Lead Performer: Xergy Inc. – Seaford, DE Partners: -- University of Delaware - Newark, DE -- Oak Ridge National Laboratory - Oak Ridge, TN

September 16, 2015Lead Performer: Xergy Inc. – Seaford, DE

Partners:

-- University of Delaware - Newark, DE

-- Oak Ridge National Laboratory - Oak Ridge, TN

DOE Total Funding: $1.7 million

Cost Share: $300,000

Project Term: July 1, 2015 – May 31, 2017

Funding Opportunity: Building Energy Efficiency Frontiers and Innovation Technologies (BENEFIT) – 2015

PROJECT OBJECTIVE

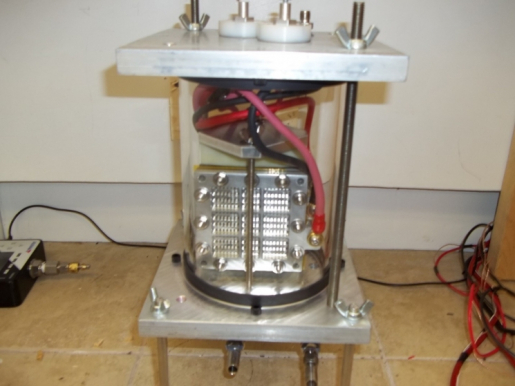

Our goal is to develop the most efficient, noiseless, and most environmentally friendly electrochemical compressor (ECC) to replace mechanical compressors for use in building heating, ventilation and air-conditioning (HVAC) systems. Xergy’s ECC technology holds the promise of being able to compress gases isentropically with maximum exergetic efficiency – better than any alternative method of gas compression.

The overall objective of the proposed work is to develop and build a scalable 5,000 BTU/hr. ECC-based air conditioning system operating with a rated Coefficient of Performance (COP) of 4.5 in cooling applications with a price premium of $70 installed per kBtu/hr. The proposed ECC system will employ an environmentally benign refrigerant, water, as the working fluid. ECC will be combined with an energy recovery module for improved management of latent and sensible heat loads to develop a novel AC system with unprecedented efficiency.

ECC technology will be studied and engineered to optimize the efficiency and cost effectiveness of ECC air-conditioning units. This will be accomplished by investigating, choosing, and testing new system configurations and components. In addition, ECC technology will be combined and optimized with novel evaporative desiccants or membrane drying system to separate the sensible and latent cooling loads. The output from the proposed program will yield a cost-effective HVAC cooling unit, which when produced at high volume, will give a five-year or better payback period.

PROJECT IMPACT

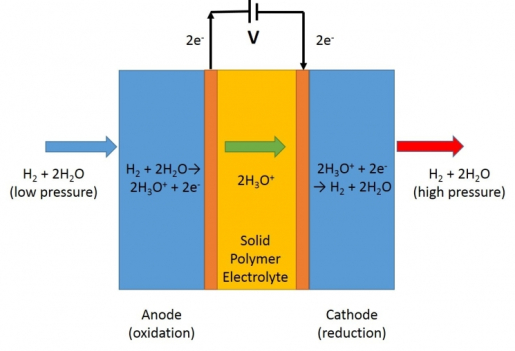

Water is environmentally benign and is an excellent refrigeration working fluid due to its high enthalpy of vaporization, but it is difficult to transport and compress with typical mechanical compressors. Electrochemical compression technology enables the use of water as a refrigerant for heat pump cycles by adapting technology originally created for hydrogen fuel cells. Electrochemical compressors (a) are more efficient (i.e. have an inherently high COP) than conventional compressors, (b) are motorless and therefore reliable and noiseless, (c) use non-HFC refrigerants and therefore have a lower global warming potential, (d) are modular and scalable, (e) can operate very efficiently at partial loads, and (f) can be designed to fit different form factors.

CONTACTS

DOE Technology Manager: Tony Bouza

Lead Performer: Brian Kienitz, Ph.D., Xergy Inc.