With the help of DOE funding, PhosphorTech is using plasmonic nanometals to enhance phosphor film performance while reducing phosphor material usage by up to 50% and film manufacturing cost by up to 60% for some colors. The company has achieved this through increased blue-light absorption, which has enabled equivalent color conversion with less phosphor materials compared to the original phosphor films. An additional benefit is the reduction of manufacturing time and cost required for the fabrication of the corresponding phosphor sheets.

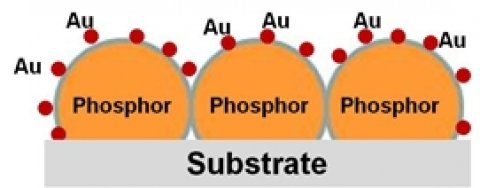

Phosphors are integral to PhosphorTech’s RadiantFlexTM down-converting films. By using nanometals such as gold, silver, and copper to induce a process referred to as “localized surface plasmon resonance,” the company has achieved a reduction in phosphor use of up to 50%, with a concurrent increase in useful light output of 45%. This method preserves the spectral performance of PhosphorTech’s current phosphor blends and will be incorporated into the company’s future products.

It’s also believed that these films could be cost-effectively integrated into popular LED lamp products, which would use blue LEDs instead of white phosphor-converted LEDs (pcLEDs). Even though today’s blue LEDs are more expensive than white pcLEDs, it’s widely held that if the demand for blue LEDs exceeds that for white LEDs, blue LEDs will become cheaper, because they’re simpler to manufacture. Also, by depending on down-converting films bonded to LED wafers or packages instead of the designs that are presently used for pcLEDs, a number of manufacturing problems and unwanted spectral variations could be reduced or eliminated. What’s more, reducing phosphor use will proportionately cut the use of rare-earth phosphors, which could become a critical material as demand increases or if supply chains are interrupted.

While this achievement was demonstrated in remote phosphor films typically used for theatrical, broadcast, and agricultural applications, similar performance is expected in films designed to be compatible with the pcLED architecture currently used in the bulk of LED lighting products today. (December 2016)

Return to Research Highlights.