Lead Performer: InnoSense, LLC- Torrance, CA

DOE Total Funding: $206,499

Project Term: June 29, 2020 – March 28, 2021

Funding Type: Small Business Innovation Research (SBIR) Project Grant #: DE-SC0020739 (Phase I)

Project Objective

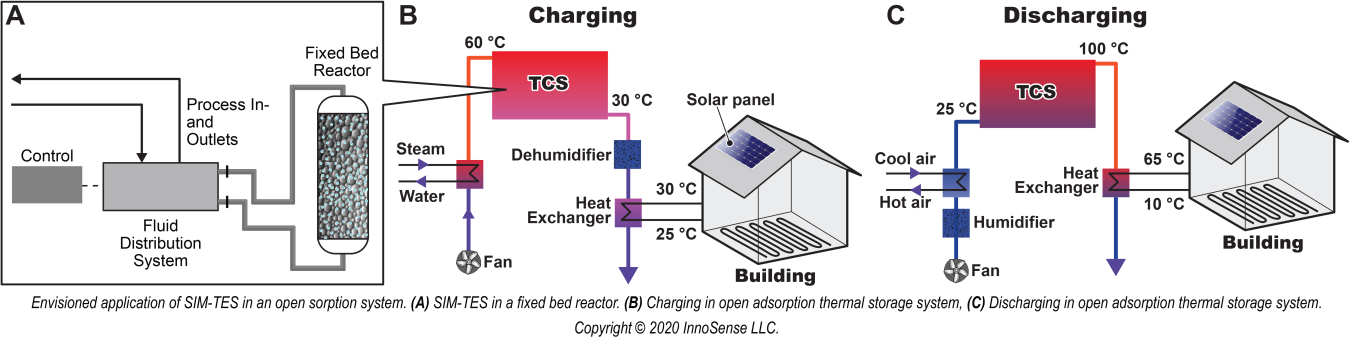

InnoSense is developing a Salt Impregnated Matrix composite for Thermochemical Energy Storage (SIM-TES™) that employs anhydrous and hydrated salts as a thermochemical material (TCM). The salts impregnated in a highly porous host matrix, along with a highly conductive additive, will offer a form-stable composite material for applications in building energy storage. SIM-TES will address the limitations of prior TCMs such as high regeneration temperatures, recyclability and hydrothermal instability at operating conditions. SIM-TES offers the following beneficial features:

- A high porosity host matrix that allows impregnation of more salt (>60%) with a large effective area.

- Reduced pressure drop promoting even vapor feed distribution.

- A high conductivity additive to enhance heat transfer and minimize undesirable thermal gradients.

- A composite that achieves low regeneration temperatures around 50 °C.

Further, both the host matrix and salt will be active TCMs with capability to function over a range of temperatures, thus enhancing the system efficiency of the composite SIM-TES.

The performance of SIM-TES material is determined by its inherent properties. SIM-TES will be characterized by pore structure, specific surface area, and hygrothermal properties, and will be compared with bare TCM (inorganic salt). The morphology, microstructure and chemical compatibility of SIM-TES will also be determined. In addition, ISL will develop a laboratory setup to evaluate performance by determining the regeneration temperature and energy density of the composite. The cyclability of SIM-TES will be assessed in a laboratory setup to understand material degradation and reusability over time. Further, technoeconomic analysis will be performed from the earliest stages of the project. Tradeoffs between performance and material costs will be assessed to inform on the efficacy of the thermochemical energy system for further development in Phase II.

Project Impact

The detailed characterization of SIM-TES and the laboratory setup to test the composite TES will provide a proof of concept demonstration and viability of the approach for building energy applications. Phase I performance metrics for the composite SIM-TES will be based on evaluation of the regeneration temperature, hydrothermal stability, recycling ability, thermal conductivity and energy density. In Phase II, we will test SIM-TES in both open and closed sorption prototypes and conduct a more rigorous technoeconomic analysis for benchmarking the SIM-TES system. Further, Phase I results will provide a basis to expand into additional aspects of the TES process in Phase II.

TES technology will be useful to (1) handle fluctuations in energy demands and efficiently use fluctuating production sources such as renewables, (2) increase energy grid safety, and (3) improve overall system efficiency. Developing the composite SIM-TES – a nontoxic, noncorrosive, nonflammable, low-cost sorbent material with high energy density – will address the existing problems of high regeneration temperatures, recyclability, and hydrothermal instability at operating conditions in order to facilitate a commercially feasible system.

Contacts

DOE Technology Manager: Sven Mumme

Lead Performer: Harini Madakashira, InnoSense LLC