Reduction of Burner NOx Production with Premixed Combustion

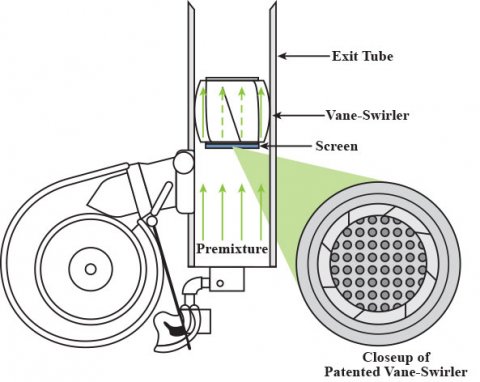

Industries that are dependent on combustion processes are faced with more stringent environmental regulations to reduce NOx emissions. Some states require NOx emissions reductions as great as 90% for chemical and refining industries. The recently developed M-PAKT™ Ultra-Low NOx Burner uses lean premixed combustion gases and low swirl flow of combustion gases to achieve NOx emissions levels <10 ppm (an NOx reduction of 80% to 90%).

The research for this technology originated at Lawrence Berkeley National Laboratory with funding from the DOE Office of Science Experimental Program and AMO. This new burner's distinct characteristic is a detached flame that is lifted above the burner, providing the capability for more complete combustion with less emissions. This burner concept can be applied to a wide range of combustion systems including furnace and boiler applications, gas turbines, and liquid process heaters for the chemical and refining industries. The burner can be operated with natural gas, biomass gas, and pre-vaporized liquid fuels. The burner is scalable and simple in design with no need for costly materials for manufacturing and installation. Maxon Corporation has licensed the technology for industrial process heaters used in many industrial baking and drying ovens. Applications have also been successfully tested in smaller-diameter domestic heater units.

Overview

- Developed by LBNL with two patents issued.

- Installed in the U.S. and overseas.

- Technology licensed to Maxon Corporation and sold as the M-PAKT burner.

- Over 1408 burners estimated to reduce NOx by over 1.550 million pounds in 2011.

Applications

Can be used on a wide range of combustion systems: furnaces and boilers, chemical and refining industry process heaters, and gas turbines.

Capabilities

Reduces thermal NOx in the combustion zone.

Benefits

Adaptability

Burns different gaseous fuel types and blends. Can be scaled to different sizes of units and adapted to different orientations and sizes of various flue configurations.

Low Cost

Offers low cost for manufacturing compared with traditional low NOx solutions because the components are simple and are made from conventional materials.

Pollution Reduction and Energy Efficiency

Typically reduces NOx to less than 10 ppm without compromising energy efficiency.

Contact Information

Curtis Taylor

(765) 254-1141

ctaylor@maxoncorp.com

Maxon Corporation