Many challenges facing today’s biorefineries stem from the fact that the physical, chemical, and mechanical characteristics of biomass can vary widely. The Feedstock-Conversion Interface Consortium (FCIC) brings together leading researchers to tackle these issues.

The FCIC is a Bioenergy Technologies Office-funded collaboration of industry advisors and researchers at nine U.S. Department of Energy (DOE) national laboratories. The FCIC uses first-principles-based science to de-risk biorefinery scale-up and deployment by understanding, quantifying, and mitigating the impacts of feedstock variability on bioconversion processes.

First-Principles Approach to Understand Feedstock Variability

FCIC researchers at NREL load feedstock into pilot plant reactors during a 48-hour hot test.

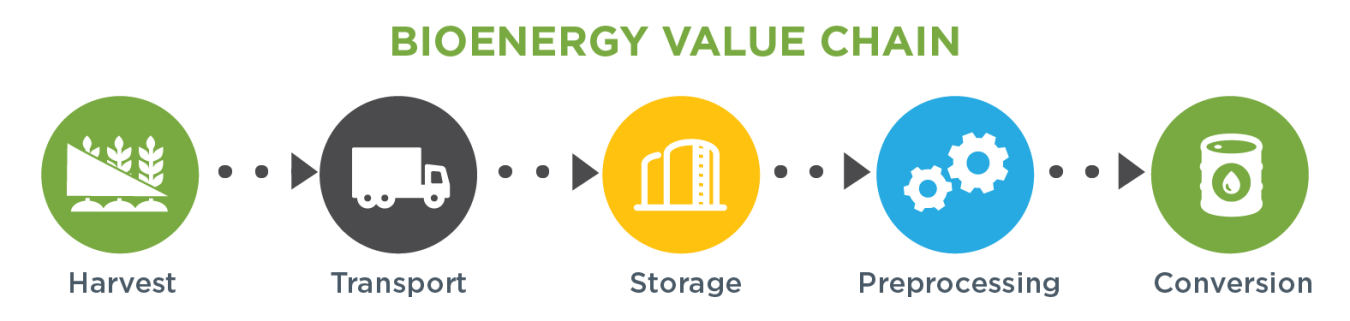

The physical, chemical, and mechanical characteristics of biomass and waste feedstocks differ from more familiar agricultural commodities, like grain or barley. In addition, they can vary widely among different biomass, among different anatomical fractions within a single biomass type, and can change over time. Because of this, the empirical knowledge regarding the harvest, transport, storage, and conversion developed for agricultural commodities has not proven helpful to the emerging biorefinery industry.

The FCIC is organized into eight tasks that span the bioenergy value chain. By linking these processes through research, the FCIC will fully understand how variability in one operation affects other operations and can address upstream and downstream needs and interactions.

Team

The FCIC is led by three DOE technology managers, laboratory relationship managers from each participating lab, a principal investigator, and a project manager. Learn more about the FCIC leadership team.

The FCIC consists of nine DOE national laboratories and an Industry Advisory Board, as well as industry, university, and other DOE consortia partners. Learn more about the FCIC partners.

Research Results and Data

The FCIC utilizes a LabKey-based FCIC Bioenergy Data Hub to track and store data and results. Database access is currently restricted to consortium members. Access can be requested by contacting the FCIC.

FCIC Webinars

Watch past FCIC webinars to learn more about the consortium, select research projects and insights, tools, and capabilities.

Contact

Questions about the consortium? Contact the FCIC.