The Carbon Capture Program’s rationale for funding CO2 capture technologies is to offset risk that private industry will not absorb. This is balanced by cost share requirements—the rationale being that if private industry recognizes potential value, and if the technology development risk is offset, they should be willing to make investments in R&D expenditures.

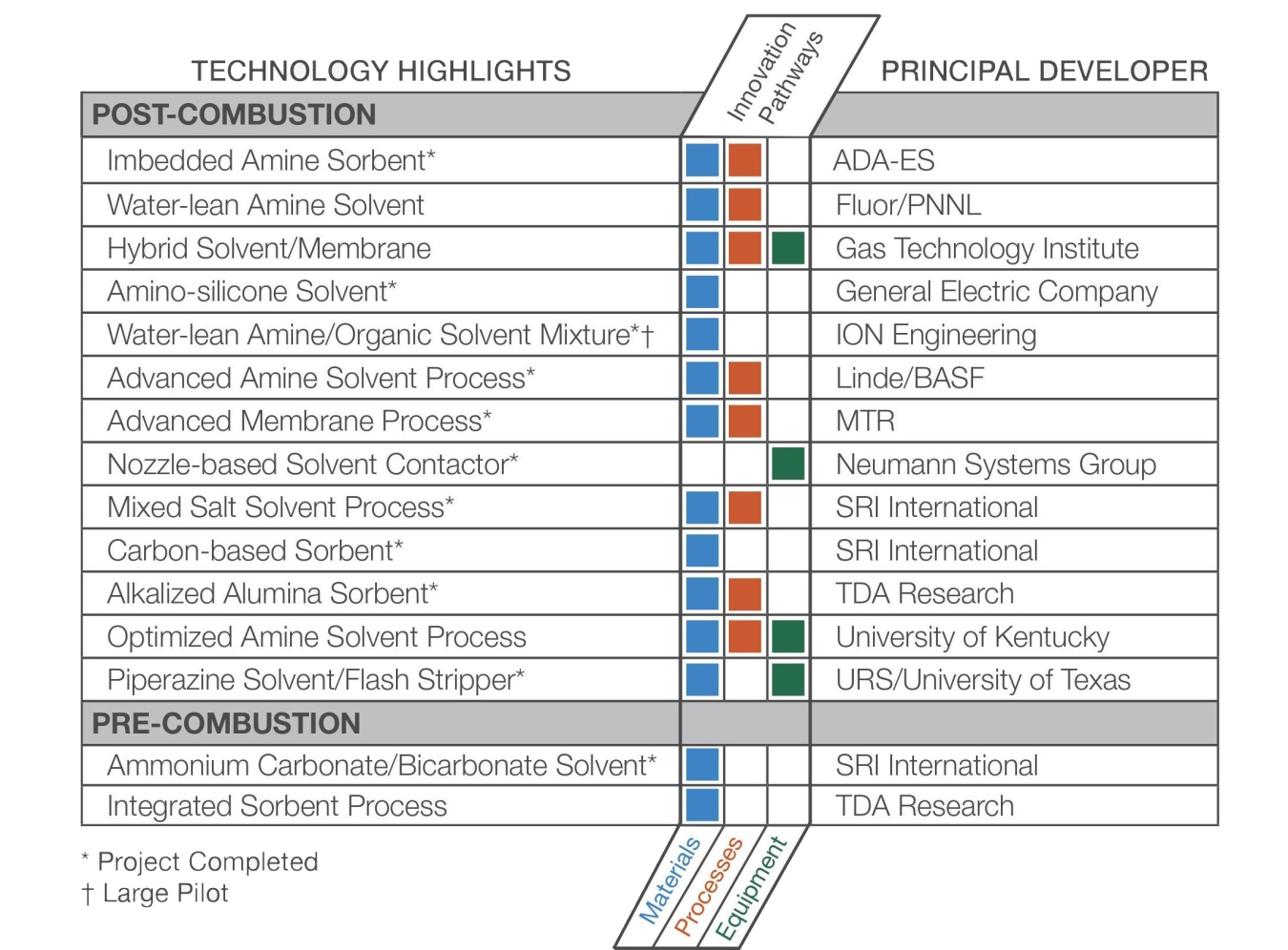

The technology development process typically follows a series of steps: laboratory/bench-scale testing of promising concepts followed by advancement to successively higher Technology Readiness Levels. There is insufficient information generated at the laboratory/bench scale to confidently predict eventual commercial success. Thus, to further de-risk industrial investment, the Carbon Capture Program adopts a down-selection process that graduates technologies from a large portfolio of laboratory/bench-scale projects to a small portfolio of engineering scale projects. Looking specifically at 2nd-generation technologies, the Carbon Capture Program has advanced 15 approaches to engineering scale testing ranging from 0.5 – 12.5 MW, as illustrated below.

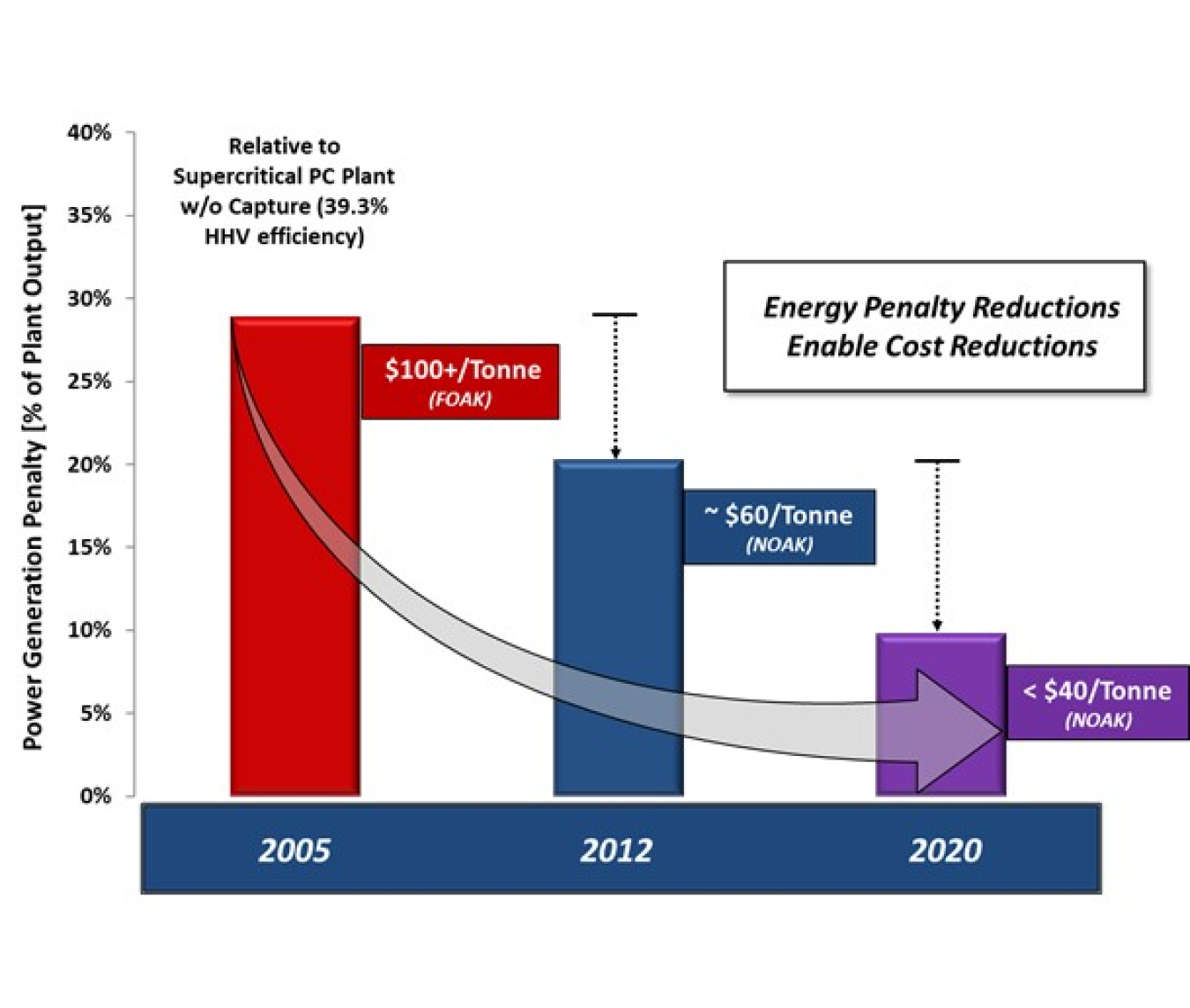

The efficacy of this approach is illustrated by the success of the program to date. Considerable cost reductions have already been realized over the life of the Carbon Capture Program, particularly costs arising from the energy penalty from CO2 capture in power generation, as illustrated below. Costs have decreased from over $100/tonne in 2005 for 1st-generation technologies, and the cost for 2nd-generation technologies is now approaching $40/tonne.

One of the key elements in promoting the success of 2nd-generation capture technologies has been the ability to test systems at both laboratory/bench and engineering scales at the National Carbon Capture Center (NCCC). The NCCC, which is funded by DOE/NETL and operated by Southern Company Services, gives technology developers a test facility to accelerate the commercialization of their technologies. The NCCC receives actual flue gas from an existing coal-fired power plant and provides it for post-combustion testing.

Additionally, the NCCC is adding a natural gas boiler to allow testing on natural gas flue gas. These gas streams allow for development at scales ranging from 0.1–1.0 MWe equivalent. To date, more than 100,000 hours of technology testing on approximately 60 technologies has been conducted at NCCC—contributing to cost reductions of approximately one-third compared to previously existing technologies. More than half of the 2nd-generation technologies that have advanced through the Carbon Capture Program development process to engineering scale have undergone testing at NCCC at some point.