Solar panels need to withstand the elements to keep producing power for decades, and water is one of a solar module’s trickiest foes. Using clever measurement and modeling methods, researchers are optimizing the way we seal solar modules to keep water out

Solar Energy Technologies Office

May 4, 2023Solar panels need to withstand the elements and are expected to keep producing power for decades. A solar module’s trickiest foe? Water. Water can seep into a module through the tiny seal around its edges and reduce its efficiency and durability, but creating a solar module that stays perfectly sealed for its entire lifetime is impractical.

Two decades of research headed by scientists at the National Renewable Energy Laboratory (NREL) has shaped our understanding of how water gets into solar modules. Now, that knowledge has been transformed into tools that can help to optimize the way solar modules are sealed and improve sealant materials.

When solar energy started to be deployed rapidly across the United States in the early 2000s, solar energy research was focused on increasing the efficiency and decreasing the costs. Once solar panels were out in the field, though, researchers faced a new challenge: increasing the durability of the panels so that they endured all types of weather conditions.

To do this, scientists needed to understand how water was seeping into the cells and accurately measure it. This information was especially important for thin-film solar cell materials like cadmium telluride (CdTe) and copper indium gallium diselenide (CIGS), which are more sensitive to moisture than other solar cell materials like silicon.

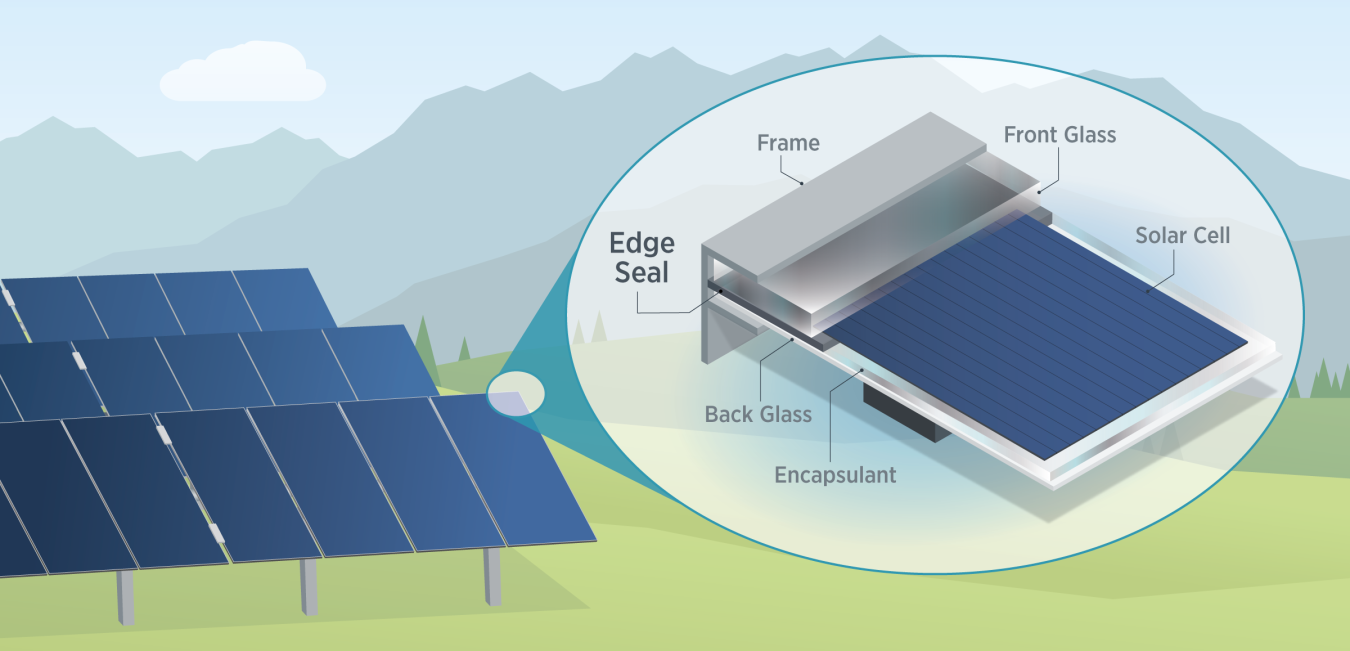

Generally, thin-film solar cells are encapsulated between two sheets of glass. While the glass itself is excellent at keeping water out, water can enter through the edges where the two glass sheets are sealed together. The modules are sealed with a polymer material similar to those used to seal glass windows. These sealant materials are soft and flexible, and sometimes have substances that soak up water—known as desiccants—mixed into them.

The structure of a thin film solar module is shown in the inset. The solar cell materials are sandwiched by two glass panels and sealed around the edges. This edge seal is where water is most likely to enter the solar module.

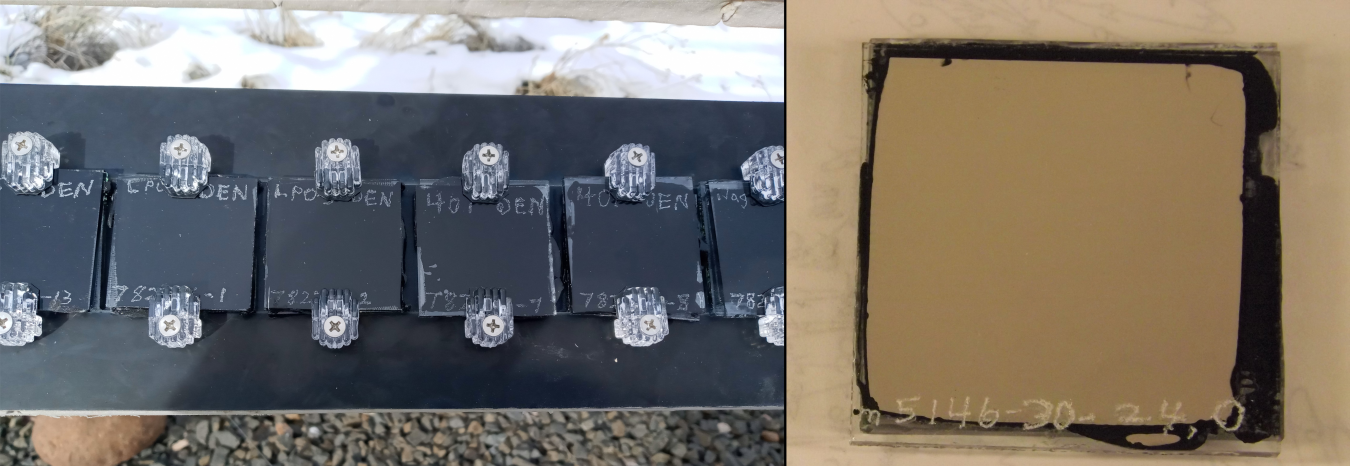

Researchers at NREL used a quick, simple technique to measure when and how quickly water moves through the edge seals that’s as easy as snapping a picture. They place a layer of calcium between two pieces of glass and enclose it with the same edge seal materials used for solar cells. Then, they place this calcium film in environments of varying temperature, humidity, and other conditions, both in a controlled lab setting and in real-world outdoor conditions.

When it is first made, the calcium metal layer has a shiny, mirror-like appearance. As water moves in through the edge seals, it reacts with the calcium and turns it transparent. Researchers take photos of the calcium layer at regular intervals and can measure how much of the film has become transparent at the edges by simply counting pixels to determine how much water is getting in through the edge seals. NREL also developed a technique to make this test even more sensitive by measuring the electrical resistance of the calcium metal.

Left: Outdoor testing setup for a row of samples with a calcium layer sandwiched between glass and enclosed with the same edge seal materials used for solar modules. This allows researchers to measure how edge seals perform in real-world conditions. Right: A sample that has been outdoors at NREL for nearly a decade—since 2013—still shows the shiny mirror finish of the calcium layer, indicating that the edge seals are performing well in keeping water out.

This simple method allows researchers to run multiple tests with different edge seal thicknesses, edge seal materials, and environmental conditions mimicking a variety of climates. Using this data, the researchers created mathematical models to predict how an edge seal would perform in a certain climate for the decades-long lifetime needed for the solar module to be commercially viable.

This method has allowed for substantial improvements in solar module technology, testing, and manufacturing. For example, researchers at NREL worked directly with the company First Solar to develop and analyze the sealants they use in their commercial CdTe solar modules.

Additionally, researchers learned that the thickness of the required edge seal could vary substantially based on climate. This could allow solar cell manufacturers to optimize edge seal thickness for location-specific products, which would reduce costs without sacrificing durability.

Now, this method is being used to develop stable perovskite solar cells. Perovskites are a promising new thin-film solar cell material, but they break down quickly when exposed to moisture. Increasing the durability and lifetime of perovskite solar cells is critical for these materials to reach commercial success.

Through collaborations with other national labs, academic researchers, and solar cell manufacturers, this measurement and modeling method is accelerating the development and deployment of new technologies.

Explore the photovoltaics research funded by the U.S. Department of Energy Solar Energy Technologies Office and learn how solar photovoltaic technology works.