Project Website: https://obc.lbl.gov/

Performers:

-- Lawrence Berkeley National Lab – Berkeley, CA

-- Pacific Northwest National Lab – Richland, WA

Partners:

-- kW Engineering – Oakland, CA

-- Taylor Engineering – Alameda, CA

-- Building Intelligence Group – Portland, OR

Performance Period: October 1, 2019 – September 30, 2021

Funding Source: 2018 core Sensors and Controls lab call

Budget: $2,250,000

Related Projects: Spawn, BOPTEST, Data Center Toolkit

Project Objective

A properly designed, implemented, and maintained HVAC control strategy can reduce commercial building energy consumption by 20-30%. Control optimization can reduce energy use by an additional 10-15%. These opportunities are currently underutilized because the processes of control optimization, implementation, and commissioning are not fully automated and do not interoperate with whole-building energy analysis. Lack of interoperability and automation increase manual effort, cost, and human error, limiting the deployment of high-performance control sequences.

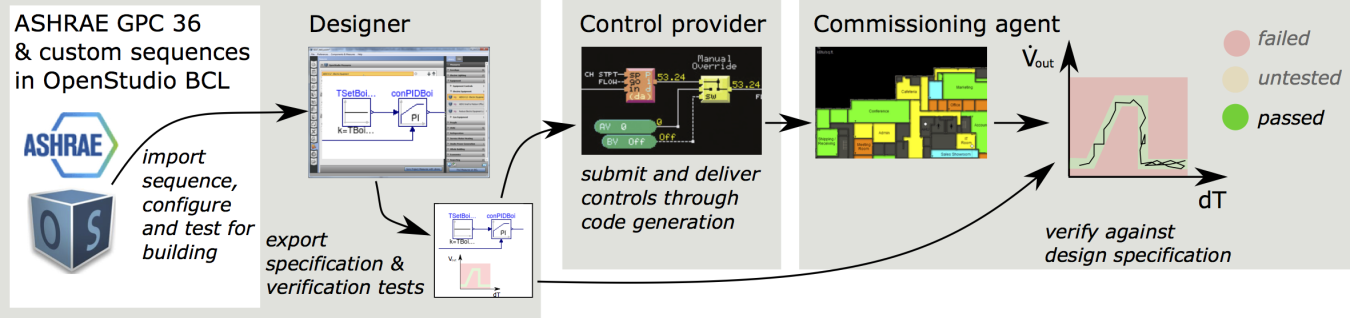

The OpenBuildingControl (OBC) project aims to address these digitization and interoperability gaps. BACnet and Haystack/BRICK already digitize and standardize the communication and semantic tagging aspects of the building control delivery process, respectively. OBC completes the chain by digitizing and standardizing the expression of control logic.

In the BENEFIT-2016 Open Building Control project, the project team defined a Control Description Language (CDL) that allows control sequences to be both simulated for performance evaluation and compiled to run directly on actual control product lines. CDL is a subset of the international standard simulation language Modelica. Modelica was chosen because its high level of abstraction supports automated verification and optimization, as well as translation to imperative control sequences implementation languages like C++ and Python. CDL can be simulated in a physically realistic way using the Modelica Buildings Library and Spawn. The team implemented a library of high-performance control sequences in CDL, including those defined in ASHRAE Guideline 36 “High Performance Sequence of Operations for HVAC Systems.” The team also implemented tools for testing and commissioning control sequences.

In this continuing project, the team will expand the library of best-in-class control sequences in CDL, develop a sequence selection and configuration tool, and work with control providers to develop translators from CDL to product lines.

Contacts

DOE Technology Manager: Amir Roth

Principal Investigator: Michael Wetter, LBNL