Sunvapor designed a solar collector to cut costs and optimize the supply chain by using less energy to manufacture the structural components.

October 8, 2024Update on October 8, 2024: Since this success story was originally published in 2017, Sunvapor received a total of $5.8 million in U.S. Department of Energy the (DOE) funding through Concentrating Solar Power: Concentrating Optics for Lower Levelized Energy Costs (CSP: COLLECTS) funding program, the Solar Desalination funding program, the Fiscal Year 2019 CSP funding program, and the Small Business Innovation Research (SBIR) program. The company was also chosen as a finalist for Round 2 of the Solar Desalination Prize, receiving $1.25 million in cash and technical assistance vouchers through three previous phases and competing for the $1 million grand prize. Sunvapor’s innovative solar steam technology is now being deployed across more industries, including chemical production, water desalination, and additional food processing applications.

Watch the video above to learn more about Sunvapor’s recent successes and read below for more background on the breakthrough technology it developed with funding from the DOE Solar Energy Technologies Office (SETO).

Deep in the heart of California’s Central Valley, industrial food processing facilities use thermal energy to preserve, prepare, and package a diversity of food products. This massive operation requires 11 million megawatt hours of energy annually, presenting ample opportunity to use other energy sources, like concentrating solar-thermal power, to generate the heat and steam needed.

Since the 1880s, inventors have taken advantage of the rapid and efficient heating capabilities of solar as a thermal energy resource. More than a century later, Sunvapor’s technology is at the forefront of transforming industrial heat processing. In a new partnership with Horizon Nut, Sunvapor will demonstrate its sustainable solar collector and method for generating steam that will pasteurize, blanch, and roast nuts—namely pistachios.

Applying funds from SETO, Sunvapor designed a solar collector to cut costs and optimize the supply chain by using less energy to manufacture the structural components. Called the Green Parabolic Trough CollectorTM, this technology replaces expensive steel assemblies with wood, improving both the optical and structural functions of the collector without compromising heat generation. Coupled with a new manufacturing method, the new design and materials can cut the cost of the trough by as much as 50%.

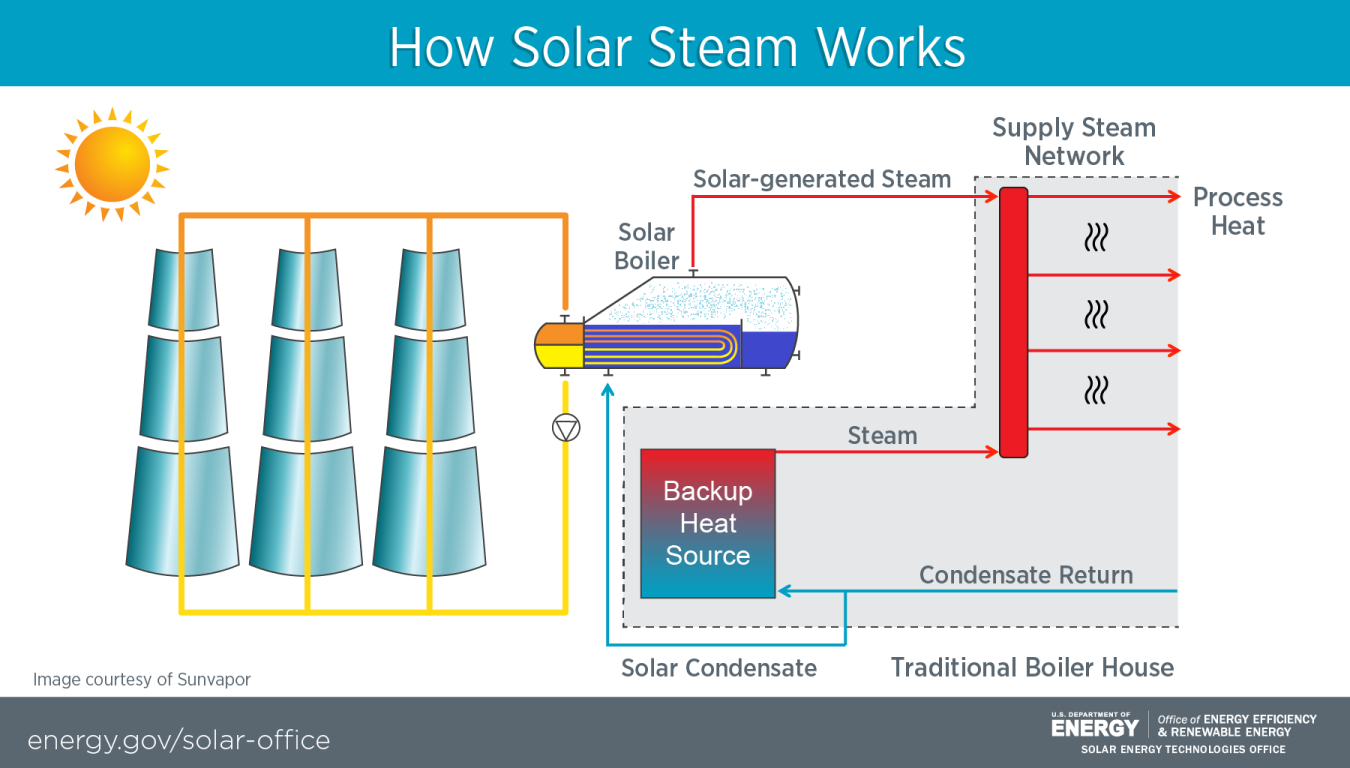

In Sunvapor’s approach, a field of mirrored parabolic troughs direct sunlight to a receiver that’s then used to heat an intermediate working fluid. This fluid boils water that’s used to heat, dry, and clean foods. While this method can also be used to generate electricity, converting energy from sunlight directly to steam reduces energy losses, making this application both highly efficient and cost effective.

With its SETO award, Sunvapor validated the feasibility of cost, performance, and durability of the new collector design. While the system is capable of efficiently operating at 500° Celsius, food processing applications only need to achieve temperatures up to 230° Celsius. Through simulation, cost estimation, and component testing, Sunvapor was able to determine that the collector’s performance is so durable it could last for 30 years.

In April 2017, Sunvapor entered into an agreement with Horizon Nut, a pistachio processor, to validate performance. The site is located in California’s agricultural heartland in the Central Valley alongside many of the nation’s food processors, many of which have similar steam needs.

Because the food processing industry is so large, Sunvapor’s solar collector and steam application represents a high-impact opportunity for greening the food processing business. This new application further demonstrates the versatile application range of solar technologies, and lays a framework for retrofitting and replacing outdated heating methods with low-cost, highly efficient concentrating solar power.

Sunvapor team performing inspection of the Green Parabolic Trough Collector shape using laser metrology. Photo courtesy of Sunvapor.

Learn more about the basics of CSP and industrial processes and SETO’s CSP research on industrial decarbonization.