EM’s vitrification plant at Savannah River Site (SRS) is undergoing a significant process improvement.

Office of Environmental Management

May 24, 2022

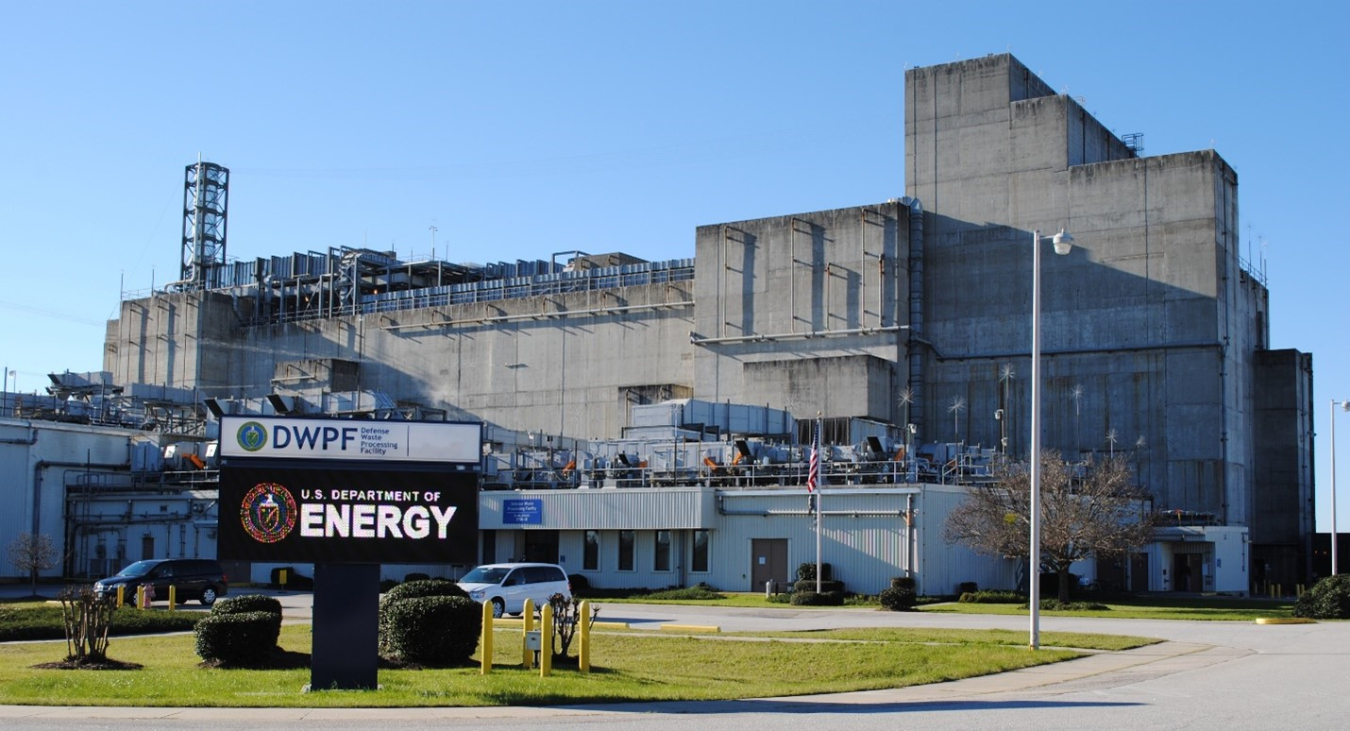

AIKEN, S.C. – EM’s vitrification plant at Savannah River Site (SRS) is undergoing a significant process improvement.

The Defense Waste Processing Facility (DWPF) enters an outage this month to begin the replacement of formic acid with glycolic acid in the facility’s vitrification process. Glycolic acid will allow for safer processing of high-activity radioactive waste at DWPF, leading to more efficient conversion of waste into glass. The transition to glycolic acid is expected to be completed by October 2022.

The current use of formic acid results in generation of hydrogen and produces ammonia as the acid reacts at elevated temperatures. Glycolic acid significantly reduces these off-gas hazards while providing chemical stability for the process.

This change is another step to ensure the Salt Waste Processing Facility (SWPF) can operate at high production rates since DWPF will be able to treat greater quantities of waste due to the stability of the process.

SRS liquid waste contractor Savannah River Mission Completion (SRMC) operates DWPF and SWPF for EM.

Savannah River National Laboratory performed testing that contributed to the selection of glycolic acid as a replacement for formic acid. The replacement of formic acid with glycolic acid was studied for 10 years before it was put into use, according to Jim Folk, DOE-Savannah River assistant manager for waste disposition.

“Extensive laboratory testing showed us that glycolic acid enables DWPF to treat more waste, removing curies from SRS waste tanks at a faster rate,” Folk said. “Safely removing greater volumes of liquid waste continues to reduce the risk this waste poses.”

Wyatt Clark, SRMC chief operations officer, said the use of glycolic acid is a significant innovation for the overall waste treatment process.

“We expect glycolic acid to improve the overall efficiency of waste processing inside DWPF,” Clark said. “Removing formic acid will allow us to process more waste. The overall impact is more efficient processing in an environment that is even safer than before, making this a win-win for the SRS Liquid Waste Program and our employees.”

The change to glycolic acid means that all major SRS liquid waste facilities will also be paused since the facilities are integrated. However, during this planned outage, preventive and corrective maintenance work will be performed in SRS liquid waste facilities. Performing this maintenance work now takes advantage of the pause and will make the entire liquid waste system more reliable and more robust when operations resume.

During the outage, the Saltstone Disposal Units construction will continue, as will any work not connected to the change to glycolic acid. Those units are where the saltstone grout resulting from waste processing solidifies into a nonhazardous, solid low-level waste form.

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.