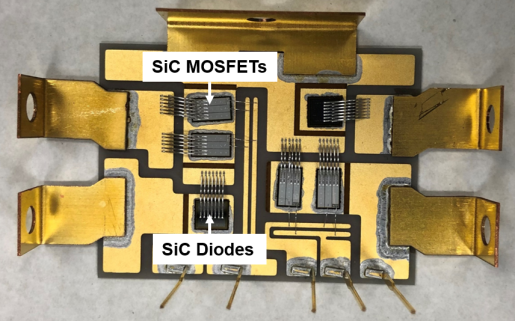

The Solar Energy Technologies Office (SETO) supports research and development projects that advance the understanding and use of the semiconductor silicon carbide (SiC). SiC is used in power electronics devices, like inverters, which deliver energy from photovoltaic (PV) arrays to the electric grid, and other applications, like heat exchangers in concentrating solar power (CSP) plants and electric vehicles.

When PV modules generate electricity, energy first flows through a power electronics device that contains a semiconductor. Until around 2011, silicon was the preferred semiconductor used to make these devices, but research has shown that SiC can be smaller, faster, tougher, more efficient, and more cost-effective.

SiC withstands higher temperatures and voltages than silicon, making it a more reliable and versatile inverter component. Inverters convert direct current electricity generated by solar panels from to grid-compatible alternating current. During the conversion process, some energy is lost as heat. State-of-the-art silicon inverters operate at 98% efficiency, whereas SiC inverters can operate at about 99% over wide-ranging power levels and can produce optimal quality frequency. While the 1% increase in efficiency might seem small, it represents a 50% reduction in energy loss. With 60 gigawatts of solar installed in the United States, a 1% increase in efficiency would amount to 600 megawatts of additional solar power each year and cost savings over the device’s lifetime.

Benefits of Silicon Carbide

SiC has an edge over silicon because it enables the following:

- Higher temperatures: SiC-based power electronics devices can theoretically endure temperatures of up to 300° Celsius, while silicon devices are generally limited to 150°C.

- Higher voltage: Compared with silicon devices, SiC devices can tolerate nearly 10 times the voltage, take on more current, and move more heat away from the energy system.

- Faster switching: A power electronics device needs a switch that turns on to convert low voltage to higher voltage. SiC can switch on and off quickly, and although some energy is lost during switching, faster switching limits that loss and improves device efficiency.

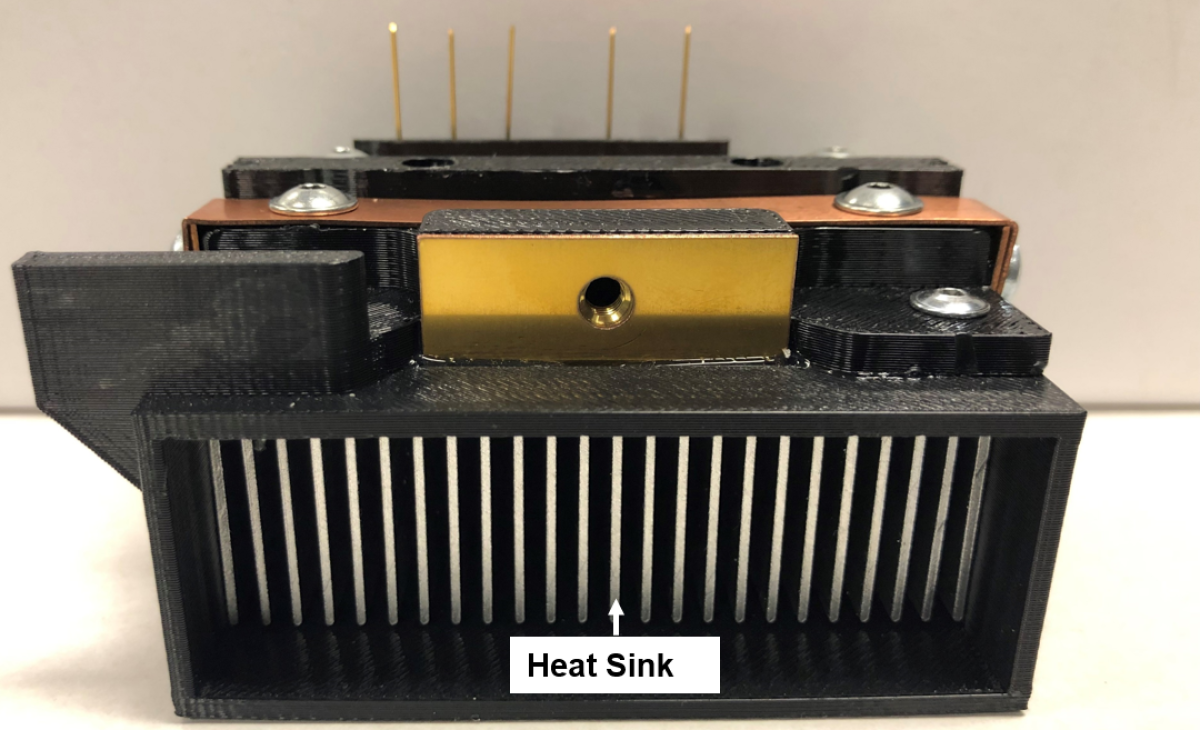

- Less-costly equipment: SiC translates to lower system costs because it allows for smaller, more affordable equipment. For example, the heat sink, which protects the rest of the components by taking on excess heat, can be smaller because with less energy loss, less heat is produced.

The Wide-Bandgap Advantage

One attribute is responsible for these benefits: SiC’s wide bandgap. The bandgap is a measure of energy that signifies the distance between two states—an electron’s starting point in the valence band, which is the nonconduction state, and the level it has to move to in order for electricity to flow. The wide bandgap allows for high voltage, which means SiC can better tolerate voltage spikes, and because devices can be thinner, they perform faster.

Solar and Silicon Carbide Research Directions

Inverters and other power electronics devices are processed on wafers, similar to building integrated circuits on silicon. And just like silicon, as time has progressed, the wafer sizes have increased, making it process more circuits per batch and lowering cost. The cost of a 4-inch wafer dropped by half between 2009 and 2012 thanks in part to fabrication improvements and a higher rate of production. At the same time, sales of SiC devices more than tripled. Around 2015, typical wafer size increased to about 6 inches in diameter.

Now researchers are working to expand the use of SiC to the national grid by developing power electronics devices that link distribution lines to transmission lines. This could potentially do away with huge transformers and save energy. SiC could save energy in other areas, too, especially in electrification of transportation.

In 2017, SETO launched a funding program to examine some of these issues. The Advanced Power Electronics Design for Solar Applications awardees have several projects involving silicon carbide:

- Flex Power Control, Inc.

- North Carolina State University

- Oak Ridge National Laboratory

- University of Arkansas

- University of Texas at Austin

- University of Washington

Some of these projects focus on making inverters and converters that last longer, work more efficiently, and reduce costs. Others are furthering grid integration by designing devices that can connect with energy storage or load-management devices, detect and respond to abnormal current, or rapidly restore power after an outage. Through this work, SETO aims to develop tools that help grid operators better control solar generation, enable delivery of solar through microgrids, increase grid resiliency, and improve solar reliability for customers. Learn more about our systems integration research.

In addition, three semifinalists in the first round of the American-Made Solar Prize, a competition to revitalize U.S. solar manufacturing, are developing SiC devices: Infineon Technologies America is working on a 1,500-volt converter, BREK Electronics is working on a 250-kilowatt string inverter, and Imagen is working on a three-port high-frequency conversion system.

SiC can also be processed into a ceramic for CSP applications. Such ceramics move heat well. SETO is funding a project team at the University of Utah that’s using SiC to design and develop a stable receiver to absorb sunlight, and researchers at Argonne National Laboratory who are using SiC and the ceramic mullite to create a new heat exchanger through additive manufacturing, or 3-D printing. Learn more about our CSP research.