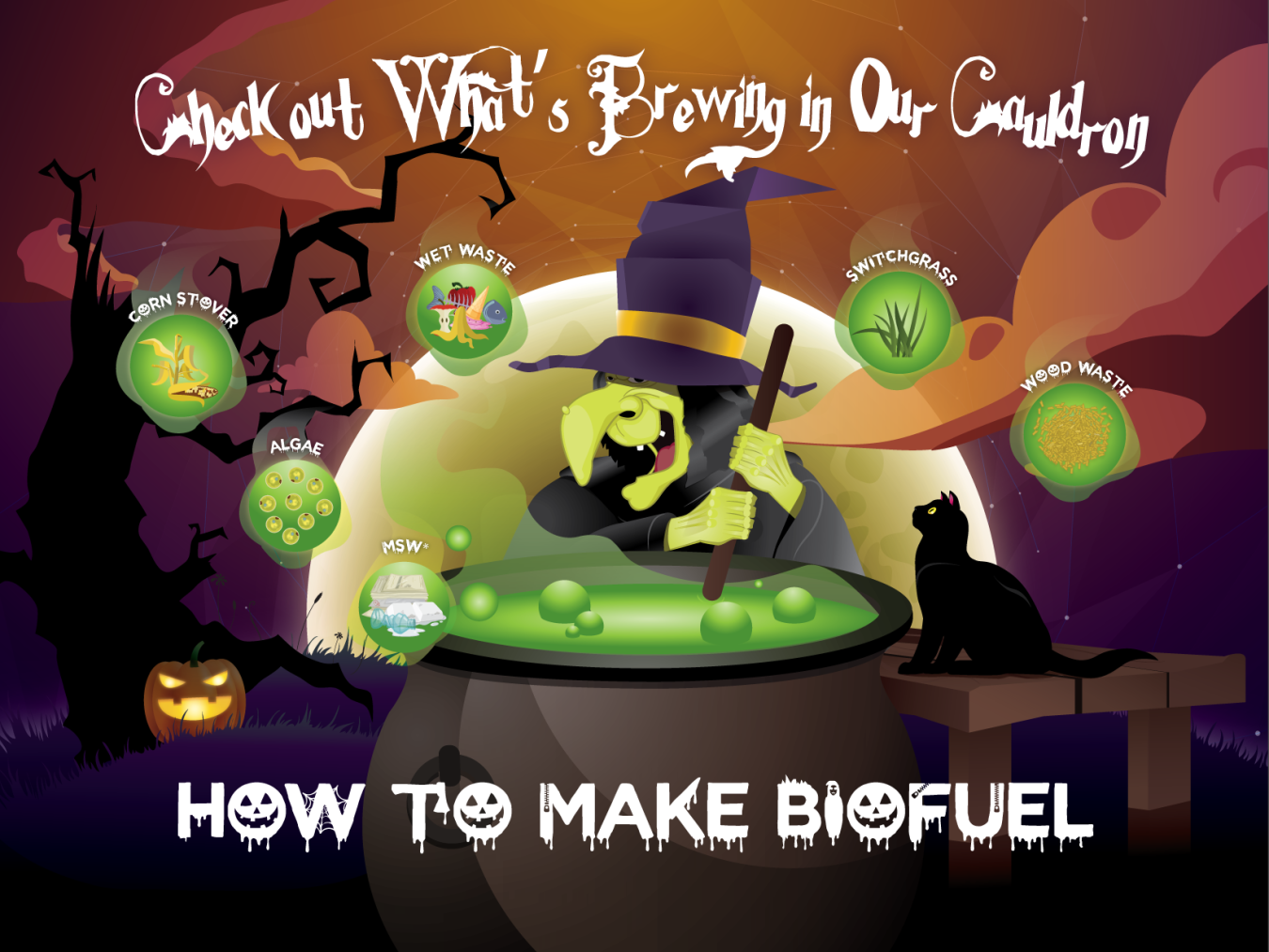

Boo! It’s Halloween and the Bioenergy Technologies Office's cauldron is full of biofuel! Here's how it works.

Office of Critical Minerals and Energy Innovation

October 31, 2024

Biofuels are liquid transportation fuels made from renewable, organic matter called biomass, which includes corn stover, wet waste, algae, municipal solid waste (MSW), dedicated bioenergy crops like switchgrass, and wood waste.

Boo! It's Halloween, and here at the U.S. Department of Energy's (DOE's) Bioenergy Technologies Office (BETO), our cauldrons are brewing with biofuel!

Biofuels are liquid transportation fuels made from renewable, organic matter called biomass, which can be used to power planes, trains, and even ships!

Check out our "recipe" for how to make biofuel:

Ingredients

- Biomass

- Catalyst (enzymes)

- Extreme heat and pressure or microbes

Supplies

- Biomass processing facility

- Safety goggles

Instructions

Step 1

The first step to making efficient and affordable biofuel is to gather some biomass.

So what is biomass exactly?

It’s a versatile and abundant renewable energy resource derived from organic matter that can luckily be found almost anywhere―food waste at the garbage dump, plant material (stalks, cobs, and stems) left over from harvested food crops, and what we flush down the toilet.

Watch: See how sewage can be converted into biofuels.

There’s even a good chance you’re using biomass right now, as it can also be converted into everyday products (also known as bioproducts) like cosmetics, detergents, and plastics.

Bottom line: There is a lot of it. The United States has the capacity to sustainably produce more than 1 billion tons of biomass annually, producing an estimated 60 billion gallons of low greenhouse gas liquid fuels, while still meeting the projected demand for food, feed, fiber, conventional forest products, and exports.

Step 2

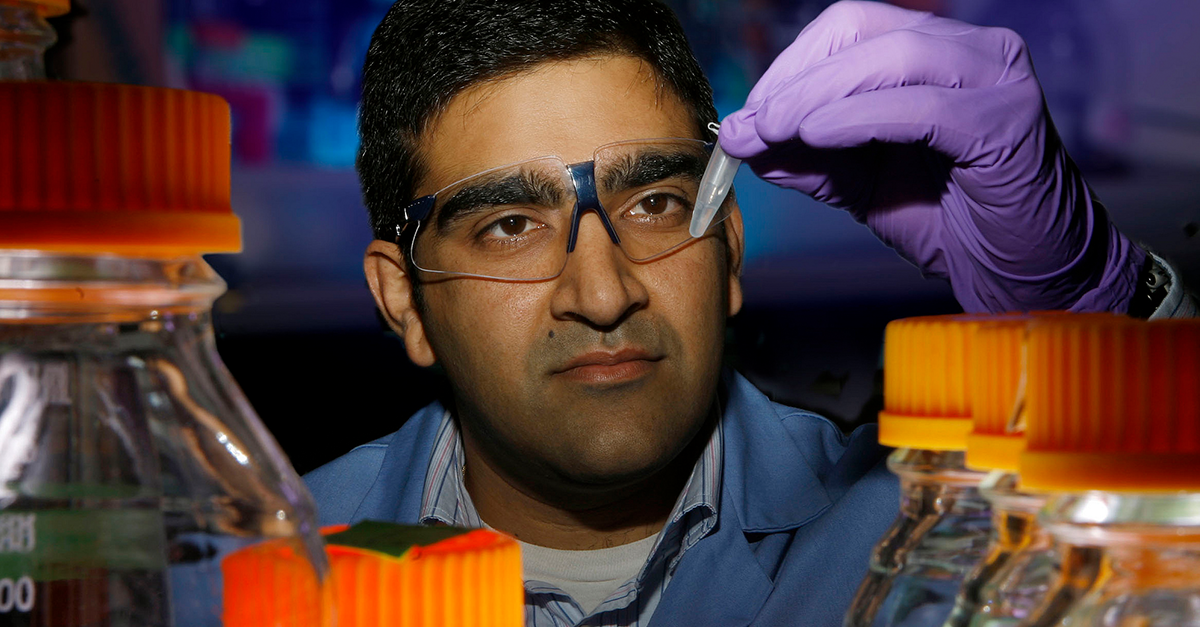

Next, a research scientist breaks down the biomass into an intermediary, like a gas or sugar, at a biomass processing facility. This is typically done in two ways:

- Heat solid biomass at high temperatures and pressures until it liquefies or forms a gas. Then, add in a catalyst—one of the most important tools in a chemical engineer’s toolbox—to turn it into a finished fuel product.

- Extract plant sugars from biomass, which are then fed to microbes. As the microbes digest the sugar, they produce fuel as a waste product.

Step 3

Lower the cost.

BETO is constantly working to perfect the biofuel recipe. Several recent breakthroughs were made to advance biofuel production, including using artificial intelligence to simplify the biomass process and a new technology that could reduce the minimum fuel selling price of biofuel by 12%.

These breakthroughs are just a few examples of how BETO is helping to make biofuel production more efficient and cost-effective, bringing BETO closer to reaching its modeled mature price of biofuel of $3/gasoline gallon equivalent.

This article was originally published in October 2017 and updated in October 2024.

Watch: Learn more about biofuels.

Learn more about the Bioenergy Technologies Office