Ten teams receive a collective $1.5 million and Phase 3 opens to returning competitors.

Advanced Materials & Manufacturing Technologies Office

January 14, 2025Latest Announcement

The U.S. Department of Energy’s (DOE’s) Advanced Materials and Manufacturing Technologies Office (AMMTO) today announced the Phase 2 winners of the Re-X Before Recycling Prize, a competition to identify, prepare, and develop innovative ways to extend the lifetimes of products or parts via reusing, repairing, refurbishing, remanufacturing, or repurposing (“Re-X”) before pursuing recycling. From home goods and headlights to furniture and food service items, these creative projects aim to reduce life cycle energy and emissions, strengthen circular supply chains, and decrease the demand for virgin materials.

During Phase 2, competitors leveraged national laboratory expert analysis, refined their plans to further their innovations toward supply chain implementation, and cultivated a network of mentors and partners to optimize the community impact potential of their projects.

“The Phase 2 winners now have the opportunity to put their plans into action to advance our nation’s circular economy,” said AMMTO Director Chris Saldaña. “The impacts of these Re-X projects will strengthen regional manufacturing supply chains, increase U.S. security of supply, create jobs, and reduce environmental burdens.”

Each Phase 2 winner will receive $150,000 in cash and up to $100,000 in technical assistance from a DOE national laboratory. In total, the Re-X Before Recycling Prize has a cash pool of $4.5 million, plus up to $1.1 million in national laboratory analysis consultation and technical assistance.

Learn more about the selected projects.

Phase 3 Opens

The prize’s third and final phase is now open to returning competitors. During this phase, competitors will demonstrate substantial progress towards implementing their innovation in a viable Re-X supply chain, while building ecosystem partnerships through community engagement and developing an actionable plan to continue their project beyond the prize period. Phase 3 submissions are due by 5 p.m ET on Dec. 8, 2025.

Description

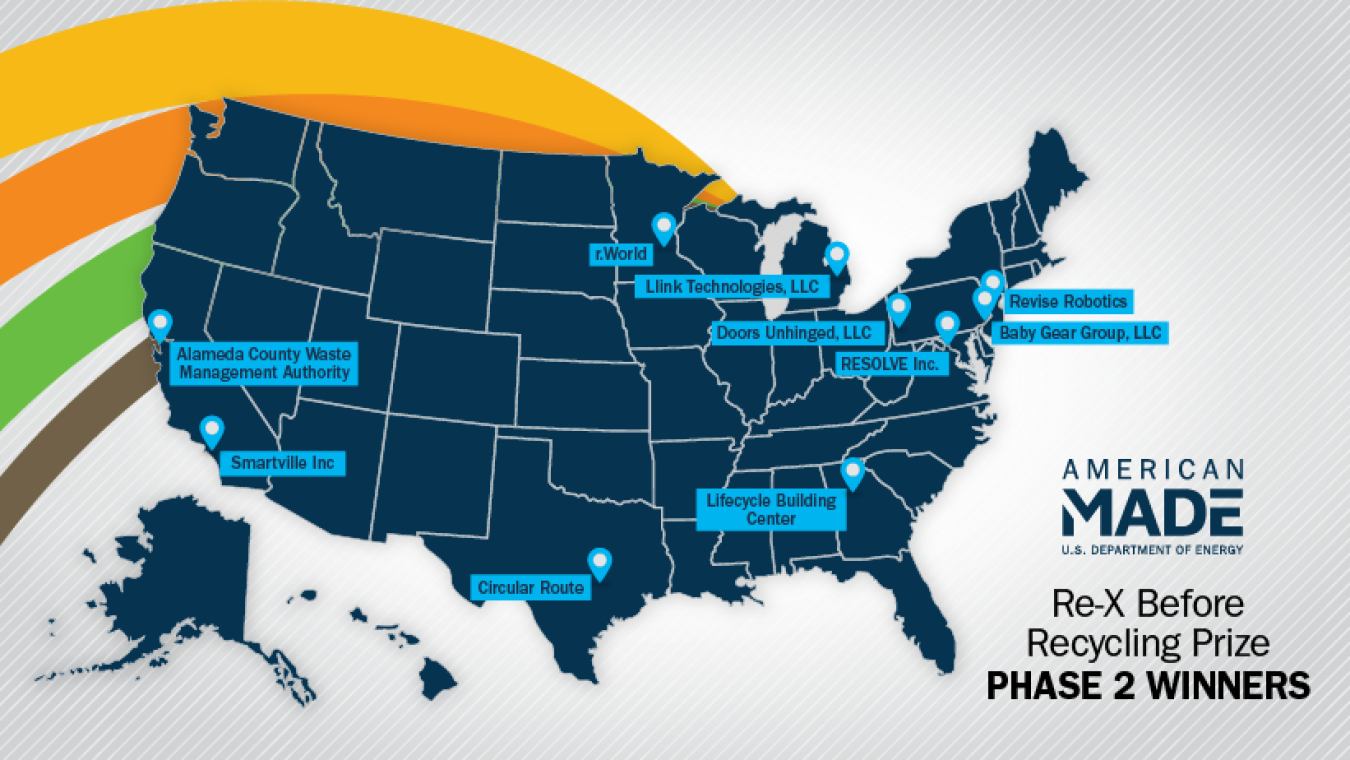

In January 2025, the U.S. Department of Energy (DOE) announced that 10 teams from seven states and Washington, D.C., won Phase 2: Prepare! of the Re-X Before Recycling Prize. Phase 3: Develop! is open to returning participants only.

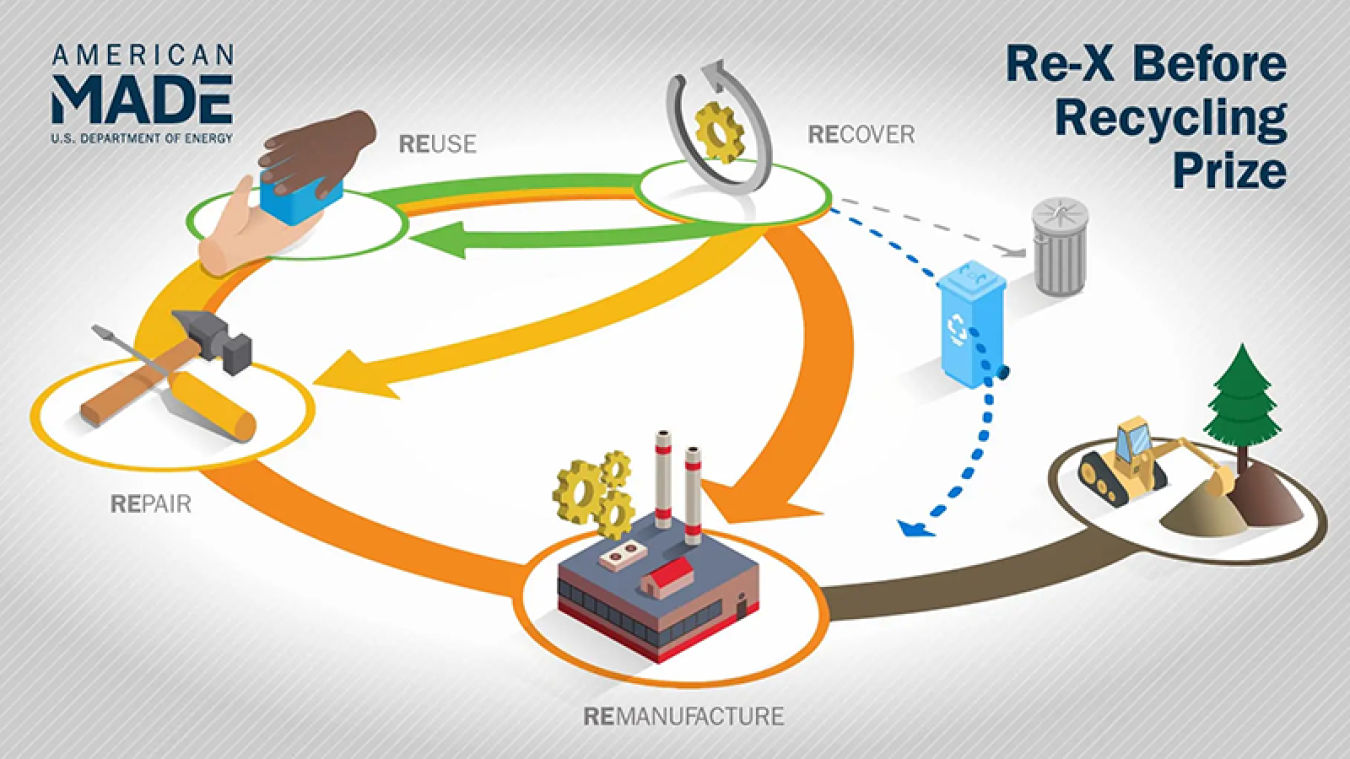

DOE announced the launch of the Re-X Before Recycling Prize on Nov. 27, 2023. This three-phase competition is designed to develop innovative ways to extend the lifetimes of products or parts via reusing, repairing, refurbishing, remanufacturing, or repurposing (“Re-X”) end-of-use products before recycling.

By stimulating novel ideas and private investment in circular economy approaches, the projects developed through this prize will reduce life cycle energy and emissions, strengthen circular supply chains for emerging clean energy technologies, and decrease the demand for virgin materials.

The Re-X Before Recycling Prize is led by DOE’s Office of Energy Efficiency and Renewable Energy’s Advanced Materials and Manufacturing Technologies Office (AMMTO) and managed by the National Renewable Energy Laboratory. Visit the Re-X Before Recycling Prize page on the American-Made program website for more information.

Innovations that enable new or expanded Re-X supply chains can also engage communities and labor.

Follow the Re-X Before Recycling Prize on the official competition platform to learn more about ongoing competitor activities. Visit the Re-X Before Recycling Prize page on the American-Made program website for more information. Find out more about prizes and competitions from DOE’s Office of Energy Efficiency and Renewable Energy.

Phase 2 Winners

During Phase 2, competitors leveraged national laboratory expert analysis, refined their plans to further their innovations toward supply chain implementation, and cultivated a network of mentors and partners to optimize the community impact potential of their projects.

Each Phase 2 winner will receive $150,000 in cash and up to $100,000 in technical assistance from a DOE national laboratory.

Number of Phase 2 Winners: 10

Number of States Containing Selected Projects: 7 and Washington D.C.

Federal Funding Amount: $1,500,000 in cash and $1,000,000 in technical assistance from a national laboratory

Location: Philadelphia, Pennsylvania

Description: Baby Gear Group is a national network of baby gear rental libraries, each maximizing the reuse of baby gear for their local community. The goals of this network include diverting up to 24% of U.S. baby gear waste, reducing emissions by 40% or more, and promoting economic equity by saving families $1 billion annually.

Location: Austin, Texas

Description: ThriftBig is a platform powered by artificial intelligence (AI) that modernizes and optimizes the existing thrift ecosystem by rerouting valuable, durable home goods and furniture from the landfill to refurbishers, repairers, and upcyclers who can reincorporate them back into the economy. ThriftBig has already saved nearly 50,000 pounds of viable used home goods from the landfill in the Austin, Texas, area. In addition, the platform can now be used by charity and thrift stores around the country to move their recoverable items to organizations that can reintroduce them back into the economy.

Phase 1 Winner (as Circular Hub: From Landfill to Livelihood)

Location: Pittsburgh, Pennsylvania

Description: The Doors Unhinged team is pioneering commercial building material reuse by developing a process to refurbish and remanufacture doors that would otherwise be discarded in commercial renovation projects. This reuse process, which leaves doors’ core materials intact while matching the exteriors to new customer specifications, will expand the potential market for refurbished doors.

Phase 1 Winner (as Closing the Door Loop)

Location: Atlanta, Georgia

Description: The Lifecycle Building Center team has designed a way to repurpose the more than 3 million board feet of 2"-by-4" lumber discarded annually by Georgia’s film industry. In addition to its environmental benefits, the process could yield significant social impacts (e.g., for use in affordable housing and workforce development), open new supply chains, and result in a widely scalable/replicable process.

Phase 1 Winner (as ReUse-NLT)

Location: Brown City, Michigan

Description: The Llink Technologies team’s program reuses 95% of components from damaged headlights to remanufacture new headlights backed by the original equipment manufacturer warranty. The resulting headlights provide the same fit, form, and function as brand new headlights, at 60% of the cost and a fraction of the carbon footprint.

Phase 1 Winner (as Remanufactured Headlights: Illuminating the Path)

Location: Minneapolis, Minnesota

Description: r.World is working to keep disposable foodware items out of the trash at large-scale facilities and events by providing a service that enables reuse of these items. Its new AI-powered, automated system reduces the time needed to inspect cups during the r.World wash cycle, lowering operational costs and allowing for more cost-competitive pricing.

Location: Washington, D.C.

Description: Numerous companies are emerging to provide reusable packaging systems for consumer-packaged goods, take-away food and beverages, and transport packaging across cities, campuses, and other public venues. RESOLVE INC.’s PR3 program aligns these existing systems to create interoperability between companies and accelerate efficiencies, convenience, cost savings, job growth, and behavior change.

Phase 1 Winner (as Building the Reuse Infrastructure Grid)

Location: East Windsor, New Jersey

Description: Revise Robotics is building an electronics waste (e-waste) recycling facility where end-to-end robotics and automation will disassemble, process, refurbish, and resell e-waste devices such as laptops, desktops, and peripherals to recover critical materials and keep more e-waste out of landfills.

Location: Oakland, California

Description: Alameda County Waste Management Authority’s project is tracking three reusable foodware models piloted in a local school district, then partnering with a national lab to quantify the economic and jobs impacts of each model. They are creating a toolkit for school districts nationwide that includes the results of the study, encouraging districts to make the switch to reusable foodware and connecting them with the resources to do so.

Location: Carlsbad, California

Description: Smartville’s Periscope is a cost-effective handheld device that quickly collects critical battery health data in the field and then feeds it into a database to identify that battery’s potential for a second life. This unique tool, which works across battery models and can be used by frontline operators, plays a key role in Smartville’s comprehensive ecosystem enabling electric vehicle (EV) battery reuse, repair, refurbishment, and repurposing .

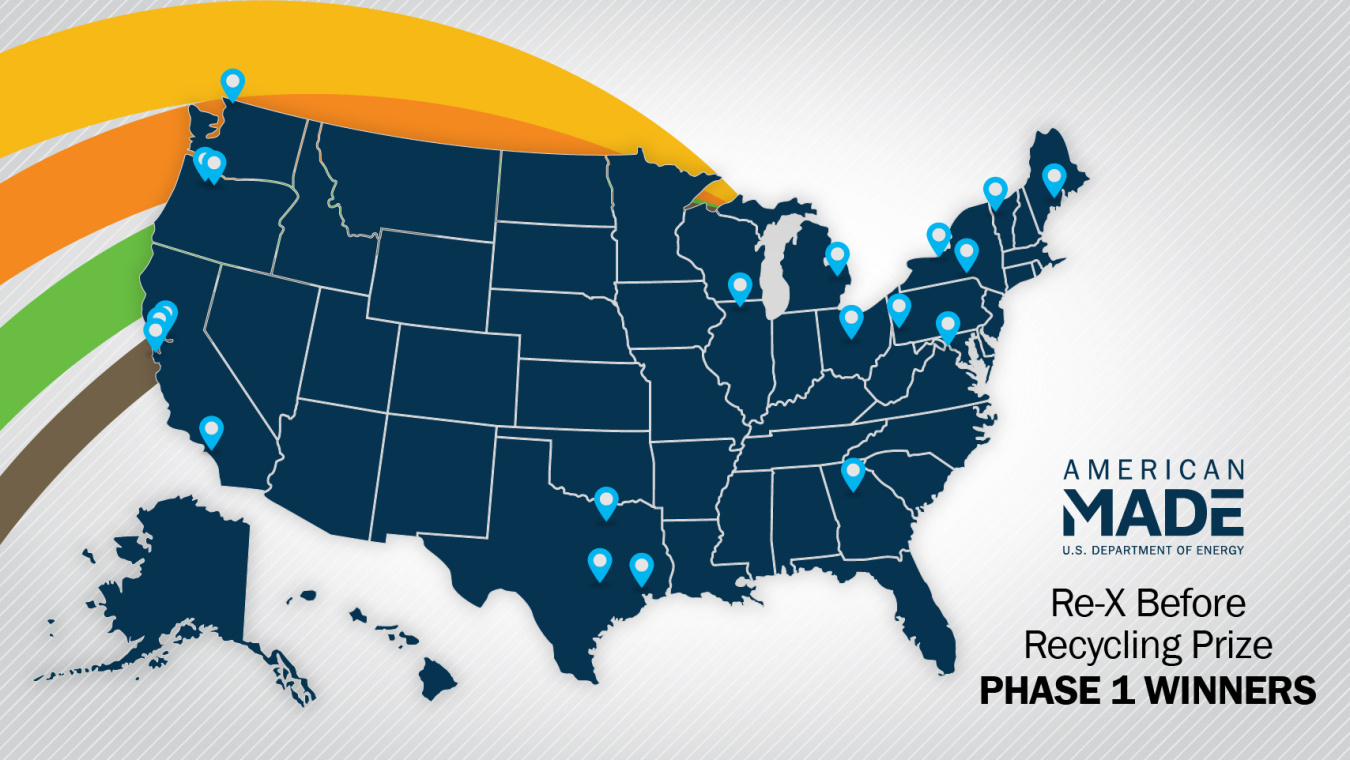

Phase 1 Winners

During the first phase of the competition, applicants were challenged to identify an innovation that, if implemented into a new or expanded Re-X supply chain, would deliver substantial environmental and community benefits. Applicants also developed a plan to advance the innovation from its current state towards implementation in a viable Re-X supply chain.

Each Phase 1 winner received $50,000 in cash and up to $5,000 worth of consultation from a national laboratory, intended to help the teams further refine their concepts during Phase 2 of the competition.

Number of Phase 1 Winners: 20

Number of States Containing Selected Projects: 12 and Washington, D.C.

Federal Funding Amount: $1,000,000

Location: Columbus, Ohio

Description: The Bleckmann U.S. LLC team is developing a holistic closed-loop supply chain resource for apparel and textile companies, enabling circularity by offering collection, repair, refurbishment, and resale. The team has identified each intervention point to address the moment waste is created and redirect it so that it is used at its highest value and is ready to scale their solution through piloting with a variety of brands.

Location: Sacramento, California

Description: The California Product Stewardship Council will establish a ‘Solar Panel Reuse Hub’ in partnerships with cities/counties and solar leaders to increase resources on safe solar panel reuse. The objective of the hub is to identify facilities that repair or refurbish panels, develop an education campaign, form partnerships to organize diversion of working panels, and review current end-of-life management processes.

Location: Austin, Texas

Description: The Circular Route team developed a concept for a Circular Hub System that collects unwanted durable home goods—from charities, junk haulers, moving companies, etc.—and shares them with a network of small businesses interested in refurbishing those items. The purpose of this hub is to extend the life of major contributors to landfills, like furniture, mattresses, appliances, rugs, and more.

Location: Pittsburgh, Pennsylvania

Description: The Doors Unhinged, LLC team is pioneering commercial building material reuse. They have developed a process to remanufacture doors—usually discarded in commercial renovation projects—so that the core material is left intact, but the exterior can match new customer specifications, expanding the potential market for refurbished doors.

Location: Bellingham, Washington

Description: Electra is developing a product registry to provide traceable lifecycle management, collection, and logistics for solar panels. Solar panel owners will register their product on installation, enabling the Virtual Product Stewardship Organization to efficiently track and direct panels to optimal end-of-life outcomes (e.g., reuse, refurbishment, or recycling).

Location: Binghamton, New York

Description: The Liberated ICs project team is developing a patent-pending technology to disassemble electronics, refurbish the valuable integrated circuits (the “ICs” part of their project name), and sell them to U.S. manufacturers for use in new electronics. The system utilizes an advanced convolutional neural network and supervised learning techniques to identify, remove, and test components.

Location: Atlanta, Georgia

Description: The Lifecycle Building Center team will use salvageable dimensional lumber from Georgia’s film industry to mass produce nail-laminated timber (the “NLT” part of their project name) panels for reuse in affordable housing projects. NLT panel production requires modest capital or facility investment, offers local employment opportunities, lowers the cost of building affordable housing, and diverts material from landfills.

Location: Brown City, Michigan

Description: The Llink Technologies, LLC team’s program reuses 95% of components from damaged headlights to remanufacture new, warrantied headlights. Even after a collision, the semiconductor materials, chips, circuitry, wiring, bulbs, and precious metals found in automobile headlamps are often reusable.

Location: Hayward, California

Description: The Posh Electric LLC team focuses on utilizing end-of-life electric vehicle (EV) batteries for long-duration energy storage. They will manufacture containerized, modular storage systems suitable for demand management and power backup applications by repurposing lithium iron phosphate batteries.

Location: South Burlington, Vermont

Description: The RecycleBalls team is focused on ensuring tennis balls get multiple lives by creating a national recovery community and ecosystem. They ensure that these resource-intensive balls have a life beyond the first tennis match by collecting, sorting based on condition, and routing for direct reuse on courts or in classrooms, remanufacturing via repressurizing, or repurposing.

Location: Signal Hill, California

Description: The ReJoule Incorporated team has developed a method using electrochemical impedance spectroscopy to assess an electric vehicle (EV) battery’s state of health directly via the charging port, eliminating the need to remove it from the vehicle. The team’s innovation helps to unlock circular supply chains by reducing risks for buyers of used EVs and routing EV batteries for appropriate second-life uses.

Location: Humble, Texas

Description: The Renewable Parts team has developed a business model by which wind turbine parts can be refurbished and resold, leading to lower lead times, lower carbon footprints, and lower costs for wind energy developers. The new Texas facility will manage reverse logistics, refurbishment, and distribution of finished components.

Location: Fairfield, California

Description: The RePurpose Energy, Inc team’s innovation utilizes machine learning to test, sort, and repurpose EV batteries to commercial and utility energy storage systems. They are developing technology to rapidly assess the battery state of health to determine if it should be repurposed for energy storage or recycled.

Location: Washington, D.C.

Description: The RESOLVE INC team will be pilot testing the PR3 Reusable Packaging Standards, which enable the movement of reusable packaging in circular systems, proper environmental accounting, and secure financial interoperability throughout the supply chain. This will ensure reusable packaging can be collected, washed, redistributed, and reused in place of packaging that is thrown away. The standards will also ensure that these systems are accessible to low-income and underserved communities.

Location: Rochester, New York

Description: The Gen7 team from the Rochester Institute of Technology has developed a workspace-as-a-service model that remanufactures office furniture to minimize the flow of material to municipal waste streams and save companies money. They are working to establish a hub-and-spoke network starting with Seneca Holdings and scaling that network to Tribal nations across the United States.

Location: Rockford, Illinois

Description: The Rockwind Venture Partners team is working to refurbish decommissioned wind turbines and reuse them in distributed energy applications. The team’s innovation will help establish the recycling and reuse of entire wind turbines in the United States.

Location: Portland, Oregon

Description: The Sankofa Lumber team is establishing an ecosystem to unlock direct reuse of construction wood waste on their Timber and Wood Recovery Campus in Oregon. The innovation hub that is created will bring together multiple small businesses in a central location to share resources, create business opportunities, and foster workforce development.

Location: Hillsboro, Oregon

Description: The Shorepower Technologies Inc. team is focused on making electric vehicle (EV) charging more affordable in disadvantaged communities. They are developing a transportable, direct current fast charging system for EVs using repurposed EV batteries in a modular transportable container. This technology will require less grid power than traditional direct current fast charging, thus avoiding the need for utility upgrades.

Location: Fort Worth, Texas

Description: Instead of surplus business materials ending up in landfills, The Welman Project team works to reroute surplus business materials to classrooms in Fort Worth, Texas. This innovative model uses community engagement and partnerships to ensure teachers have the supplies they need to provide curriculum-enhancing experiences for free. To ensure the economic viability of this supply chain economically viable, the team operates a creative reuse craft store to sell the materials classrooms don't need.

Location: Damariscotta, Maine

Description: The Upstream Policy Institute, Inc. team is working to catalyze the adoption of reusable food and beverage containers through innovative funding models. The project will reduce the amount of waste associated with food service items and packaging by developing forward-facing, high-volume contracts to promote the build-out of public infrastructure needed to scale reuse systems.

Key Dates

| Phase 1 Submission Opens | Nov. 27, 2023 |

| Phase 1 Submission Closes | March 12, 2024 |

| Phase 2 Submission Opens | April 11, 2024 |

| Phase 1 Selections Announced | June 17, 2024 |

| Phase 2 Submission Closes | Oct. 22, 2024 |

| Phase 2 Selections Announced | Jan. 14, 2025 |

| Phase 3 Submission Opens | Jan. 14, 2025 |

| Phase 3 Submission Closes | Dec. 8, 2025 |

| Phase 3 Selections Announced | Early 2026 |

More Information

- View the American-Made Challenges website for this prize.

- View the full rules document for this prize.

- Sign up for the Office of Energy Efficiency and Renewable Energy (EERE) email list to get notified of new EERE funding opportunities. Also sign up for AMMTO’s Manufacturing Moment newsletter to stay current with the latest news from our office.