Project Name: Full Loop Thermodynamic Corrosion Inhibition and Sensing in Molten Chloride Systems

Funding Opportunity: Generation 3 Concentrating Solar Power Systems Lab Call

SETO Subprogram: Concentrating Solar-Thermal Power

Location: Aiken, SC

SETO Award Amount: $1,000,000

Awardee Cost Share: N/A

This project explores ways to prevent corrosion from molten chloride salts in Generation 3 concentrating solar power (Gen3 CSP) plants. Gen3 CSP systems will operate at temperatures as high as 750° Celsius, making them more efficient, but this requires a fluid, such as molten salt, that can move high-temperature heat without breaking down. Molten salts are cost-effective; however, if not properly controlled and maintained, they will corrode the metal pipes and other components in the system. Preventing corrosion is essential to extend the lifetime of the components in a CSP plant and keep costs down.

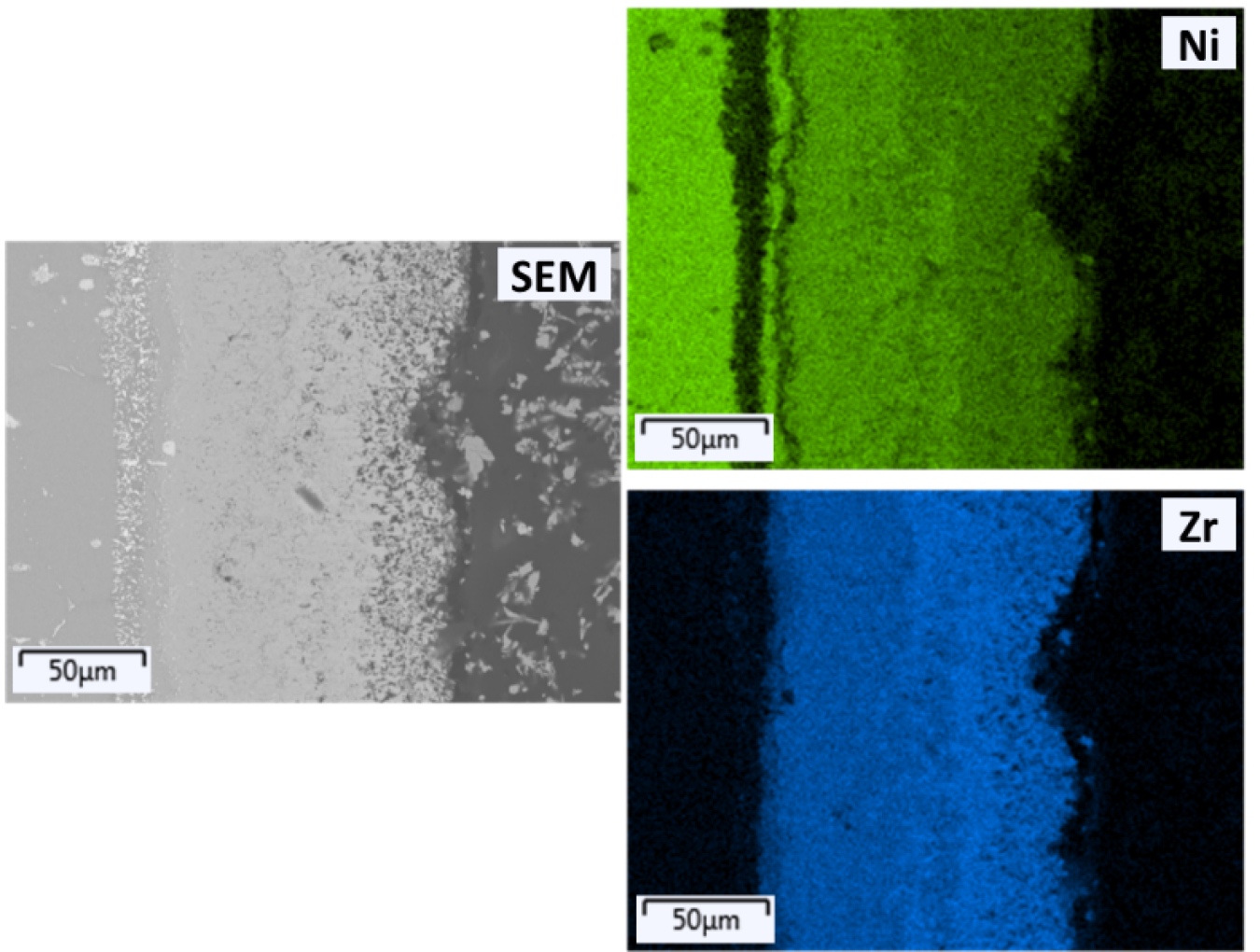

Left: A scanning electron microscope image of a nickel alloy used for CSP after exposure to corrosive salts. Right: Green areas contain nickel, and blue ones contain zirconium. Photos courtesy of Savannah River National Laboratory.

APPROACH

Savannah River National Laboratory has demonstrated that adding electrochemically active metals, like magnesium, to a molten salt mixture can control corrosion, though questions remain about how to best deploy this strategy in an operating plant. To develop corrosion-mitigation strategies for CSP plants, the team will explore various options, including lowering the melting point of magnesium by mixing it with other metals; coating the metal components with zirconium or titanium; and adding zirconium chloride or titanium chloride to the molten salt. The project team will also develop new methods for detecting corrosion as it occurs.

INNOVATION

The proposed corrosion-prevention methods use elements that can both maintain a low electrochemical potential in the metal, meaning they make the metal less susceptible to corrosion, and facilitate the formation of a protective layer—stable carbide films—on it. This project will help reduce corrosion, making plants easier to maintain and more economical.