At the Consortium for Computational Physics and Chemistry (CCPC), researchers study fluidized bed reactors used for converting biomass into oil via pyrolysis.

In the reactor, biomass particles flow through a bubbling sand bed that is kept in a moving or “fluidized” state by the flow of an inert process gas like steam or nitrogen; thus, fluidized bed reactors are also known as “bubbling” bed reactors. The biomass particles heat up quickly as they interact in the hot bubbling sand bed and volatilize to release hydrocarbons (oil or tar), leaving char (mostly carbon) and other light gas products.

As the oil vapors, char, and light gases exit the reactor, the char is separated from the oil vapors and other gases, which flow to other reactors for further processing. The char can be put back in the earth for soil remediation to sequester carbon and even improve plant yield in agriculture.

CCPC Computational Fluid Dynamics Modeling

The CCPC captures the complex hydrodynamics of the process with computational fluid dynamics (CFD) models that track the flow of millions of sand and biomass particles as well as the light gas products and oil vapors flowing through the reactor.

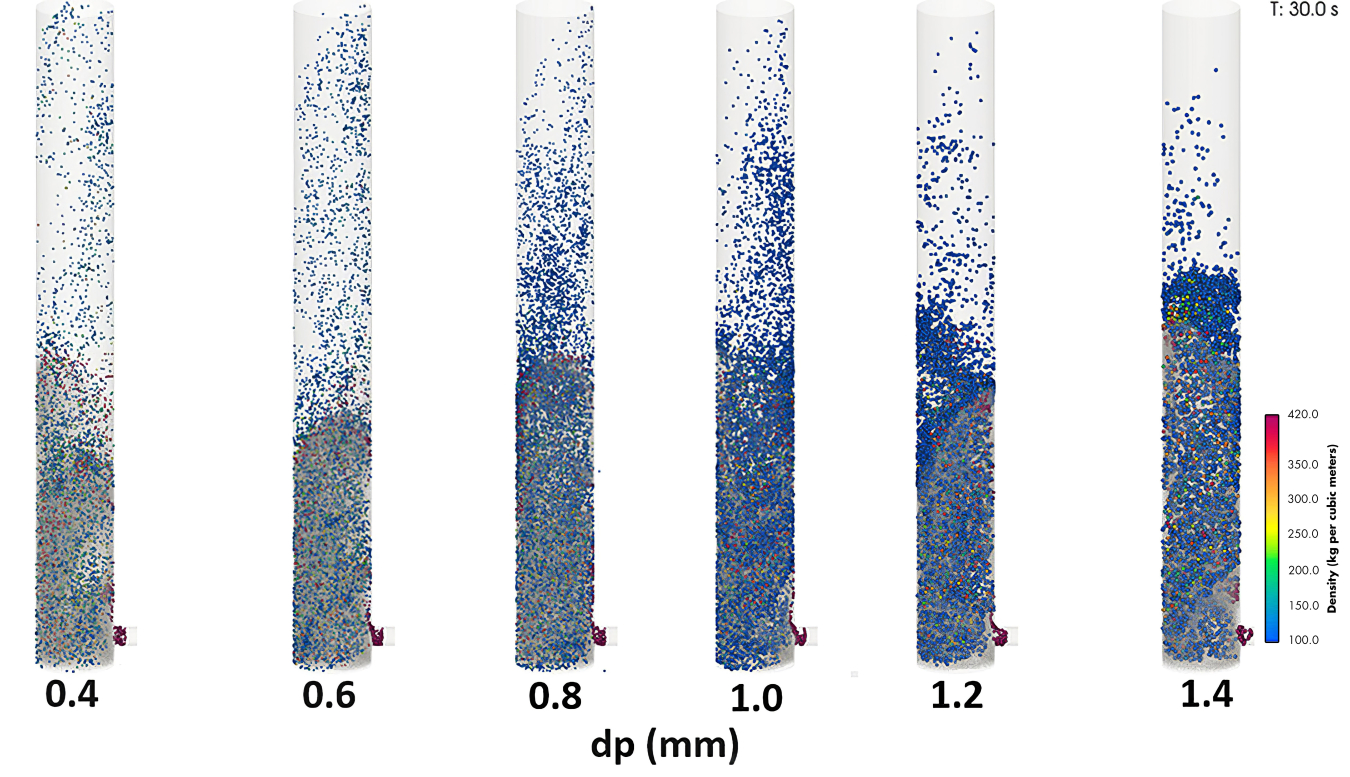

Due to the complexity of tracking the physics and chemistry of the millions of particles and chemical reactions, CFD model simulations are typically performed on high-performance computers that leverage the combined power of many processors or central processing units. In this manner, many simulation cases (Figure 1) can be performed in a reasonable time.

Figure 1: CFD model simulations of the fast pyrolysis of biomass in a fluidized bed reactor. The gray particles represent the sand bed in the reactor, and the colored particles represent biomass particles of a different density as the fresh biomass (red color, high density) converts to char (blue color, low density). The simulations were performed using the same process gas flow rate but different biomass particle diameters (dp) of 0.4, 0.6, 0.8, 1.0, 1.2, and 1.4 mm. Image courtesy of Bill Rogers, National Energy Technology Laboratory.

The models enable calculation of the residence time of the biomass particles in the reactor, which critically affects the yield of oil from the biomass in fast pyrolysis. If biomass particles leave the reactor too soon, pyrolysis does not fully complete leaving unextracted hydrocarbons in the char product; in contrast, if residence times in the reactor are too long, the oil vapor product can be consumed by catalytic reactions with ash elements like potassium or iron that remain after pyrolysis occurs.

Since residence times are extremely difficult to measure experimentally, CCPC models provide an excellent means to optimize the operation of the reactor for the conversion of widely variable biomass feedstocks. This will help achieve the correct residence time and maximum yield of oil vapors that can be upgraded to transportation fuels.