RSS

The Bioenergy Technologies Office (BETO) blog posts are a great source to learn about the progress BETO is making toward its goals.

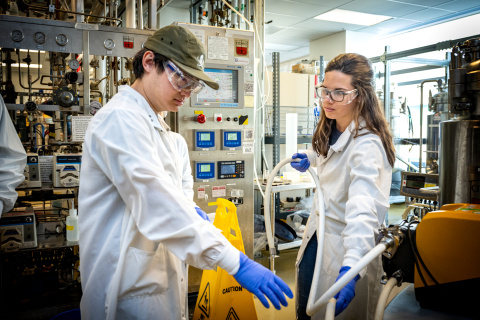

As a recent college graduate, Javier Santana was working in the petrochemical industry when he decided to make a career change. Seeking more opportunities for innovation, he turned to biomanufacturing — a growing industry that uses microbes to create chemicals, fuels, materials, and food products.

A new study from a U.S. Department of Energy (DOE) Bioenergy Technologies Office (BETO) funded startup, Algenesis Corporation, has demonstrated the ability to formulate high quality polyurethane products, including waterproof fabrics and cell phone cases, that generate no persistent microplastics. By utilizing some clever chemistry and sourcing oil from algae instead of petroleum, they can produce polyurethane plastics that biodegrade naturally in the environment.

As seen in two U.S. Department of Energy Bioenergy Technologies Office-funded NREL studies, techno-economic analysis (TEA) and life cycle assessment (LCA) can be powerful tools to help stakeholders realize the best fiscal and environmental returns.

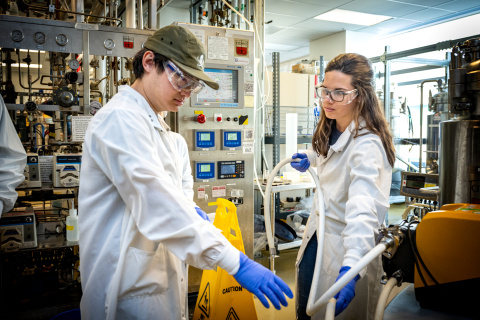

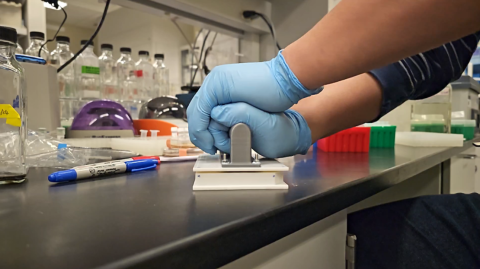

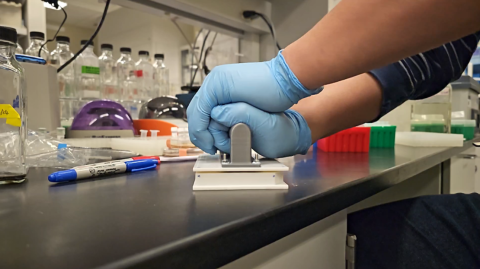

Researchers sometimes genetically engineer microorganisms—such as fungi—to convert renewable feedstock materials into useful biofuel or biochemical products. Polymerase chain reaction (PCR), which allows researchers to quickly amplify DNA sequences for analysis, is one of the most essential tools in this process. When working to synthesize biofuels using fungi, PCR is particularly important for evaluating various strains of mutated fungi.

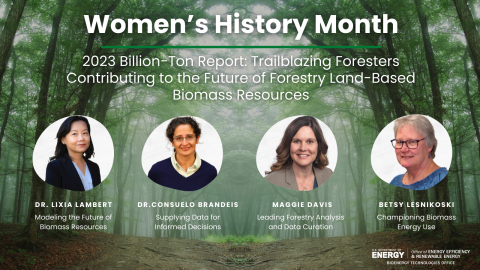

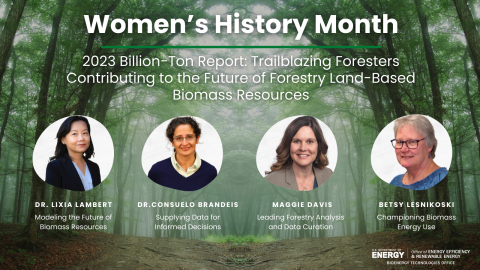

The U.S. Department of Energy (DOE) recently released a robust analysis, the 2023 Billion-Ton Report (BT23), showcasing how America could viably triple its production of biomass to more than 1 billion tons per year while still meeting the projected demand for food, feed, fiber, conventional forest products, and exports. The impact of this comprehensive analysis is far-reaching and DOE Bioenergy Technologies Office (BETO) Technology Manager, Dr. Mark Elless, managed the development of BT23 which was led by Oak Ridge National Laboratory.

On March 15, 2024, the U.S. Department of Energy (DOE) released the 2023 Billion-Ton Report (BT23), which shows that the United States could triple its production of biomass to more than 1 billion tons per year.

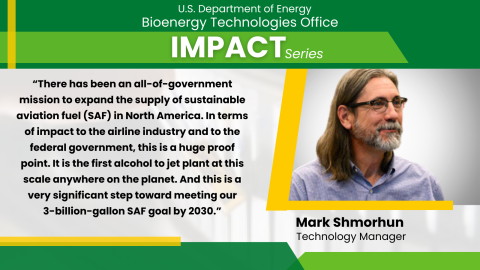

In January 2024, the first commercial production facility for converting ethanol into SAF opened in Soperton, Georgia. Supported by DOE’s Bioenergy Technology Office (BETO), LanzaJet’s Freedom Pines Fuel Facility will produce nine million gallons of SAF and one million gallons of renewable diesel in its first year of operations and will provide significant benefits for the local economy.

Kevin Craig retired in December 2023 after nearly two decades of service to the U.S. Department of Energy (DOE) Bioenergy Technologies Office (BETO).

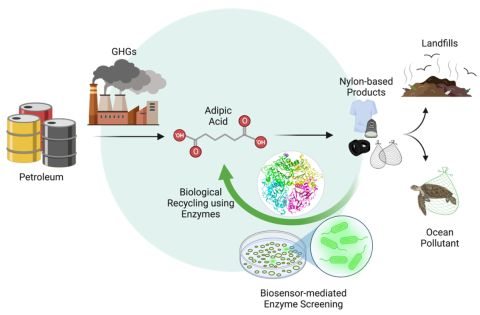

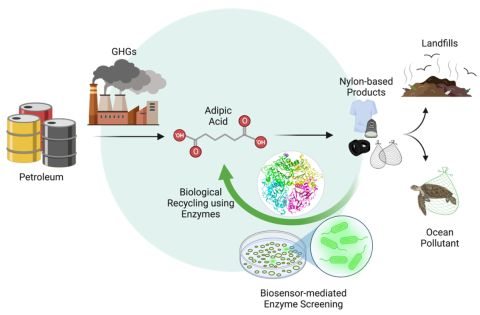

Scientists at Los Alamos National Laboratory (LANL) have developed biosensing technology that can help address the problem of plastic waste, specifically nylon-based waste such as textiles, carpets, tires, and fishing nets. These and other products are...

More ethanol, fewer emissions, land with multiple purposes—there are several advantages of using renewable electricity to increase the carbon efficiency of biorefineries.