DOE’s SBIR/STTR program provides grants to small businesses or individuals who can form a small business within the required application timeline.

Industrial Technologies Office

November 29, 2018DOE’s SBIR/STTR program provides grants to small businesses or individuals who can form a small business within the required application timeline. Grants are competitively awarded for the development and commercialization of new ideas and innovative research. To date, DOE and EERE SBIR/STTR programs have provided funding to thousands of small businesses, including newly established small businesses, across the country. Letters of Intent are due December 17 for Phase I Round II topics.

We sat down with some past awardees to learn about how the program has impacted them. If you’re considering applying, read our interviews below and hear firsthand how an SBIR/STTR grant helped propel their business.

Interviewee: Guillermo Garcia, Co-founder and Chief Science Officer

Location: Oakland, CA

Accomplishment: In July 2013, R&D Magazine awarded the Universal Smart Window Coating with an R&D 100 award, recognizing it as one of the year’s top technology products from industry, academia, and government-sponsored research. The Universal Smart Window Coating is designed to limit heat gain generated from the sun without blocking visible light, allowing building owners and operators to reduce the energy used for thermal management by up to 30% and peak loads by as much as 50%. Since receiving its SBIR grant, Heliotrope has made several strategic partnerships and has been refining its technology. The company and its partners plan to hit commercial markets in early 2019.

Employees: 40

Funding: SBIR Phases I and II, $1,150,000

What made you decide to apply for an SBIR grant?

SBIR/STTR grants are great sources of non-dilutive capital for early stage companies. They provide two major advantages: (1) they help advance the technology through continued funding, and (2) they put the company in a good position to attract future investment from private funding. We made the decision to apply for SBIR/STTR grants for both reasons.

How important was the SBIR grant in advancing your technology?

It was critical in the early stages of the company because it was a reliable source of capital that helped us address technical risk flagged by future investors. With these funds, we were able to mitigate the technical risk and land private investment. Without this aid, we would have never de-risked the product and landed future [quality] investment.

What was the best thing about your awards?

Ultimately, it was the capability of being able to work on advancing the technical progress without sacrificing ownership.

Picture of the Heliotrope team with their product demo | Photo courtesy of Heliotrope Technologies

Interviewee: Gary Cola, Founder and Chief Technology Officer

Location: Washington, Michigan

Accomplishment: In 2018, SFP Works was recognized as a 2017 SBIR/STTR Small Business of the Year award for developing and being on the path to commercializing Flash Bainite®—a novel process for producing weldable, highly formable steel that is 20%–25% stronger than other products for use in the automotive industry. Since receiving SBIR grants, SFP Works has attracted more than $700,000 in venture funding in the past 6 months, and the company has made some sales to defense contractors building vehicles for the U.S. military. The company is also in negotiations for several licensing agreements.

Employees: 5

Funding: SBIR Phase I, II, IIB, and III, $3,249,940; HPC4Mfg Round 5, $300,000

What made you decide to apply for an SBIR grant?

We had developed a steel treatment for the Army that stopped armor piercing bullets. It made ordinary steel very strong but not brittle and we were looking for other applications. The EERE SBIR topic on manufacturing lightweight materials for auto bodies gave us an opportunity to adapt the technology for other markets.

How important was the SBIR grant in advancing your technology?

Getting an SBIR phase I grant really put us on the map –investors would listen to us. Getting the Phase II made it clear this was a real technology and it attracted Detroit’s Auto OEMs to us. Getting the Phase III and other recognition like the SBIR Small Business of the Year got everyone’s attention and is paving the way to commercialization of our technology by giving us the resources build full blown production scale equipment.

What is the best thing about the award?

The no-cost share money was nice but the biggest benefit was the ability to interact with world class metallurgists like our brilliant Advanced Manufacturing Office Program Manager David Forrest and his network like the researchers at the Ohio State University, the University of Tennessee-Knoxville and Oak Ridge National Laboratory. Getting David’s insights for free was the best thing about the award and it really spurred us to think differently and make our steel even stronger, lighter, and tougher at low cost in a less polluting way.

Pictured here is the pilot line for SFP Works to process 20,000 lb coils through the Flash Bainite® process. Photo courtesy of SFP Works

Interviewee: Samir Mayekar, Co-Founder & CEO

Location: Chicago, IL

Accomplishment: After receiving a Phase I SBIR award, the SiNode team went on to win the DOE-sponsored National Clean Energy Business Plan Competition for its battery anode material. SiNode showed its novel Si- graphene composite technology’s high potential to overcome existing limitations on energy and power density while minimizing costs compared to alternative solutions. Solution-processed SiNode anodes use highly developed, relatively cheap components and are compatible with current manufacturing processes while providing superior performance-to-cost metrics compared with plasma deposition and other technologies. At the conclusion of the Phase II SBIR award, SiNode exports about 90% of its products to Japan and Korea. The company has received follow-on investments and revenues amounting to over 5 times the original DOE SBIR investment.[1]

Employees: 15

Funding: 2013 Business Plan Competition, $100,000; SBIR Phase I and II grants $1,150,000; DOE funded contract through the U.S. Advanced Battery Coalition, $1.75M (SiNode cost shared $1.75M)

What made you decide to apply for an SBIR grant?

Our team applied for an SBIR grant while we were still graduate students and on the hunt for capital to help us take our company concept to the next level. One of our entrepreneurship professors encouraged us to look at the SBIR program, and we immediately applied for a Phase I award when we found a topic that was directly related to our technology area. The process of assembling the application helped us mature the company, as it was the first time we had ever applied for major funding. We learned how to communicate our technology roadmap and key milestones, found a lab space outside of Northwestern University where we would spin out if awarded an SBIR, and assembled a qualified team to advance the company.

How important was the SBIR grant in advancing your technology?

The SBIR grant was critical in our early days by advancing the readiness level of our technology in three ways. First, having an SBIR award gave our team a certain level of credibility when speaking with potential investors. When we won the 2013 Rice Business Plan Competition (the world’s richest pitch competition for students), many of the judges provided feedback that our SBIR grant served as an early validator of our technology and team given the low success rate for winning Phase I awards. A second important outcome of the SBIR award was meeting new customers and collaborators at the [Vehicle Technologies’ Office] Annual Merit Review (AMR). While presenting a poster on our technology at the AMR, we met several technology scouts from large chemical and battery manufacturers who have since become our customers, suppliers, and partners. Finally, our consistent engagement with our DOE program manager helped provide us with feedback on our technology roadmap and where we had gaps to fill. The direct feedback provided by our program manager helped us shape our technology development plan to better achieve important milestones.

What was the best thing about your award?

The award provided us with seed capital at a time when we had minimal funding, so I can confidently state that SiNode would not exist today in its current form without that early risk capital. Additionally, the SBIR award helped introduce us to the technology community in our industry and enabled us to build a network with the right university, national lab, and industry collaborators.

[1] https://science.energy.gov/sbir/highlights/2017/sbir-2017-01-c/

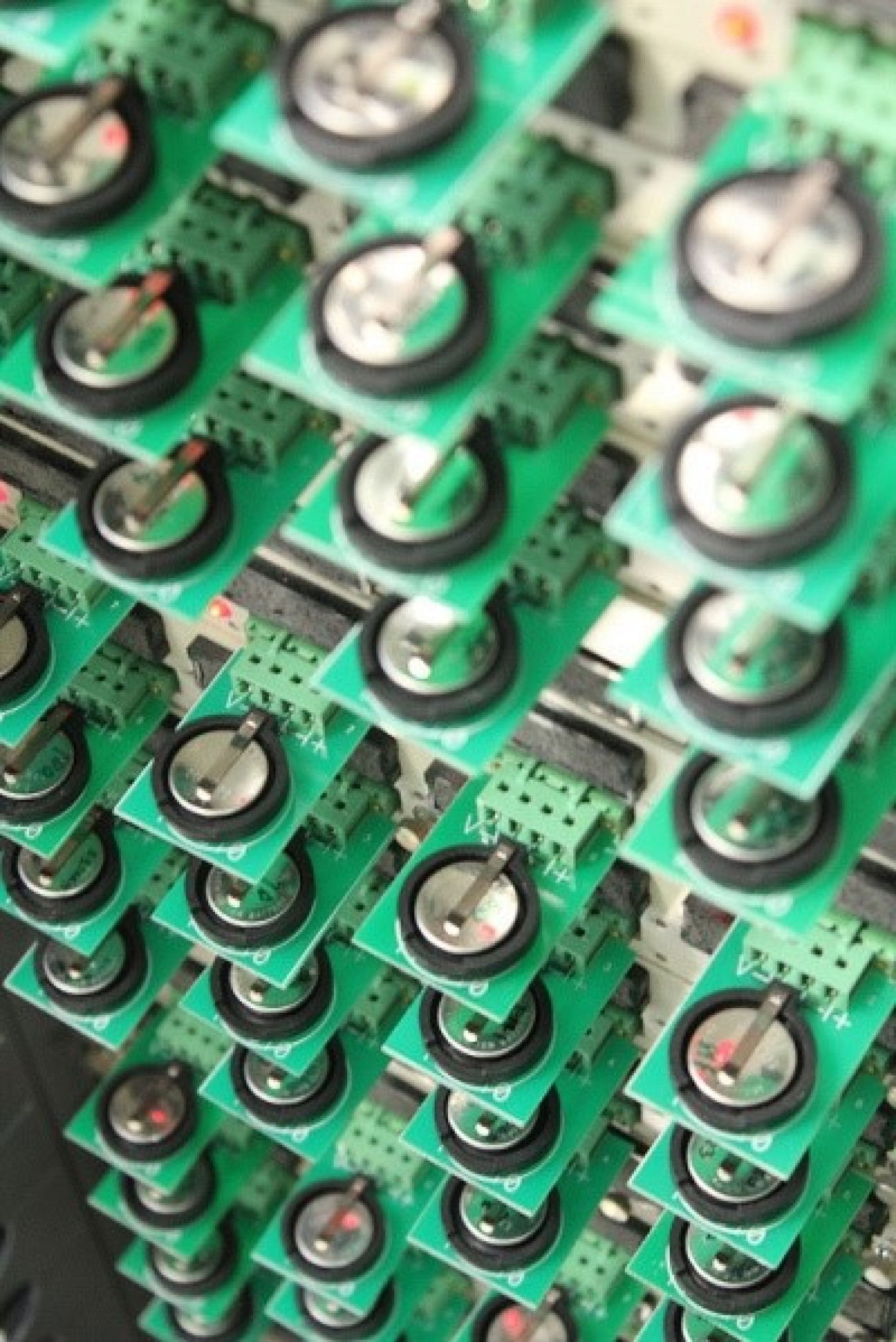

Advanced silicon graphene batteries. | Photo courtesy of Sinode Systems.