The U.S. Testing Expertise and Access for Marine Energy Research (TEAMER) program helped E-Wave Technologies develop a wave energy converter from concept to test-validated device.

Hydropower and Hydrokinetic Office

August 13, 2024This is the first in a series of articles highlighting projects advanced through the U.S. Testing Expertise and Access for Marine Energy Research (TEAMER) program. TEAMER provides marine energy technology researchers and developers with streamlined access to U.S.-based test facilities and world-class technical expertise. Since TEAMER launched in 2020, the program has supported more than 150 marine energy physical testing and numerical modeling projects with more than $16 million in technical support.

Testing new marine energy devices is often difficult and time consuming. Researchers and developers must contend with lengthy permitting processes, limited testing infrastructure, and expensive environmental monitoring. This was an empty link: This can make testing, deploying, and optimizing technologies challenging to do in a timely and cost-effective manner. But as the country transitions to a 100% clean energy economy, marine energy has tremendous potential as one of the last untapped renewable energy sources and testing is required to unlock it.

That’s why, in 2020, the U.S. Department of Energy (DOE) launched the TEAMER program. Sponsored by the U.S. Department of Energy’s Water Power Technologies Office (WPTO) and directed by the Pacific Ocean Energy Trust, TEAMER gives developers the opportunity to partner with academic institutions, national and private research laboratories, and private companies in the Facility Network to test and refine new marine energy devices.

This opportunity for testing is essential for companies like E-Wave Technologies. Over the course of five rounds of technical support, TEAMER supplemented funding from the Small Business Technology Transfer (STTR) program and helped E-Wave develop a wave energy converter (WEC) from concept to test-validated device. The E-Wave WEC is designed to power offshore aquaculture farms with clean and affordable energy, and E-Wave is now advancing it toward commercialization.

Solving a Logistical and Financial Challenge

E-Wave developed its WEC to solve a common problem among the offshore aquaculture industry: high operational costs. Fish farms can be 10 miles or more from the nearest accessible port and staff have to travel that distance daily by boat to feed the fish. Between travel costs, generators, and fish feeding systems, the offshore aquaculture industry relies heavily on diesel energy. Power-related costs add up quickly.

E-Wave had a solution: Instead of moving people back and forth every day and using large amounts of diesel, why not create a WEC that can power feeding systems automatically?

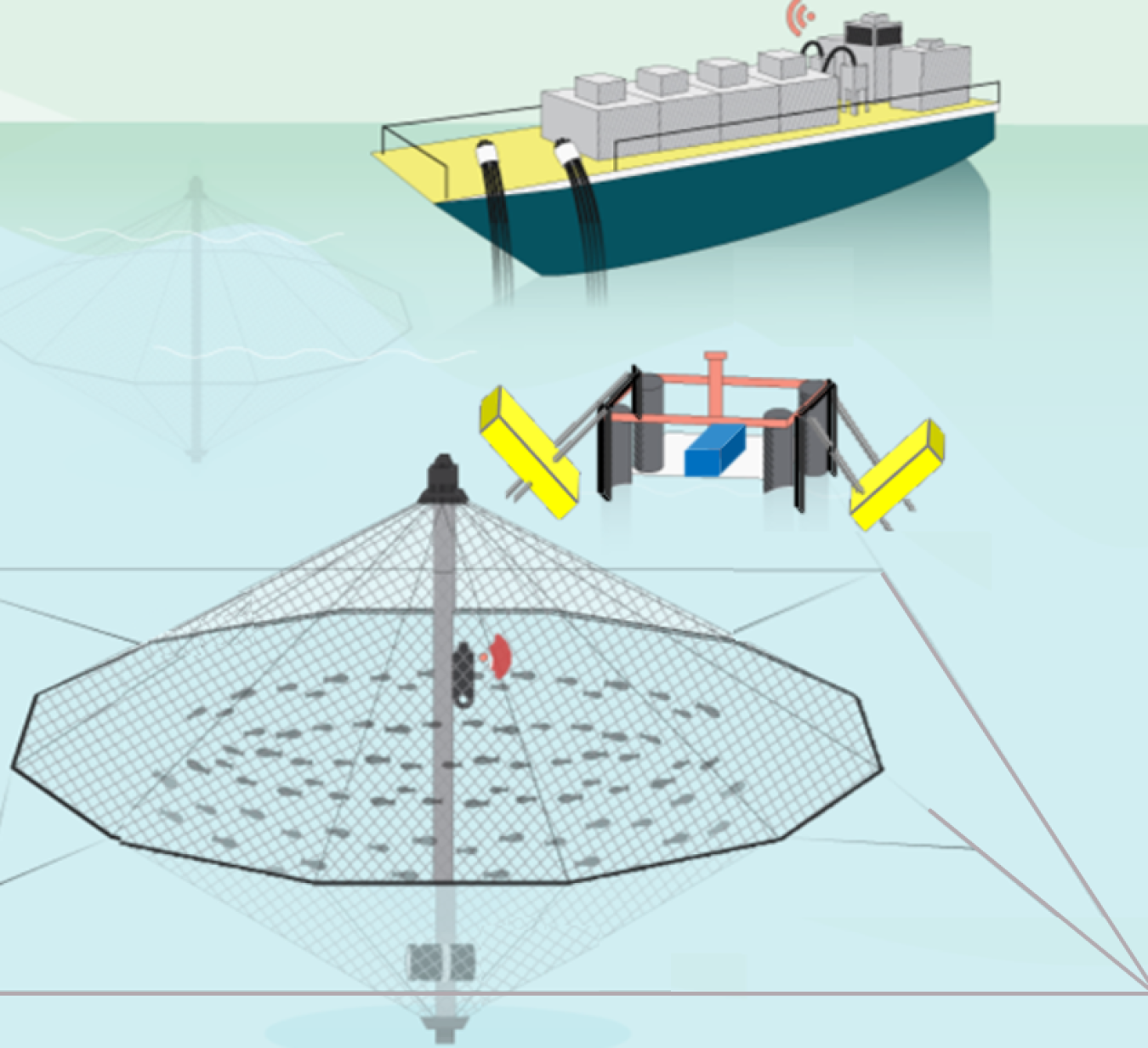

E-Wave applied for and received funding from the STTR program to work with offshore aquaculture company Innovasea Systems in Boston, and Virginia Tech. The team designed a 35 kilowatt “flap-style” WEC that can automatically power the feeding and monitoring systems of the Open Blue fish farm, which is the world's largest offshore aquaculture farm, with reduced costs and minimized environmental impacts. E-Wave's WEC captures energy through two floating, hinged flaps that respond to the rise and fall of waves. When the flap rotates downward, it pulls a winch that drives a generator to produce electricity.

Creating the device was already a valuable step for powering blue economy applications in the open ocean, but it still needed more testing and optimization to ensure it could operate as the company envisioned.

Into the Water

“TEAMER really helped us go deeper in technology development because our issues weren’t something that we could just solve with numerical models,” said Junhui Lou, cofounder of E-Wave. “We definitely needed tank testing so we could continue our work.”

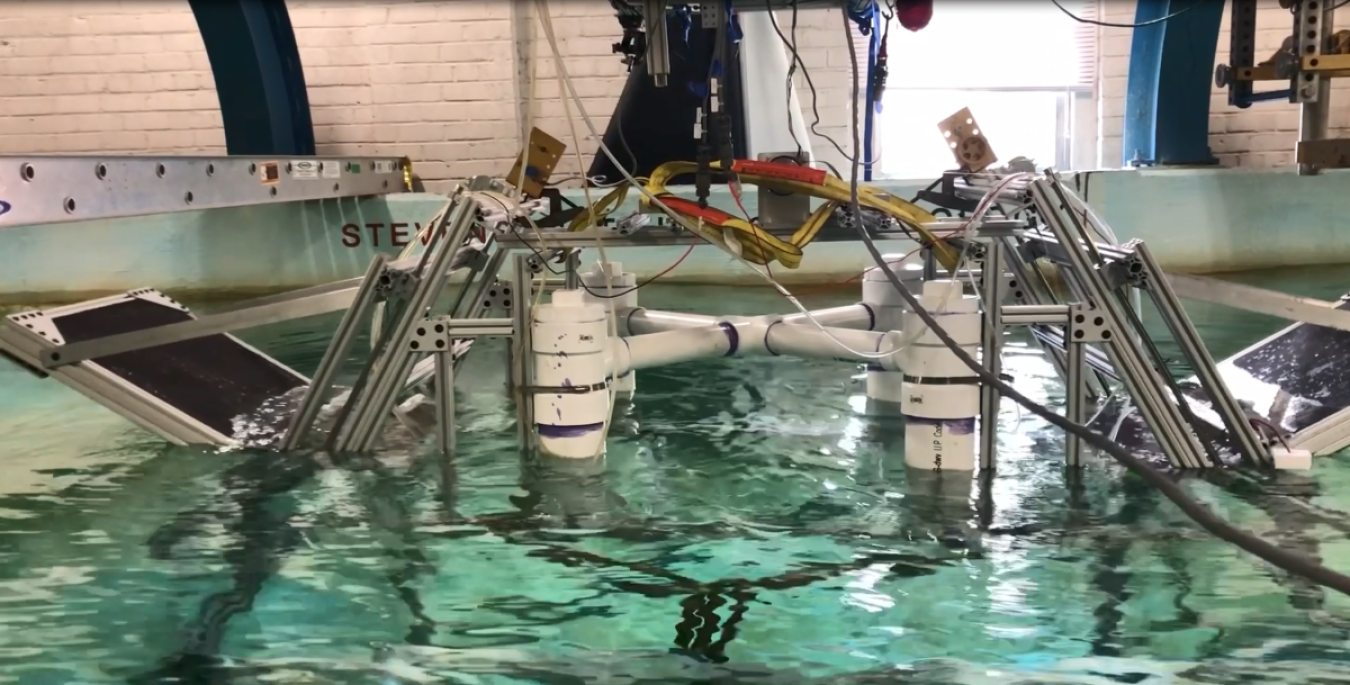

TEAMER stepped in and funded two tests of a 1/8th scale prototype in a wave tank at the Stevens Institute of Technology. The first test was geared at optimizing hydrodynamic response to waves and also validating numerical models. The second helped the team refine the power take-off system, which actually converts the ocean’s motion into electricity. Collectively, these tests ensured the team could figure out the right parts, right gear ratio, and right generator.

“When we started, we only had a concept. Access to the wave tank helped us build up the prototype and improve it. We learned a lot from those two tests. Because we’re developing a small-scale WEC, friction was a huge issue. We needed to develop the right components and the right power system as well," Lou added.

Closing in on Commercialization

Other rounds of TEAMER technical assistance helped E-Wave work with the American Bureau of Shipping on structural strength and survivability analysis to better understand how the WEC might perform during storms and on New Technology Qualification Concept Verification to validate the commercial potential of the device. Additional support enabled the team to work with Sandia National Laboratories and Pacific Northwest National Laboratory to examine coatings to prevent corrosion and biofouling, otherwise known as the accumulation of plants, algae, and other microorganisms on device surfaces.

The team is now working to schedule open water testing, which will help determine if the device can operate successfully in the environment it’s designed for and certify it for commercialization.

E-Wave is excited for their next steps and grateful for the progress it’s made with TEAMER.

“TEAMER allowed us to collaborate with partners and work on wave energy technology in multiple different aspects. Wave tank testing, biofouling, survivability—it solved all our immediate issues,” said Lou. “They also emphasized building partnerships between academia and the marine energy community. It’s a great network and great resource that we can continue to use for the future development of our technology.”

Interested in partnering with marine experts at world-class facilities to hone and develop your marine energy device? Learn more about requests for technical support through the TEAMER program.

Stay in the know with WPTO! Receive the latest information on funding opportunities, events, and other news by subscribing to the bimonthly The Water Column newsletter, as well as the comprehensive, monthly Water Wire newsletter.