The EM and NNSA Los Alamos field offices and contractor Los Alamos National Security, LLC have finished treating the remediated nitrate salts at LANL.

Office of Environmental Management

November 7, 2017

LOS ALAMOS, N.M. – The EM and National Nuclear Security Administration Los Alamos field offices and contractor Los Alamos National Security, LLC have finished treating the remediated nitrate salts (RNS) at Los Alamos National Laboratory (LANL).

“Safe and successful completion of the RNS treatment is due to effective partnering between multiple organizations and demonstrates the way DOE strives to conduct operations in a high hazard environment,” EM Los Alamos Field Office Manager Doug Hintze said.

EM Safety, Security and Quality Assurance Deputy Assistant Secretary Jim Hutton noted that workers upheld high standards in their work, pausing when necessary to address issues, and management supported that constructive behavior.

“As a result, the workers identified process improvements that increased efficiency — and identified minor problems early — and management supported correcting those problems,” Hutton said. “This accelerated the safe completion of the RNS treatment.”

Treatment at a Glance

- The RNS drums contained an incompatible combination of nitrate salt waste mixed with an organic absorbent. The drums needed to be treated to allow safe disposition of the waste at the Waste Isolation Pilot Plant (WIPP).

- Treatment of the 60 RNS drums stored at LANL began in May 2017.

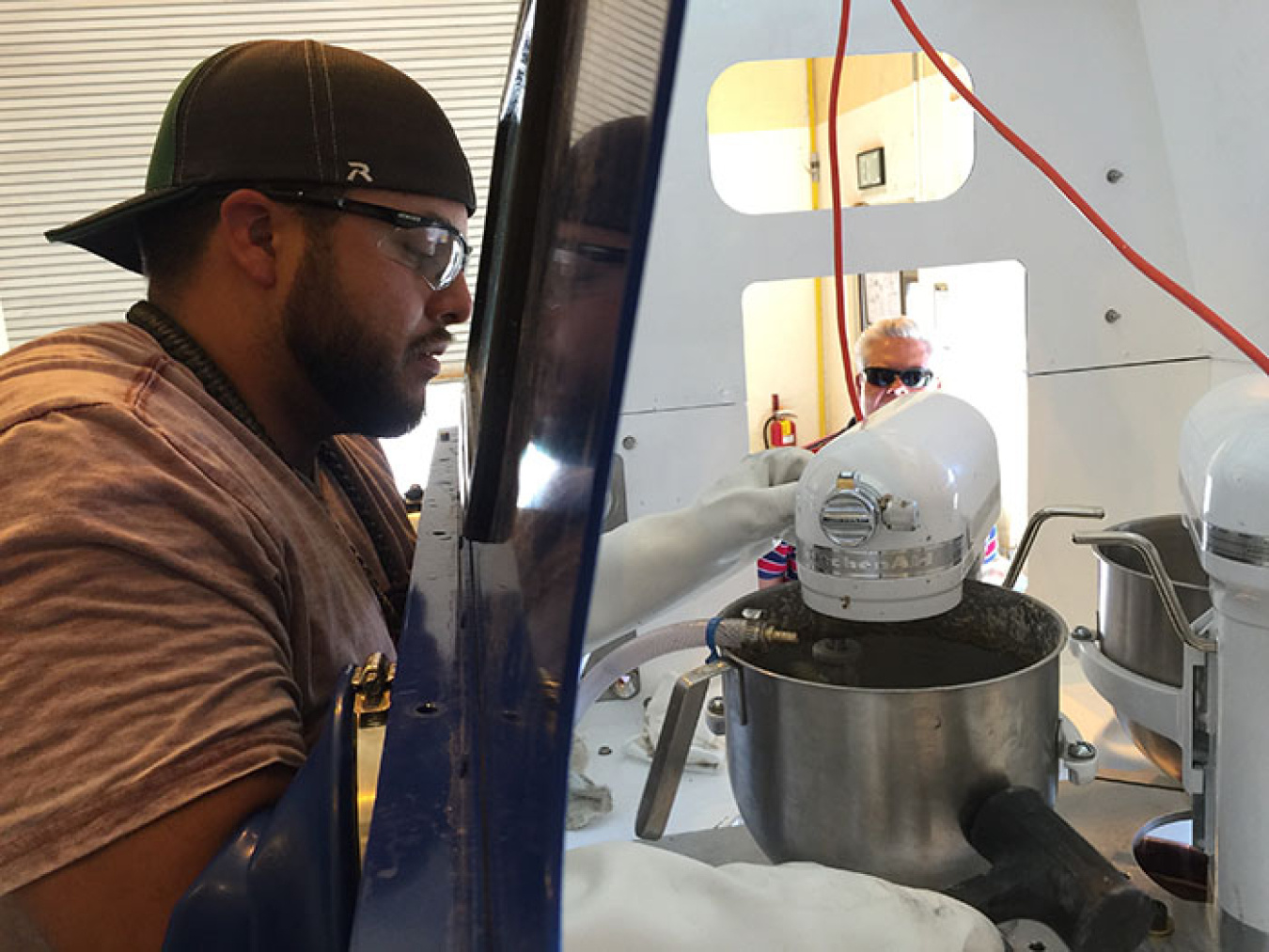

- The treatment involved removing the RNS waste from drums and mixing it with water and zeolite, an inert material, to render the waste non-reactive.

- The risk associated with the RNS waste stored at LANL has been removed.

- The treated RNS waste was repackaged into new drums, which are safely stored at LANL. They will undergo certification prior to being shipped to WIPP for disposal.