Lead Performer: Oak Ridge National Laboratory (ORNL) — Oak Ridge, TN Partner: GE Appliances a Haier Co. — Louisville, KY

April 10, 2019

Lead Performer: Oak Ridge National Laboratory (ORNL) — Oak Ridge, TN

Partner: GE Appliances a Haier Co. — Louisville, KY

DOE Total Funding: $900,000

FY19 DOE Funding: $400,000

Project Term: October 1, 2018 - July 12, 2020

Funding Type: Direct Funded

Project Objective

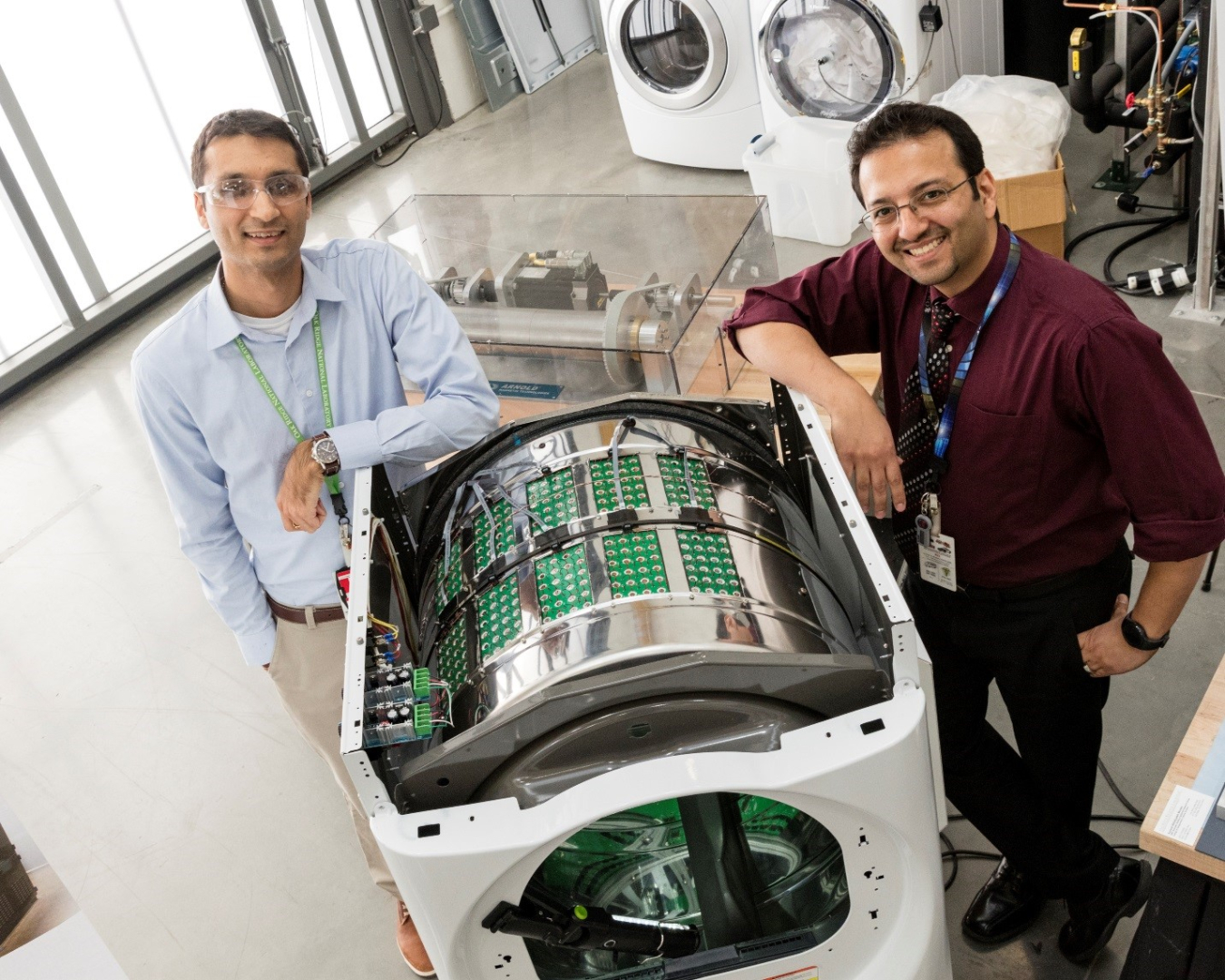

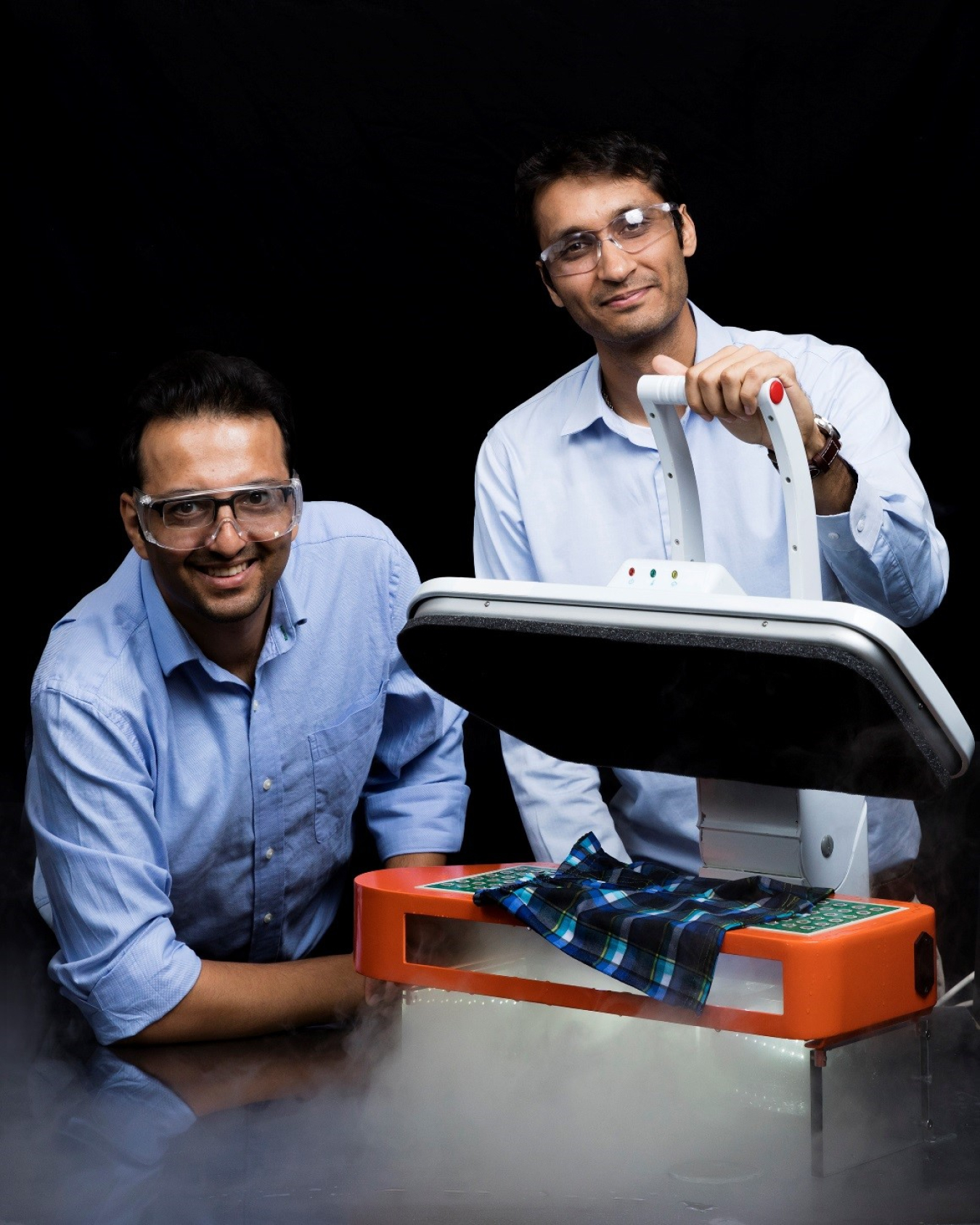

ORNL will work with their cooperative research and development agreement (CRADA) partner, GE Appliances, a Haier Company, to design, develop, and test a prototype clothes dryer that uses ultrasonic transducers to mechanically extract water from fabric. This project aims to develop a new clothes dryer that can increase the energy factor (EF) from 3.7 to 5.43 lb. per kWh without increasing the drying time by more than 20% over baseline units.

Unlike traditional dryers that rely on heat to evaporate the water out of clothes, the ultrasonic dryer uses a completely different process that is less energy-intensive. It works by using piezoelectric transducers, which are devices that convert electricity to vibration. When voltage is added, the transducers vibrate at a high frequency and turn the water into a mist as it is removed from the fabric.

Project Impact

Electric clothes dryers consume about 71 terawatt hours of energy annually and are one of the largest energy-consuming appliances in U.S. households. This new ultrasonic clothes dryer technology has the potential to reduce energy consumption by 0.4 quads. The project will help support the Building Technologies Office (BTO) goal to reduce building energy use intensity (EUI) by 30% in 2030 compared to 2010 levels.

Contacts

DOE Technology Manager: Antonio Bouza

Lead Performer: Viral Patel, Oak Ridge National Laboratory (ORNL)

Related Publications

- Eric Dupuis, Ayyoub M. Momen, Viral Patel, Shima Shahab, Electroelastic investigation of drying rate in the direct contact ultrasonic fabric dewatering process, Applied Energy, Vol. 235, 451-628, 28 October 2018.

- Viral K. Patel, Frederick Kyle Reed, Roger Kisner, Chang Peng, Saeed Moghaddam and Ayyoub Mehdizadeh Momen, Novel Experimental Study of Fabric Drying Using Direct-Contact Ultrasonic Vibration, Journal of Thermal Science and Engineering Applications, April 2019, Vol. 11, 021008-1.

- Dupuis, E., Momen, A. M., Patel, V. K., Shahab, S., “Ultrasonic Piezoelectric Atomizers: Electromechanical Modeling and Performance Testing,” Proc. ASME 2018 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, San Antonio, TX, USA, September 2018.

- Dupuis, E., Momen, A. M., Patel, V. K., Shahab, S., “Multiphysics modeling of mesh piezoelectric atomizers,” Proc. SPIE Conf. Smart Structures + Nondestructive Evaluation, Denver, CO, March 2018.

- Chang Peng, Ayyoub M. Momen, Saeed Moghaddam, An Energy-Efficient Method for Direct-Contact Ultrasonic Cloth Drying, Energy, Available online 12 July 2017, ISSN 0360-5442.

- Chang Peng, Saitej Ravi, Viral K. Patel, Ayyoub M. Momen, Saeed Moghaddam, Physics of direct-contact ultrasonic cloth drying process, Energy, Volume 125, 15 April 2017, Pages 498-508, ISSN 0360-5442

Patent

Ayyoub M. Momen, Gluesenkamp, K.R., Vineyard, E.A., Kisner, R. (2016). Dryer using high-frequency vibration. PCT/US16/30885. Filed May 5, 2016.

Licensing

Ultrasonic Technology Solutions, LLC exclusively licensed the technology from ORNL in the industrial and commercial fields of use.