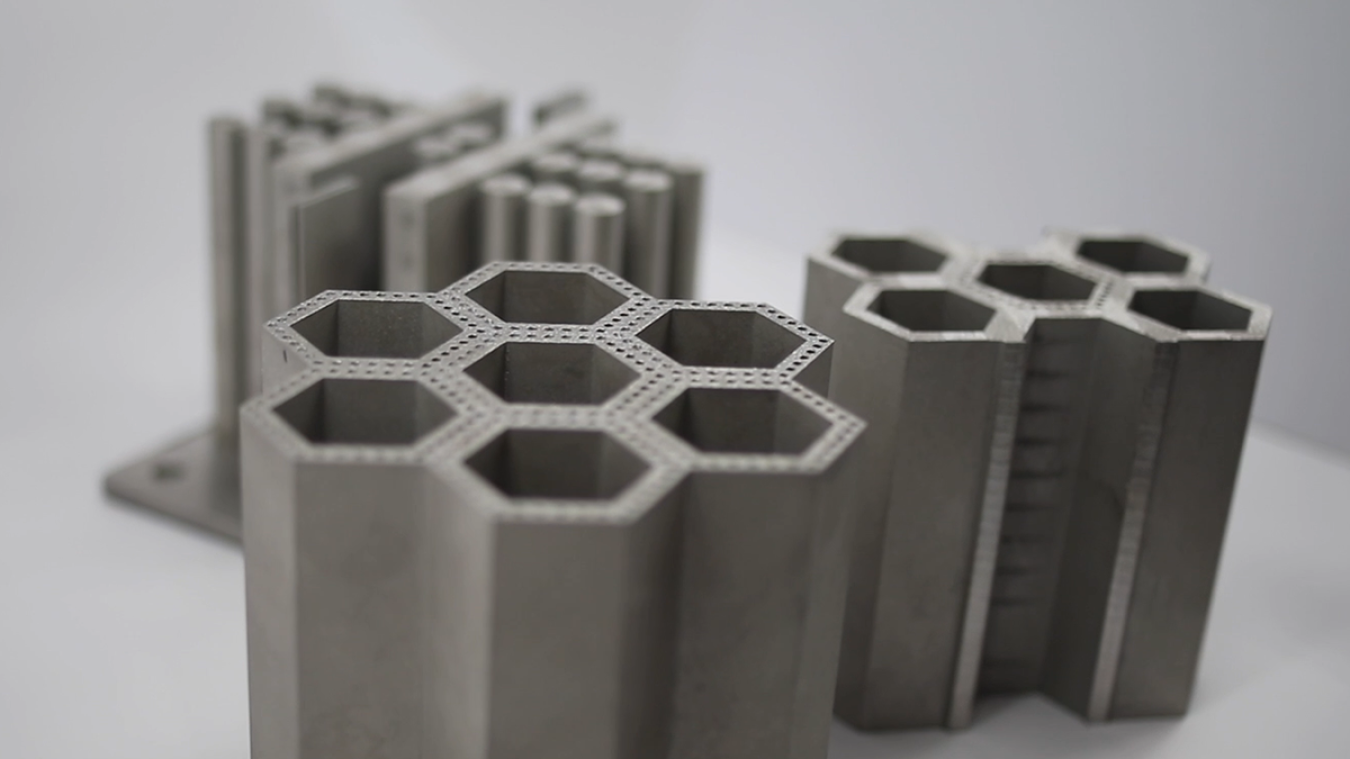

Through the use of additive manufacturing, the nuclear industry will no longer be burdened by traditional, decades-old manufacturing techniques. The flexibility in 3D printing allows designers to place materials where needed or pursue systems outside traditional structures.

Advancement of New Materials

Nuclear energy continues to rely on materials developed nearly 50 years ago. With the integration of advanced manufacturing and computational sciences, researchers can quickly analyze and confirm materials for nuclear environments significantly easier.

Certifying and Qualifying New Parts

In building a part or system layer-by-layer, enormous amounts of data are collected and analyzed. This shortens the time needed to deploy it because of the understanding of how it will perform.

Embedding Sensors for Real-time Monitoring

Through the use of advanced control systems and integrated sensors that are integrated into parts or the entire system, operators have real-time information on performance that allows for preventive maintenance and possibly autonomous operations.

Learn more about advanced methods for manufacturing and the work that is being supported by the Office of Nuclear Energy.