Investing in energy technologies used in manufacturing has major benefits to our economy and our national security, while also being responsible with a shared environment. It is crucial to ensuring that we can integrate diverse, independent, and reliable sources of energy into the U.S. manufacturing infrastructure. At the same time, the manufacturing of new products related to the efficient and productive use of energy is a tremendous opportunity for economic growth. Over the past decade or more, we’ve seen a surge in the number clean energy products and technologies that are a vital part of the U.S. economy. The revolution in energy efficiency in manufacturing helps companies focus more resources on growing their businesses and staying competitive with other nations, while providing their customers with high-quality products that increase quality of life. So how do we continue to build on this energy revolution and continue to drive American competitiveness in the global clean energy race?

DOE’s recently published "Revolution Now” report highlights emerging technologies that will be crucial to continuing the energy revolution over the decade ahead. These technologies include many Advanced Manufacturing Office (AMO) technology areas like advanced semiconductors, lightweight materials and big area additive manufacturing. These technologies are often the basis for partnerships between other EERE technology offices, combining AMO’s enabling platform technology expertise with their specialized expertise to achieve common goals in advancing clean energy manufacturing.

AMO partners with industry, academia, state and local government, and other stakeholders to identify and support emerging technologies with high potential to advance energy efficiency in the manufacturing of products across the economy as well as enhance the global competitiveness of the U.S. manufacturing sector. This helps ensure high-quality domestic manufacturing jobs as well as the potential for energy independence through technology innovation in manufacturing. AMO’s role is to help drive a revolution in the way new energy technologies are manufactured through projects and partnerships that support applied research, development, and deployment. With breakthrough innovations in the way we manufacture products used in the energy economy, we continue to increase the affordability and accessibility of new energy technologies so that consumers can utilize clean energy without stretching their wallets.

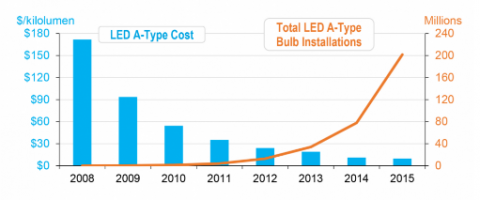

In the last decade, we have seen a great uptake in the adoption of new energy technologies, often corresponding to a significant reduction in their cost through technology innovation. LED lighting, for example, is a clean energy technology that was invented in the U.S. in 1962 by Nick Holonyak, Jr., and it continues to be competitively made here due to technology innovation in both LED products and manufacturing processes. The advancements in manufacturing LED bulbs have resulted in a price reduction of 94% since 2008, making them as economical as traditional incandescent light bulbs. Over that same period of time, LED installations in the U.S. jumped from under 400,000 to over 200 million in 2015. LED bulbs consume up to 85% less energy than their incandescent counterparts and if trends continue, they could save Americans nearly $630 billion in total energy costs between 2015 and 2035.

As technologies like LED lighting become cheaper to install and use, adoption and market penetration skyrocket. (Source: Revolution Now)

AMO works in partnership with the EERE Vehicle Technologies Office to develop lightweight materials such as high strength steel, aluminum, and carbon fiber with the potential to cost effectively reduce the mass of cars, resulting in increased fuel efficiency without compromising vehicle safety. Reduction in the weight of new materials at a potential cost competitiveness with existing materials also offers an opportunity to improve vehicle safety, functionality, and performance of vehicles, while saving energy.

AMO has also partnered with the Wind Energy Technologies Office to apply big area additive manufacturing (BAAM), to the production of wind turbine blade molds. This technology allows for rapid prototyping, reduced waste, and more flexibility in the design of innovative new wind turbine shapes. This work builds on a technology recently used to directly 3D print cars and even a house. Partnerships like this one show the versatility of BAAM technology and demonstrate its value to the clean energy sector.

Advancements in the way we manufacture new energy technologies provide a nexus of benefits to our economy, environment, and national security. American ingenuity will continue to drive the energy revolution forward with high quality products invented in the U.S. and made competitively here.

To read the first blog in this series, click here.