In 2018, the U.S. Department of Energy (DOE) Sustainability Performance Office recognized ten teams and two individuals representing DOE sites and national laboratories. The winners were recognized for their commitment to sustainability and their contributions to energy efficiency, waste reduction, water efficiency, and recycling.

Below find the descriptions of the 2018 DOE Sustainability Award winners organized by award category.

Outstanding Sustainability Programs or Projects are sustainable projects or programs that reduce costs and increase efficiency.

Nevada National Security Site's Fleet, Fuel and Equipment Services Department Project Team (Aaron Barrie, Patrice Claxton, Ricky Medina, Brent Nordin, Michael Smith, James Stedeford, Jody Taylor, Doug Trone, Jason Vandeman, and Robert Young)

Nevada National Security Site’s Fleet, Fuel and Equipment Services Department Project

Nevada National Security Site’s (NNSS) “Fleet, Fuel and Equipment Services Department” project won an Outstanding Sustainability Program/Project award. NNSS created a pilot program that tested the effects of using R100 renewable diesel versus B20 biodiesel in their fleet. This pilot program found that both vehicles and equipment show a longer runtime when using R100, while the same assets experience frequent component failure when running on B20. B20 solidifies in temperatures below freezing, and, unlike B20, R100 has no separation and does not require disassembly of equipment fuel systems.

Bonneville Power Administration's Xeriscaping Pilot Project Team (Jennifer Bachman, Carol Krohn, Jennifer Williams, and Jose Aguilar)

Bonneville Power Administration's Xeriscaping Pilot Projects

Bonneville Power Administration (BPA) won for their “Xeriscaping Pilot Projects.” BPA completed three xeriscaping pilot projects at three of its substations, which saved approximately 2 million gallons of water in a single year. The projects eliminated the need for landscaping, reduced water consumption from irrigation, and increased the ability to manage stormwater runoff. BPA is implementing six additional xeriscaping projects and will incorporate lessons learned from these outstanding pilot projects.

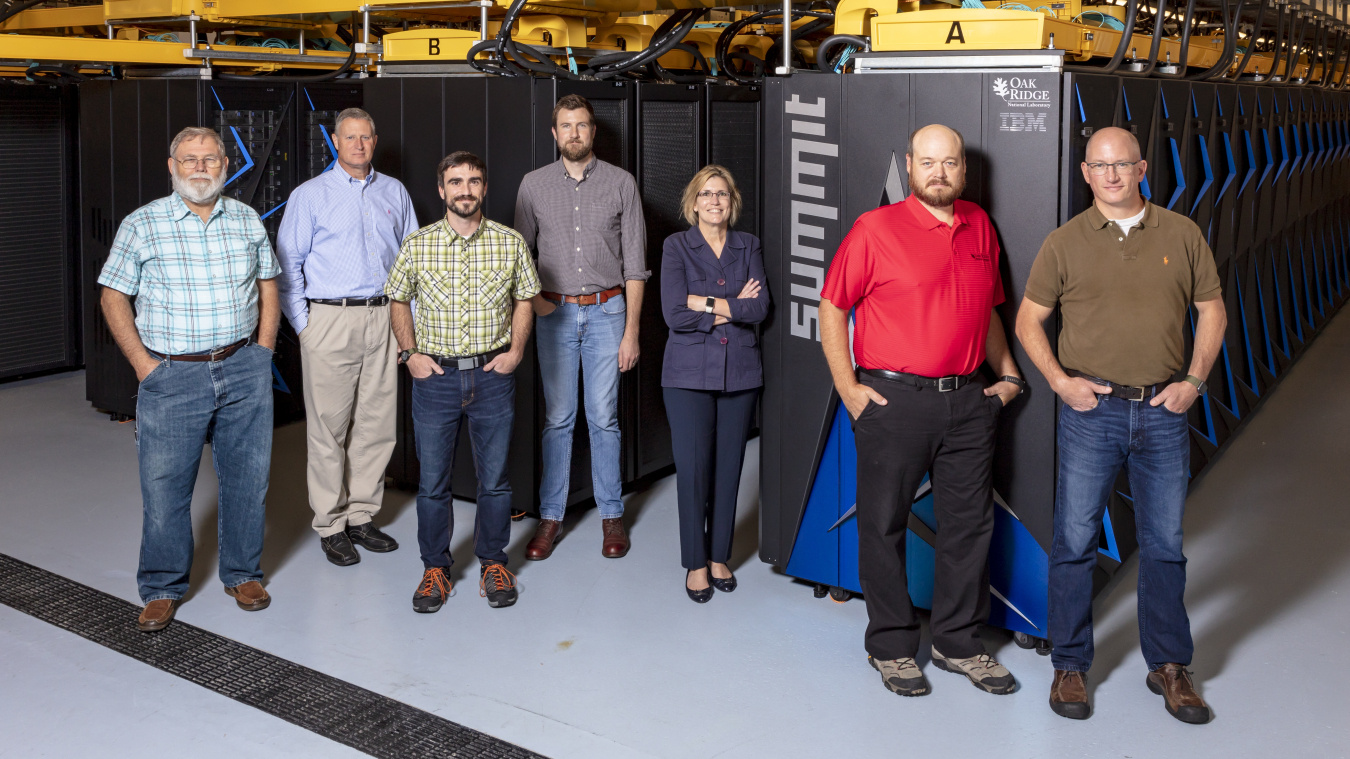

Oak Ridge National Laboratory’s High Performance Computing Summit Facility – Designed for Success Project Team (Rick Griffin, James Rogers, David Grant, Bryce Hudey, Melissa Lapsa, James Abston, and Bart Hammontree)

Oak Ridge National Laboratory’s High Performance Computing (HPC) Summit Facility – Designed for Success Project

Oak Ridge National Laboratory’s (ORNL) “High Performance Computing (HPC) Summit Facility – Designed for Success” project won an honorable mention for Outstanding Sustainability Program/Project. In 2017, ORNL completed the build-out of the infrastructure for their Titan supercomputer to be replaced with Summit—a new high performance computing system. The Summit system is capable of peak performance of 200,000 trillion calculations per second—or 200 petaflops. ORNL relied on a more efficient design, which resulted in $3.7 million in construction cost savings by replacing the conventional chilled water system with a warm water system.

Strategic Partnerships for Sustainability are partnerships between sites or with other organizations that contribute positively to site sustainability.

Y-12 National Security Complex’s Building Partnerships for a Sustainable Future Project Team (Gene Sievers, Tim Hutson, Nathan Wallace, Bud Slaven, Jason Phillips, Don Peters, Joe Duncan, Halen Philpot, and Brian Whitus)

Y-12 National Security Complex’s Building Partnerships for a Sustainable Future Project

Y-12 National Security Complex’s (Y-12) “Building Partnerships for a Sustainable Future” project won a Strategic Partnerships for Sustainability award. Y-12’s Construction Support Building is the first permanent structure of the Uranium Processing Facility for enriched uranium operations and the first LEED Gold building at Y-12. The strategic partnership between the Uranium Processing Facility Project Office, U.S. Army Corps of Engineers Nashville District, Consolidated Nuclear Security for the Facility, and Y-12 site personnel ensured that the Construction Support Building was completed on-time and $5 million under budget.

Argonne National Laboratory's Smart Energy Plaza and Electric Vehicle Charging Program

Argonne National Laboratory's Smart Energy Plaza and Electric Vehicle Charging Program

Argonne National Laboratory (ANL) won a Strategic Partnerships for Sustainability award for its “Smart Energy Plaza and Electric Vehicle Charging Program.” Researchers from Argonne's Center for Transportation Research and Argonne's sustainability program worked together on the Smart Energy Plaza and Electric Vehicle Charging Program, which renovated an on-site gasoline station for use as a smart energy plaza. The plaza includes charging stations for electric vehicles, solar canopies, and space for a research facility. The program increased its electric vehicle charging stations by 46% and increased Argonne’s on-site solar energy production by 73%.

LLNL and SNL Project Team (Melissa Sale, Neelam Murthi, Heather Ottaway, Janet Harris, Heather Stratton, Angelina Hansen, Joy Macpherson, Dee Dee Dicker, Colin Yamaoka, Tristan Mahyera, Morgan Edwinson, Phil Arzino, and Gina Madison)

Lawrence Livermore National Laboratory and Sandia National Laboratories (SNL)’ Forge Ahead Towards Collaborative Sustainability Project

Lawrence Livermore National Laboratory (LLNL) and Sandia National Laboratories’ “Forge Ahead Towards Collaborative Sustainability” project won an honorable mention for Strategic Partnerships for Sustainability. The cornerstone of collaboration between LLNL and Sandia is the dedicated event pad constructed to provide a permanent location for events that promote community engagement, employee health, and environmental sustainability. Due to their close proximity, the two sites are able to meet monthly to discuss DOE sustainability goals, such as waste management and sustainable acquisition, as well as how each partner can improve site performance. Some of their 2017 projects included an Earth Day celebration, a Bike to Work Day, and a Share Your Ride event.

Innovative Approach to Sustainability awards are original or inventive ideas or methods and technologies that improve site sustainability and can be applied across DOE.

Idaho National Laboratory’s Motor Coach Solar HVAC Proof of Concept Project Team (Jeff Brown, Michael Perez, Bill Ziegler, Colin Letham, and Ira Pray)

Idaho National Laboratory’s Motor Coach Solar HVAC Proof of Concept Project

Idaho National Laboratory’s (INL) “Motor Coach Solar HVAC Proof of Concept” project won an Innovative Approach to Sustainability award. INL partnered with Motor Coach Industries and Bergstrom Inc. to design a solar powered air conditioning system specifically for motor coaches to reduce fossil fuel consumption. By pre-cooling vehicles using solar power, INL was able to reduce its consumption of petroleum fuels and its operating costs. INL projects an annual savings of 10,000 gallons of diesel fuel per year, avoiding 87 metric tons of carbon dioxide emissions annually.

Lawrence Livermore National Laboratory's Fleet of Sedans Goes Electric Project Team (Jessica Copeman, Hanif Nassor-Covington, Al Moser, Stu Jossey, and Scott Chau)

Lawrence Livermore National Laboratory's Fleet of Sedans Goes Electric Project

Lawrence Livermore National Laboratory (LLNL) won an Innovative Approach to Sustainability award for its “Fleet of Sedans Goes Electric” project. LLNL expanded its electric vehicle charging infrastructure by building multiple Level II charging stations for its growing fleet of electric vehicles. Level II charging stations charge vehicles in half of the time it takes for a Level I station. New portable Level II chargers at LLNL track the amount of avoided greenhouse gas emissions and pounds of carbon dioxide saved. This additional infrastructure provides more employees the opportunity to charge electric vehicles at work and reduces greenhouse gas emissions associated with employee commuting.

Los Alamos National Laboratory's Biobased Lubricant Used in Metal Cutting Operations Identified as Waste Diversion Strategy Project Machinists (Thomas Meredith and Thomas Chavez)

Los Alamos National Laboratory's Biobased Lubricant Used in Metal Cutting Operations Identified as Waste Diversion Strategy Project

Los Alamos National Laboratory (LANL) won an honorable mention for Innovative Approach to Sustainability for its “Biobased Lubricant Used in Metal Cutting Operations Identified as Waste Diversion Strategy” project. Los Alamos National Laboratory’s Maintenance & Site Services welding shop replaced traditional oil-based lubricants with a bio-based lubricant for use on metal-cutting machinery. The new lubricant is 100 percent biodegradable, non-toxic, and formulated from water and renewable plant-based oils. LANL transitioned from using 55 gallons of oil to just one gallon of bio-based lubricant during 2017. The lab is saving approximately $5,000 per year in spent oil disposal costs.

Sustainability Champions are individuals who make an effort to advance sustainability goals relating to green buildings, sustainable acquisition, water, etc.

Patricia (Pat) Gallagher from Los Alamos National Laboratory

Patricia (Pat) Gallagher from Los Alamos National Laboratory is a Sustainability Champion

SPO made a posthumous award to Patricia (Pat) Gallagher from Los Alamos National Laboratory (LANL) for Sustainability Champion. Although Pat is no longer with us, for over 20 years, she integrated sustainability concepts into various LANL programs and initiatives. Pat led implementation of the ISO 14001 Environmental Management System, created the LANL Pollution Prevention awards program, and ensured engineering staff were trained in green buildings, which contributed to the incorporation of sustainability into engineering and building standards. Pat led by example and impacted DOE’s sustainability goals.

Frank McHenry from Y-12 National Security Complex

Frank McHenry from Y-12 National Security Complex is a Sustainability Champion

Frank McHenry from Y-12 National Security Complex (Y-12) won a Sustainability Champion award. Frank successfully implemented energy savings performance contracts (ESPCs) in coordination with the Y-12 Maintenance & Operations contractor. ESPCs are contracts that also come with financing, and can be used to complete infrastructure projects. Frank was committed to the success of multiple ESPC projects, often putting in overtime to ensure feedback was received from users and that reported results were accurate. Combined, these ESPC projects have guaranteed annual cost savings of almost $8 million and will save 240 million gallons of water.

Sandia National Laboratories’ Bicycle Commuter Group Makes Strides Project

Sandia National Laboratories’ Bicycle Commuter Group Makes Strides Project

Sandia National Laboratories’ “Bicycle Commuter Group Makes Strides” project won an honorable mention award for Sustainability Champion. The Sandia Bike Commuter Group contributed to the prevention of 1,208 mtCO2e of greenhouse gas emissions, more than 6 million miles from being driven, and more than 275,000 gallons of gas from being burned at Sandia. This has resulted in less traffic congestion, more traffic and bike related safety features, and a healthier environment.