EM Office of River Protection (ORP) tank operations contractor Washington River Protection Solutions (WRPS) is ready to begin assembling additional melters to support the Direct-Feed Low-Activity Waste (DFLAW) Program at the Hanford Site.

EM crews at the Hanford Site’s Waste Treatment and Immobilization Plant (WTP) recently held an employee safety expo highlighting information, equipment, supplies and success stories promoting the health and safety of workers both at home and the jobsite.

The Hanford Site recently hosted National Weather Service (NWS) Western Region Director Grant A. Cooper, who toured the site’s emergency operations center and meteorological station.

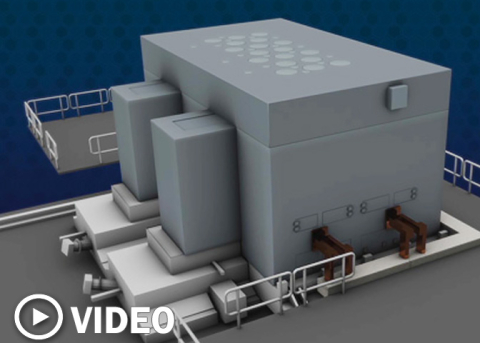

Crews at the Hanford Site have begun heating up the world’s largest melter that will transform radioactive and chemical tank waste currently stored in underground tanks into a vitrified glass form safe for disposal.

Workers with EM Office of River Protection (ORP) tank operations contractor Washington River Protection Solutions (WRPS) are “going green” with new battery-powered electric generators on the Hanford Site.

EM Richland Operations Office (RL) contractor Hanford Mission Integration Solutions (HMIS) recently held a formal ceremony for the Hanford Fire Department.

EM contractor Hanford Laboratory Management and Integration (HLMI), which runs the Hanford Site’s 222-S Laboratory, received the Voluntary Protection Program (VPP) Superior Star award from DOE at a recent national conference in Washington, D.C.

EM Senior Advisor William “Ike” White praised recent progress in EM’s cleanup work and laid out a roadmap of future success as he kicked off the first full day of the annual National Cleanup Workshop in Arlington, Virginia on Sept. 22.

Eight managers leading cleanup at EM sites across the DOE complex highlighted successes and shared challenges over the past year during a roundtable discussion at the National Cleanup Workshop.

A National Cleanup Workshop panel comprised of federal and contractor leaders and community stakeholders from across the DOE complex shared insights into succession planning to help develop EM’s future workforce.