Photo

Caption

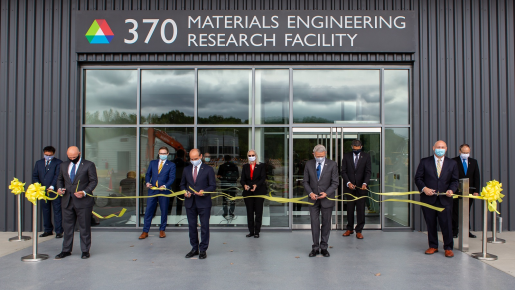

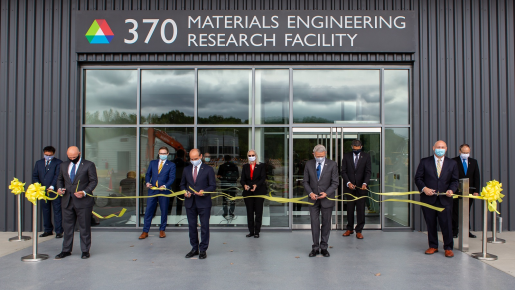

Deputy Secretary of Energy, Mark Menezes, and Deputy Assistant Secretary Alex Fitzsimmons cut the ribbon on the expanded Materials Engineering Research Facility at Argonne National Laboratory.

Photo

Caption

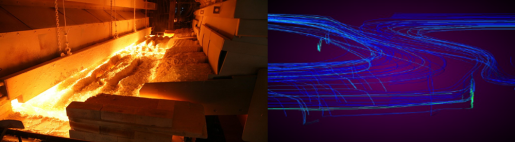

Glass manufacturers use high-performance computing to enable machine learning tools that can detect and correct for variations in glass furnaces in real-time. Photo Courtesy: Vitro Glass / LLNL

Photo

Caption

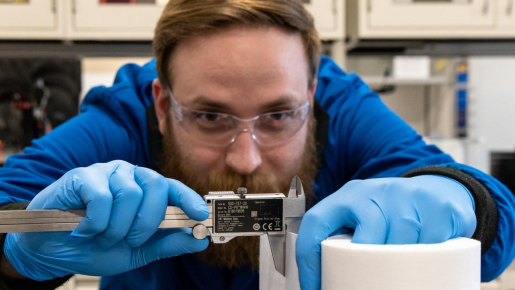

An engineer monitors a feed control system for a new, energy efficient pilot process for producing ethylene, one of the most energy-intensive and commonly manufactured chemicals. Photo Courtesy: EcoCatalytic

Photo

Caption

More than 1,400 new robots are a part of the body shop at General Motors’ Arlington Assembly plant. This facility was among the 25 GM plants that achieved DOE’s 50001 Ready status for implementing energy management systems. Photo Courtesy: GM Archive Photo

Photo

Caption

The Enhanced Preparation for Intelligent Cybermanufacturing Systems (EPICS) program at Georgia Tech prototypes a face shield frame in response to COVID-19. EPICS prepares students for the next-generation of manufacturing careers. Photo Courtesy: Georgia Tech

Photo

Caption

Carbon Fiber Technology Facility Director Merlin Theodore holds material meeting N95 specifications produced at the facility. The team developed process parameters for manufacturers to recalibrate melt-blown machines to address shortages. Photo Courtesy: ORNL

Photo

Caption

Researchers at the Oak Ridge National Laboratory Manufacturing Demonstration Facility use metal additive manufacturing to create toolsets for reusable masks in response to COVID-19. Photo Courtesy: ORNL

Photo

Caption

A student in the Industrial Assessment Center (IAC) program performs an energy assessment. The IACs, located at 31 universities around the country, provide small- and medium-sized manufacturers with recommendations to identify annual savings opportunities.

Photo

Caption

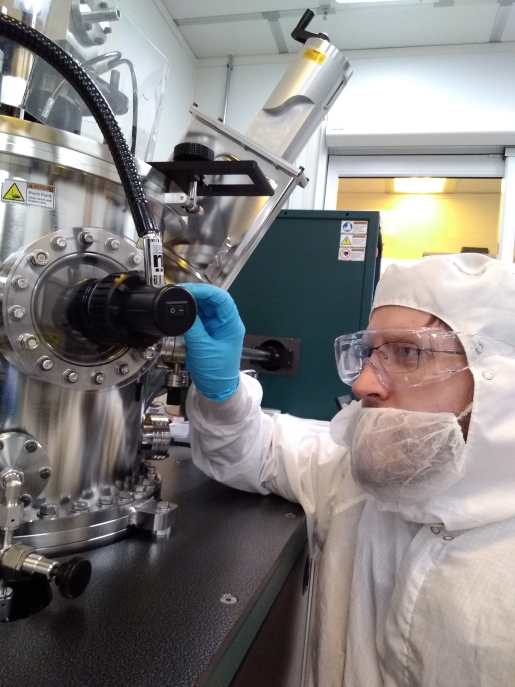

Kevin O’Connor conducts R&D for technology that will improve energy storage performance and enable more compact devices with higher reliability through DOE’s Lab-Embedded Entrepreneurship Program node at Argonne National Laboratory. Photo Courtesy: ANL

Photo

Caption

NEW Water achieved its Better Plants Challenge energy intensity reduction goal by implementing their Resource Recovery and Electrical Energy project, which replaced an existing solids handling facility and installing two anaerobic digesters to capture methane gas and produce electricity.

Photo

Caption

Ford Motor Company won a 2020 Better Practice Award for innovative energy efficiency actions at their Dearborn Research and Engineering Campus Central Energy Plant, including real-time 3D modeling of energy systems.

Photo

Caption

Undergraduate research assistant with equipment data visible on augmented reality Smart Glasses works on the Cyber-Physical Lab testbed at West Virginia University’s Smart Manufacturing Lab. Photo Courtesy: CESMII and Paige Nesbit

Photo

Caption

University of Tennessee (UT) Assistant Professor of Architecture Maged Guerguis, left, and IACMI Institute Chief Technology Officer Uday Vaidya display the UT Shield in the IACMI-supported Fibers and Composites Manufacturing Facility on the UT campus in Knoxville. Photo Courtesy: IACMI

Photo

Caption

Advanced Manufacturing Office Deputy Director Valri Lightner speaks with students and staff from the University of Illinois at Chicago at the school’s combined heat and power plant, which efficiently produces thermal energy and electricity for the campus. Photo Courtesy: University of Illinois, Chicago

Photo

Caption

Researchers at DOE’s Carbon Fiber Technology Facility at Oak Ridge National Laboratory worked with Dr. Peter Tsai, N95 material inventor, and used melt blowing to produce the filter that lines face masks and protects healthcare workers against COVID-19. Photo Courtesy: MDF

Photo

Caption

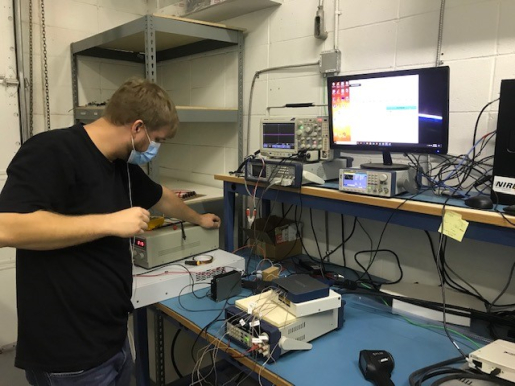

A graduate student at Texas Tech calibrates a high current wide bandgap module test apparatus. By establishing an independent third party testing facility with funding from PowerAmerica, Texas Tech University and Group NIRE are working with companies to demonstrate long-term performance and enhancing end-user confidence in the reliability of wide bandgap devices. Photo Courtesy: PowerAmerica

Photo

Caption

Project Manager Will Rice oversees the McAlpine Creek Wastewater Management 1 MW biogas-fueled engine-based combined heat and power (CHP) system, developed with technical support by the Southeast CHP Technical Assistance Partnership.

Photo

Caption

Ikenna Nlebedim loads discarded hard disk drives into a specialized shredder that helps the Critical Materials Institute improve its patented, acid-free dissolution process that recovers high purity REE and Co from recycled e-waste with fewer steps. Photo Courtesy: Ames Lab

Photo

Caption

Deputy Secretary of Energy, Mark Menezes, and Deputy Assistant Secretary Alex Fitzsimmons cut the ribbon on the expanded Materials Engineering Research Facility at Argonne National Laboratory.

Deputy Secretary of Energy, Mark Menezes, and Deputy Assistant Secretary Alex Fitzsimmons cut the ribbon on the expanded Materials Engineering Research Facility at Argonne National Laboratory.