The American-Made Challenges: Solar Desalination Prize is a four-stage competition designed to accelerate the development of low-cost desalination systems that use solar-thermal power to produce clean water from salt water. Competitors receive cash prizes as they advance through each stage, culminating in a $1 million grand prize for the successful testing and demonstration of a promising solar-thermal desalination system prototype.

The second round of the prize launched on April 12, 2020. Participants from private companies, nonprofit organizations, academic institutions, students, and National Laboratories submitted their ideas for a solar-thermal desalination component or system prototype, along with a pathway to commercialization.

On September 28, 2021, DOE selected 12 quarterfinalists from 7 states to advance to the second competition phase. These competitors received $50,000 in cash and will form a team and refine plans for a fully operating solar-thermal desalination system.

On April 22, 2022, DOE selected six semifinalists from three states to compete in the third phase of the competition. Each team received $250,000 and a $100,000 technical assistance voucher that can be redeemed at a National Laboratory and/or qualified partner facilities to design their systems. While they’re completing detailed designs of their systems in the third phase, teams must also obtain the permitting and approval documentation necessary to build them.

On April 18, 2024, DOE selected a finalist to advance to the fourth and final competition phase. This team received a cash prize of $750,000 and another $100,000 voucher. The team will then build its systems, demonstrate the operation, and validate key performance metrics. The team is the second finalist selected to advance, following Katz Water Technologies in Round 1.

Teams selected to advance to the fourth and final phase of the competition will be awarded a cash prize of $750,000 and another $100,000 voucher. These teams will then build their systems, demonstrate their operation, and validate key performance metrics. DOE will determine the winner, who will receive a $1 million cash prize.

Finalist

Sunvapor: Solar Hybrid Desalination Process

Location: Pasadena, CA

Sunvapor’s solar hybrid desalination process project focuses on brine management—taking in brines produced from a variety of sources, such as reverse osmosis waste, power plant cooling towers, and other waste streams with high salt content. Steam discharged from Sunvapor's Bullet Steam AccumulatorTM provides solar steam to support a hybrid low- and high-temperature desalination process. The thermal energy storage will be charged by a field of linear concentrating collectors. Together, this efficient use of thermal energy from stored solar steam has the potential to provide high-efficiency, low-cost treatment for wastewater that is too salty for reverse osmosis. Sunvapor’s initial target market is the oil and gas industry in the Permian Basin in New Mexico and Texas, where the technology will help recover clean water from produced water that is an incidental byproduct of oil and gas production. By providing a direct thermal energy resource at the location and a novel thermal desalination process, Sunvapor’s solution can desalinate produced water at low cost and with no emissions. The team plans to build a pilot facility at NGL's Striker 1 saltwater disposal facility in New Mexico to demonstrate the performance and effectiveness of the system using actual produced water.

Semifinalists

Sunvapor: SCEPTRE - Solar Cascading Evaporation Process

Location: Pasadena, CA

Sunvapor’s Solar Cascading Evaporation Process (SCEPTRE) focuses on brine management—taking in brines produced from a variety of sources, such as reverse osmosis waste, power plant cooling towers, and other waste streams with high salt content. Steam discharged from a steam accumulator provides thermal energy storage to support both low- and high-temperature desalination processes. Together, this efficient use of thermal energy from stored solar steam has the potential to provide high-efficiency, low-cost brine treatment. Sunvapor intends to demonstrate this technology at an existing saltwater disposal injection facility.

Planet A Energy: Solar Heat Collector With Built-in Storage

Location: Pasadena, CA

Planet A Energy has developed an innovative system concept that directly couples a low-cost solar collector with a low-cost thermal energy storage material that the solar collector can directly heat. The collector, absorber, and energy storage are all integrated into a single module, eliminating many of the system complexities associated with traditional CSP technologies. Planet A Energy has teamed with the Rosenblad Design Group and Aerometrix LLC. The team intends to couple Rosenblad’s proprietary evaporator technology with their collector and thermal energy storage systems at an Aerometrix desalination plant to demonstrate how this technology can be used to reduce the volume of brine wastewater.

SolMem: Solar NZLD

Location: Houston, TX

SolMem has developed a concept for desalination of various wastewater streams to produce drinking-quality water. The team’s membrane distillation (MD) technology simultaneously collects solar energy and desalinates water, greatly improving thermal efficiency and water recovery compared to conventional MD. SolMem has assembled a team that includes Winston Cone Optics and Rice University. The team intends to demonstrate their technology at the Brackish Groundwater National Desalination Research Facility.

Artic Solar: Engineered Solar-Thermal Osmosis

Location: Jacksonville, FL

A team led by Artic Solar has designed an integrated solar-thermal desalination system. The technology uses a thermally responsive solvent, which draws water from a brine stream. The solvent is then heated using an external compound parabolic concentrator, designed by Artic Solar, which separates the solvent from the generated fresh water. The team also includes technology developers of the novel desalination process and component suppliers. The team plans to test their system at Southern Company’s Water Research and Conservation Center in Georgia.

Team Trident: Temperature Swing Solvent Extraction for Zero Liquid Discharge (TSSE-ZLD) Treatment of Produced Water

Location: Santa Barbara, CA

Team Trident has an innovative concept to targets a reduction in the cost of treating high-salinity brines for water produced from oil and gas extraction. By using low-grade thermal heat to drive TSSE’s separation and solvent regeneration processes, the technology advances a non-evaporative, non-membrane solar-thermal desalination concept, which can be implemented at a low capital and operating cost. In collaboration with Columbia University and Bechtel, the team plans to construct a prototype of their system at the Brackish Groundwater National Desalination Research Facility.

Winston Cone Optics: Inland Brackish Water Desalination and Brine Concentration for Agriculture

Location: Merced, CA

Winston Cone Optics (WCO) has developed an innovative solar concentrator designed to minimize system capital costs, complexity, and operations and maintenance costs of the collector system of a solar-driven desalination process. Their technology is designed to be quick to deploy and portable, allowing solar-thermal water treatment systems to gain access to niche markets where seasonal or multi-site application is needed. WCO will couple their solar collector technology with Trevi Systems’ Switchable Solvent Water Softener technology, a forward-osmosis-based desalination system. The team will demonstrate their renewably powered, zero-liquid-discharge desalination prototype for the agricultural market with their partners, Global Water Innovation and Wacomet Water.

Quarterfinalists

Artic Solar: Engineered Solar-Thermal Osmosis

Location: Jacksonville, FL

This concept is an integrated solar-thermal desalination system that combines a non-tracking collector with a forward-osmosis desalination module. The technology uses a thermally responsive solvent, which draws water from a brine stream across a membrane. The solvent is then heated to separate it from the generated fresh water using Artic Solar’s external compound parabolic concentrator.

AeroShield: Transparent Aerogels to Improve Solar Thermal

Location: Cambridge, MA

AeroShield is developing super-insulating, transparent silica aerogels to improve the performance of solar-thermal receivers by up to 40%. These aerogels could maximize solar transmittance while minimizing heat loss, improving the performance of concentrating and non-concentrating (flat-plate) solar collectors that can deliver heat to solar-thermal desalination systems.

Sunvapor: Solar Cascading Evaporation Process

Location: Pasadena, CA

This technology takes in and treats brine using thermal energy from low-cost solar steam. Brine sources may be reverse-osmosis waste, power plant cooling towers, or other waste streams with high salt content. A steam accumulator discharges steam to provide thermal energy storage to support low- and high-temperature desalination processes. In the high-temperature stage, the accumulator uses a thermocompressor, which uses thermal energy to compress the steam, and in the low-temperature stage it uses a membrane distillation process.

Team Trident: TSSE-ZLD Treatment of Produced Water

Location: Santa Barbara, CA

This concept aims to reduce the cost of treating high-salinity brines produced from oil and gas extraction by using a multi-stage temperature-swing solvent extraction technology for zero liquid discharge (TSSE-ZLD). This technology swings from high to low temperatures to extract water from brine. By using low-grade thermal heat to drive TSSE’s separation and solvent regeneration processes, the technology advances a non-evaporative, non-membrane solar-thermal desalination concept, which can be implemented at low cost.

Physical Sciences: Modular Inexpensive Solar Thermal Evaporative Desal

Location: Andover, MA

Physical Sciences has developed an integrated solar-thermal collector and desalination system to produce low-cost fresh water for small- to medium-scale systems (that produce 100 cubic meters daily or less). This concept has individual concentrating solar-thermal modules with glass receiver tubes in which salt water is distilled by multi-stage flash—a process that boils water to make steam, which is condensed and collected as fresh water. The goal is to combine the low-cost simplicity of a solar still with the thermal efficiency of multi-stage flash to reduce complexity and materials costs compared to traditional, high-temperature concentrating solar-thermal power equipment.

ORNL Solar Desalination: Modular Intensified Solar-Desal Technology

Location: Oak Ridge, TN

Researchers from Oak Ridge National Laboratory will produce fresh water from high-salinity water, with zero liquid discharge so that easily disposable salt is the only waste product, using a black graphite foam as a solar energy absorber and heat conductor. The graphite directly heats up salt water to produce fresh-water vapor, and by using a superhydrophobic coating on the surface of internal channels to repel water, this can be efficiently coupled to high-efficiency membrane distillation process, without requiring a heat-transfer fluid or electrical-to–thermal energy conversion.

Winston Cone Optics: Portable Optics for Solar Heat

Location: Merced, CA

Winston Cone Optics has developed a low-cost, compact solar concentrator designed to minimize system capital costs, complexity, and operations and maintenance costs of a solar desalination collector system. It is designed to be quickly deployable and portable, allowing solar-thermal water-treatment systems to enter niche markets that need seasonal or multi-site applications. Unlike traditional solar-thermal collectors, this concept does not require tracking and tilting to perform well. It also allows modules to be installed next to each other, without casting shade, so they can fit in limited areas.

Winston Cone Optics: Integrated Compound Parabolic Concentrator

Location: Merced, CA

Winston Cone Optics has developed a non-tracking solar-thermal collector called the integrated compound parabolic concentrator (ICPC) for process-heat applications up to 150°C. The ICPC is designed to maximize solar-to-thermal efficiency, with limited or no tracking, through a silver coating that reflects light toward an aluminum mini-channel absorber. The absorber has a selective coating that maximizes solar absorption and minimizes thermal emissions. As a result, the ICPC has the potential to heat fluids at more than 50% solar-to-thermal efficiency.

Planet A Energy: Solar Heat Collector with Built-in Storage

Location: Pasadena, CA

This system couples a low-cost solar collector with a directly heated low-cost thermal energy storage material. The collector, absorber, and energy storage are integrated into one module, eliminating many system complexities associated with traditional concentrating solar-thermal power. The design uses an inert solid material as both an absorber and a storage medium. It provides integrated long-duration storage for around-the-clock operation for solar-thermal desalination and other process-heat applications.

SolMem: Solar NZLD

Location: Houston, TX

This concept combines a solar-thermal-driven multi-effect membrane distillation (MD) process with electricity-powered reverse osmosis (RO) to desalinate various wastewater streams and produce drinking-quality water. The MD technology uses a nanophotonics-enabled photothermal membrane that converts light to heat to simultaneously collect solar energy and desalinate water. This improves thermal efficiency and water recovery compared with conventional MD. The conceptual hybrid system combines the low energy consumption of RO with the high salt tolerance of MD while mitigating the disadvantages with near-zero liquid discharge (NZLD) so salt is just about the only waste product.

D&D Manufacturing: Concentrated Solar Multi Effect Distillation

Location: Fletcher, NC

D&D Manufacturing and Low Impact Technologies USA Inc. are working together to develop a solar-thermal multi-effect distillation (MED) process that can handle a wide range of input brine salinities. The team developed a low-cost, thermoplastic parabolic trough that provides heat to a solar-thermal desalination process. Thermoplastic allows for a more precise trough design because it can be melted, then molded. The trough acts as both the solar collector and a horizontal distillation column. The system is designed to recapture the heat of vaporization of the produced water vapor to maximize thermal efficiency. This technology is modular, scalable, and can potentially support zero-liquid discharge requirements for various applications.

Frontier Research Group: Clouds & Rain: Optimum Solar Thermal Desalination

Location: San Marcos, TX

Frontier Research Group is developing a humidification-dehumidification (HDH) approach to desalination with a combination of technologies designed to optimize solar-thermal desalination over a range of salt concentrations. This concept significantly enhances the HDH process by creating sub-millimeter microbubbles with hot air, called sparging. Solar energy directly heats air and salt water through a compound parabolic concentrator. Then the air and salt water are mixed to improve heat transfer and evaporation. To collect fresh water, condensation is enhanced with advanced materials that form superhydrophobic structures, which repel water. This combination of technologies is a novel design that could be used in various solar-thermal desalination markets.

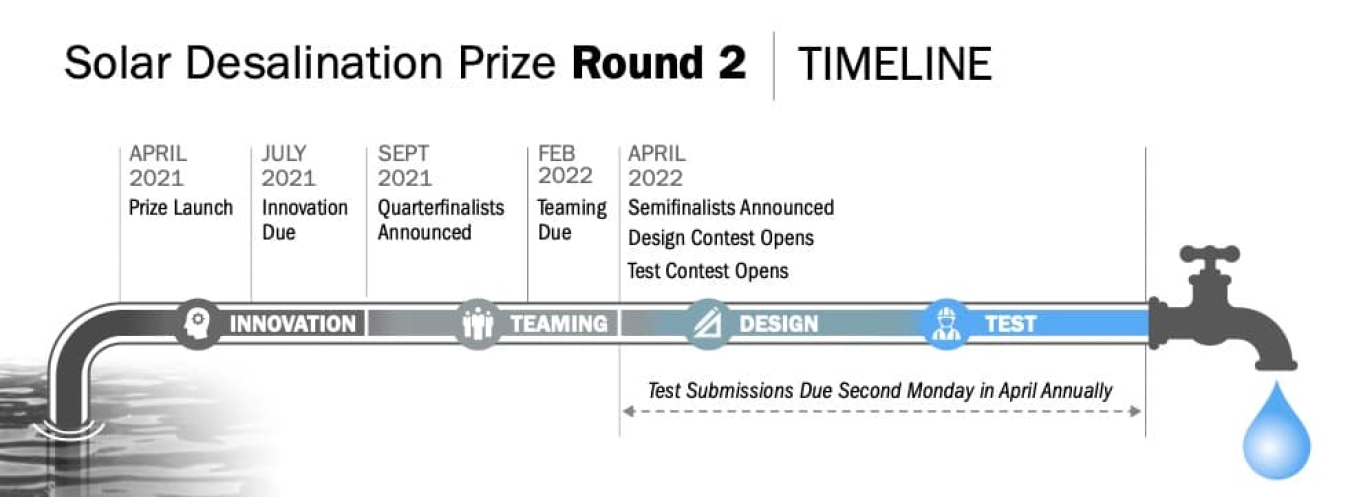

Timeline

- Innovation: The first phase opened on April 12, 2021, and will close July 15, 2021. Quarterfinalists were announced on September 28, 2021.

- Teaming: The second phase opened on September 28, 2021, and close February 9, 2022. Semifinalists were announced on April 22, 2022.

- Design: The third phase opened on April 22, 2022, and will close when competitors have completed their designs and obtained the required documents, no later than April 10, 2025.

- Test: The fourth phase opened on April 18, 2024. Submissions will be evaluated annually on the second Monday in March, starting in 2023. Winners will be determined approximately one month after visits to their newly built system sites.

Learn More

- Visit the Solar Desalination Prize website for details on the competition.

- Learn more about Round 1 of the competition.

- Join the American-Made Network.

- Watch a recording of the May 4, 2021 informational webinar that explains how the competition works.

- For questions about the Solar Desalination Prize, email challenge@nrel.gov.

The Solar Desalination Prize is administered by the National Renewable Energy Laboratory and is part of the American-Made Challenges.