Preparations to retrieve radioactive and chemical waste from another group of large underground tanks at the Hanford Site are gaining momentum.

Office of Environmental Management

November 14, 2023

RICHLAND, Wash. – Preparations to retrieve radioactive and chemical waste from another group of large underground tanks at the Hanford Site are gaining momentum.

Workers with EM Office of River Protection contractor Washington River Protection Solutions (WRPS) recently drilled an opening through the thick concrete top of Tank A-106 to provide access for waste retrieval equipment.

Within the next year, they will begin retrieving waste from six older single-shell tanks in the A Tank Farm, one of 18 farms at Hanford that received waste generated during plutonium production. Crews will transfer the waste to a newer double-shell tank for safe storage until it is treated.

Watch workers with Hanford Site tank operations contractor Washington River Protection Solutions drill a hole into the dome of an A Farm tank to install retrieval equipment — a high-hazard operation that has only been done three times in the last 15 years at Hanford.

A remote-controlled camera captured this picture inside underground waste tank A-106 after workers drilled through the concrete dome to create a new opening for waste retrieval operations.

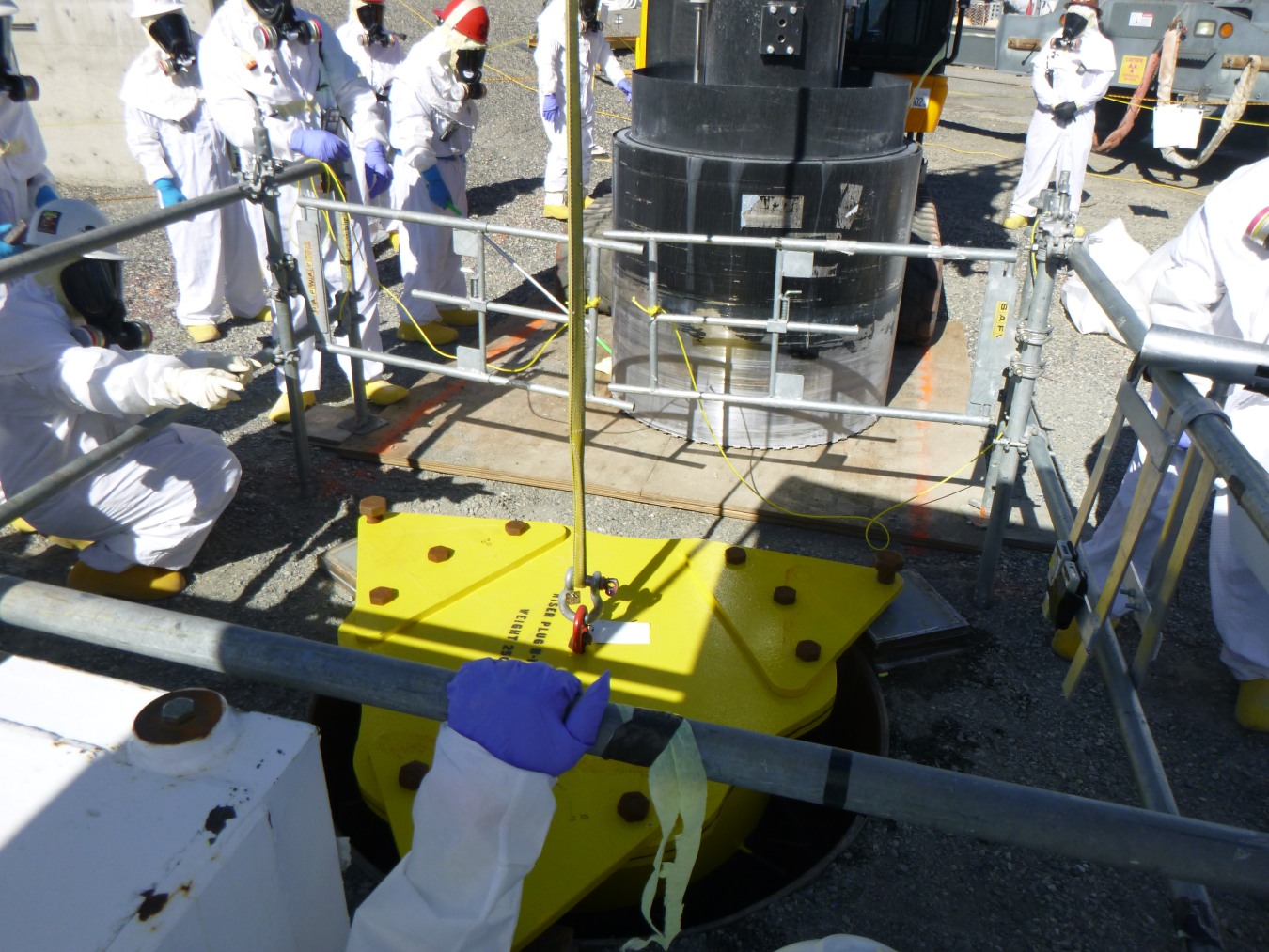

Workers used a large drill to make the opening and installed a pipe, called a riser, that will accommodate new retrieval equipment. This task has only been done three times in the last 15 years at Hanford, and before drilling, crews trained on and tested equipment at Hanford’s Cold Test Facility.

“Time spent perfecting skills in a lower-risk environment like a mock-up is invaluable,” said Jim Greene, EM Tank Farms Program Division program manager. “Making progress on our risk-reduction mission requires developing, testing and using specialized tools and techniques. This way when workers go into the field, they can do the job safely and more efficiently.”

Crews also recently installed a pump in Tank A-101, the first tank in A Farm scheduled for retrieval. Soon workers will install two more large pieces of equipment in the tank to break down waste during retrieval operations.

“We have outstanding employees who own their work and maintain a culture of teamwork,” said Peggy Hamilton, WRPS Single-Shell Tank Retrievals manager. “They watch out for their fellow workers while doing this important work to protect site personnel, local communities and the environment.”

Waste retrieval in A Farm is scheduled to start in the summer of 2024. The A Farm tanks were built in the mid-1950s, and store waste generated by plutonium processing at the nearby Plutonium Uranium Extraction Plant during the Cold War era.

Hanford’s C Farm, with 16 underground tanks, was the first tank farm to be completely retrieved, five years ago. Retrieval of one tank in the S Farm was completed in 2007. Workers are retrieving waste from the last of the four tanks in the AX Farm.

-Contributor: Kristin M. Kraemer

To receive the latest news and updates about the Office of Environment Management, submit your e-mail address.