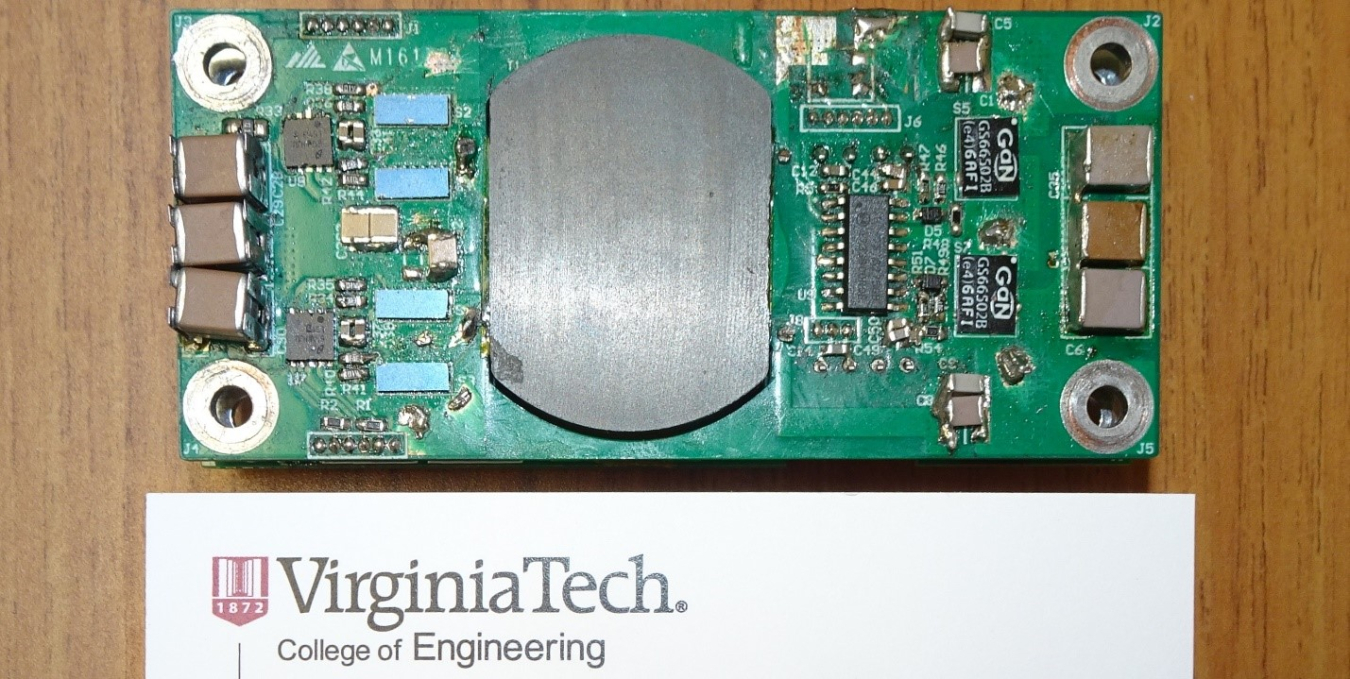

Project Name: Ultra Compact Electrolyte-Free Microinverter with Megahertz Switching

Funding Opportunity: Advanced Power Electronics Designs for Solar Applications

SETO Subprogram: Systems Integration

Location: Blacksburg, VA

SETO Award Amount: $1 million

Awardee Cost Share: $260,000

This project team will build a high-power-density, cost-effective photovoltaic (PV) microinverter using the wide-bandgap semiconductor gallium nitride (GaN). A microinverter converts a single PV panel’s direct-current (DC) output into alternating current (AC) for use on the electric grid, and the bandgap is a measure of energy that signifies the distance between an electron’s starting point and the point it has to move to in order to conduct electricity. GaN enables the microinverter to operate at megahertz frequencies, which means it can switch on and off millions of times per second. Megahertz frequencies also mean components can be much smaller without sacrificing efficiency, lowering costs.

APPROACH

The team will design a one-megahertz switching microinverter containing GaN so that it’s small, lightweight, and can be easily attached to a solar panel. The microinverter will be designed to achieve a power density of 150 watts per cubic inch—an order of magnitude higher than current state-of-the-art inverters. The team will select GaN switches, compute losses in each stage of the power conversion process, design magnetic components, analyze costs, and then test to verify cost, power density, efficiency, and lifetime targets.

INNOVATION

This project is a holistic GaN-based microinverter design that will examine each individual component and subsystem in the device to ensure the device meets cost and efficiency targets. The wide-bandgap semiconductor allows the signal control to operate at very high frequency, increasing power density. Smaller passive components, such as filters and capacitors, allow for smaller packaging so the microinverter can fit in the junction box of a solar panel. This is made possible by the higher operating frequency that comes with megahertz switching. Furthermore, the design eliminates the need for electrolytic capacitors, leading to improved reliability.