RSS

U.S. Department of Energy (DOE) Office of Environmental Management (EM) Principal Deputy Assistant Secretary Jeff Avery recently visited North Augusta, S.C. to provide the keynote address for the Energy, Technology & Environmental Business Association’s (ETEBA) Savannah River Federal Business Opportunities Forum.

Drones are undergoing testing to support emergency response at the U.S. Department of Energy Office of Environmental Management’s (EM) Paducah Site.

The Hanford Site’s 222-S Laboratory, operated by contractor Navarro-ATL, is upgrading the specialized equipment personnel use to safely handle and analyze samples to support cleanup operations across the site.

U.S. Department of Energy Office of Environmental Management crews recently demolished another steel-framed, fabric-covered building at the Radioactive Waste Management Complex’s Subsurface Disposal Area at the Idaho National Laboratory Site. Just three buildings remain on the 97-acre Cold War-era landfill, following removal of this former waste storage building.

The Oak Ridge Office of Environmental Management (OREM) and contractor UCOR hosted more than 50 guests on a guided tour to observe progress on the construction of the Environmental Management Disposal Facility (EMDF).

Control room personnel monitor systems at the Hanford Site’s Waste Treatment and Immobilization Plant after recently adding the first batch of “tuning feed” to one of the plant’s large melters.

The International Organization for Standardization (ISO) has recertified the West Valley Demonstration Project’s Environmental Management System, a management practice that allows organizations to conduct work in a systematic manner to minimize impacts of operations on the environment.

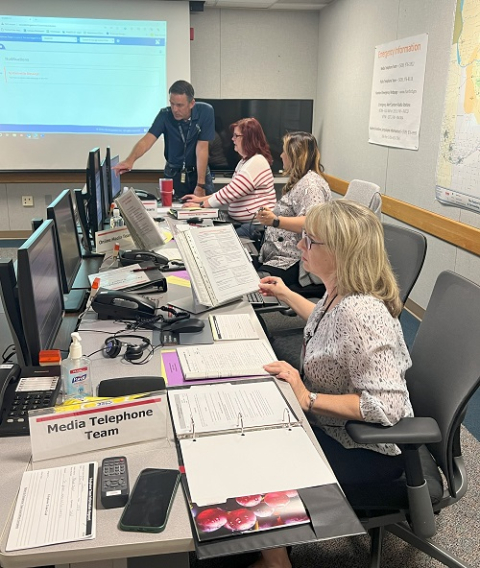

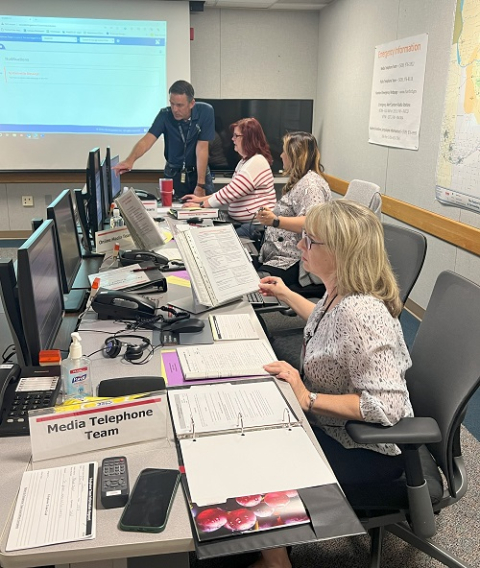

Crews with U.S. Department of Energy Office of Environmental Management (EM) contractor Hanford Mission Integration Solutions (HMIS) designed a unique and challenging scenario to test the effectiveness of emergency response during the Hanford Site’s recent Annual Field Exercise.

EM is draining the last large concrete basin at the Hanford Site.

Portsmouth Site crews relied on detailed planning, collaboration and teamwork to successfully complete the characterization activities in the X-333 Process Building, which is slated for demolition early next year.