Bioprose Blog: NREL researchers showed several cost-saving benefits by using a common pulp and paper industry method to breakdown biomass.

May 21, 2020

Author: Zia Abdullah, Laboratory Program Manager, National Renewable Energy Laboratory

Read Zia's bio ►

Meet the other bloggers ►

Return to Bioprose blog ►

Bioprose Blog

Achieves high sugar yields with low enzyme loadings

Deconstructing Biomass with a Common Pulp and Paper Industry Method

Ozone treatment (aka "ozonolysis") of lignocellulose pulp is a widely practiced method for bleaching in the commercial-scale pulp and paper industry (greater than 1,000 tons/day). National Renewable Energy Laboratory (NREL) researchers Xiaowen Chen and Melvin Tucker experimented with the ozonolysis method to see how well it could break down the lignin in corn stover. Results showed several cost-saving benefits:

- Decreased enzyme usage and chemical/power requirements during biomass deconstruction through NREL-developed deacetylation and mechanical refining (DMR). DMR is a biochemical conversion process to help overcome lignocellulosic biomass' natural resistance to being broken down (aka "recalcitrance").

- Increased enzymatic hydrolysis sugar yields, which means increased drop-in fuel production.

Researchers at NREL carefully monitor the ozone concentration in the pretreatment reactor. Photo credit: Alexa Schwartz.

NREL's Method

To test the hypothesis, NREL researchers used an ambient temperature ozonolysis reactor to ozone-treat deacetylated corn stover prior to mechanical refining. NREL then performed mechanical refining and high-solids enzymatic hydrolysis to produce fermentable sugars.

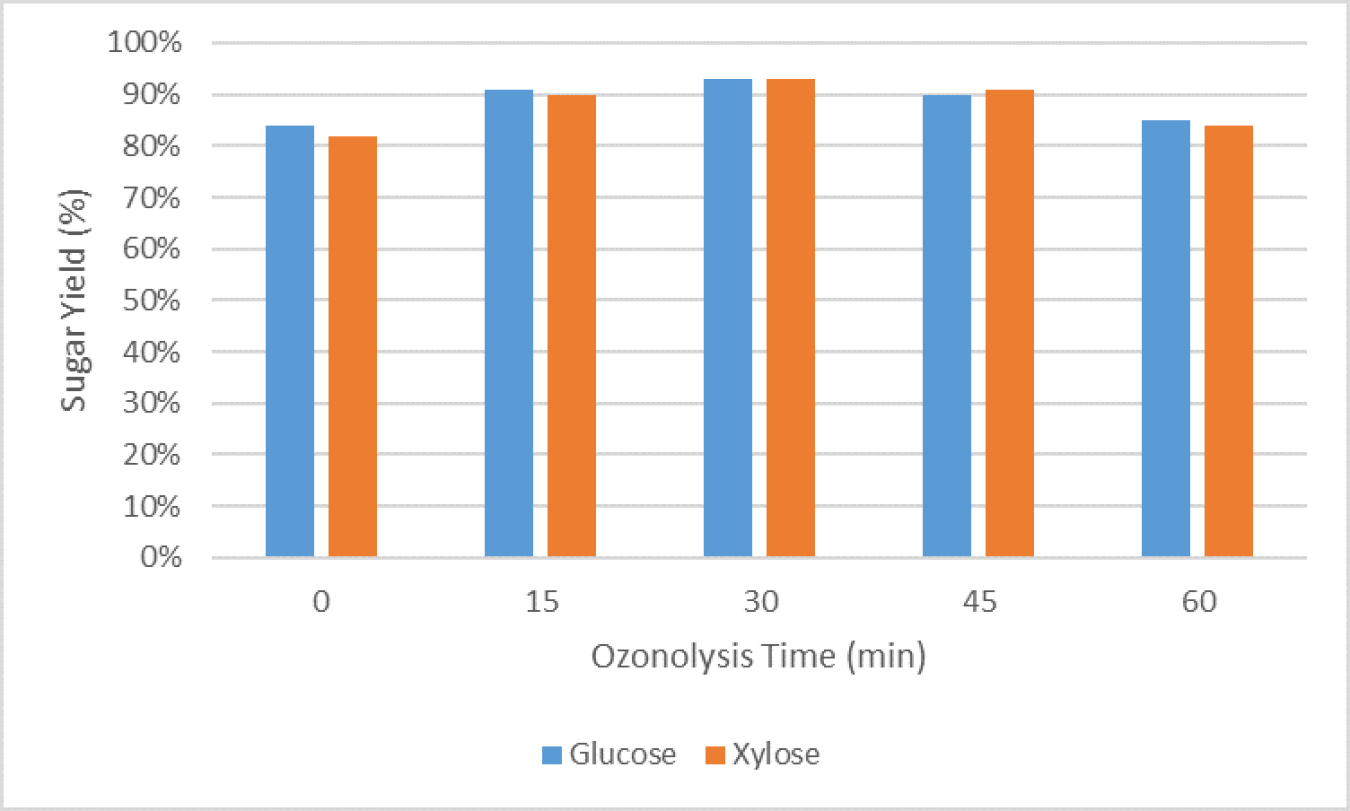

With this new, ozonolysis-assisted approach, NREL achieved monomeric glucose and xylose yields greater than 90% at a total enzyme loading of 12 milligrams/gram (mg/g) (Figure 1). Even with a reduced enzyme loading of 10 mg/g, monomeric glucose and xylose yields are 88% and 90%. Without the ozonolysis-assisted approach, the monomeric glucose and xylose yields were 10% lower. Increased yields of sugar can reduce the cost of biofuel or bioproduct production.

Figure 1. NREL scientists discovered that a total enzyme loading of 12 mg/g in an ozonolysis reactor achieves glucose and xylose yields greater than 90% particularly after 30 minutes of ozonolysis time. Illustration by NREL.

The Impact of Ozonolysis for Biomass Deconstruction

Ozonolysis represents a potential near-term solution to achieving targeted enzymatic hydrolysis sugar yields using existing commercial enzyme preparations by adding a processing step to improve the hydrolysis of highly recalcitrant feedstocks. Preliminary techno-economic analyses by NREL indicate that the performance advantages for the use of ozonolysis outweigh its costs and result in lower prices for sugar and downstream upgrading.

Dr. Zia Abdullah

Dr. Zia Abdullah is laboratory program manager for the National Laboratory of the Rockies' (NLR) Bioenergy Technologies Office program.

Zia has extensive experience and accomplishments in thermochemically and biochemically converting biomass to fuels and chemicals. His experience includes more than 25 years of industrial research and development in biomass conversion, as well as problem solving, new product development, business development, and project management.

Prior to joining NLR, Zia was chief technology officer at Versa Renewables LLC, where he developed and commercialized biomass pyrolysis and biopolyol technologies. Before Versa, Zia served as one of the Battelle Memorial Institute’s 11 fellows, leading the development of technology and commercial application for fuels, chemicals, and materials from the thermochemical and biochemical conversion of biomass. Prior to working at Battelle, Zia was a research advisor (fellow) at Weyerhaeuser Company, where he worked on challenges related to manufacturing and biomass valorization.

Meet our other bloggers ►

Return to Bioprose blog ►