General Motors has attained the U.S. Department of Energy’s 50001 Ready status at twenty five of its U.S.-based plants.

July 16, 2020By Alex Fitzsimmons, Deputy Assistant Secretary for Energy Efficiency, U.S. Department of Energy

DOE’s 50001 Ready program provides a self-paced process for organizations to build energy awareness and increase the energy efficiency of their facilities. The program makes the energy savings associated with the principles of the International Organization for Standardization (ISO) 50001 accessible to organizations without formal certification and through no-cost guidance, tools, and protocols. DOE’s 50001 Ready program is managed by the Office of Energy Efficiency and Renewable Energy’s Advanced Manufacturing Office (AMO). The 50001 Ready program supports AMO’s goal to improve the energy efficiency and competitiveness of American manufacturing.

As of June 2020, 60 sites have achieved 50001 Ready recognition status, representing a wide range of manufacturing and industrial facilities, correctional facilities, schools, power plants, commercial office buildings, and more. These 50001 Ready sites are now systematically managing the equivalent energy consumption of nearly three million typical American households.

After achieving 50001 Ready status, sites can re-attest in subsequent years to determine which improvements lead to the greatest and most sustained savings. Sites may also choose to pursue formal certification paths, such as ISO 50001 certification and the Superior Energy Performance 50001™ (SEP 50001™) certification, to achieve further recognition from DOE and the greater public.

Companies that are interested in how 50001 Ready might work for their facilities should explore the 50001 Ready Navigator, an online tool that provides step-by-step guidance for implementing and maintaining an energy management system in conformance with the ISO 50001 Energy Management System Standard. To date, more than 1,000 facilities have started implementing energy management systems using the 50001 Ready Navigator tool.

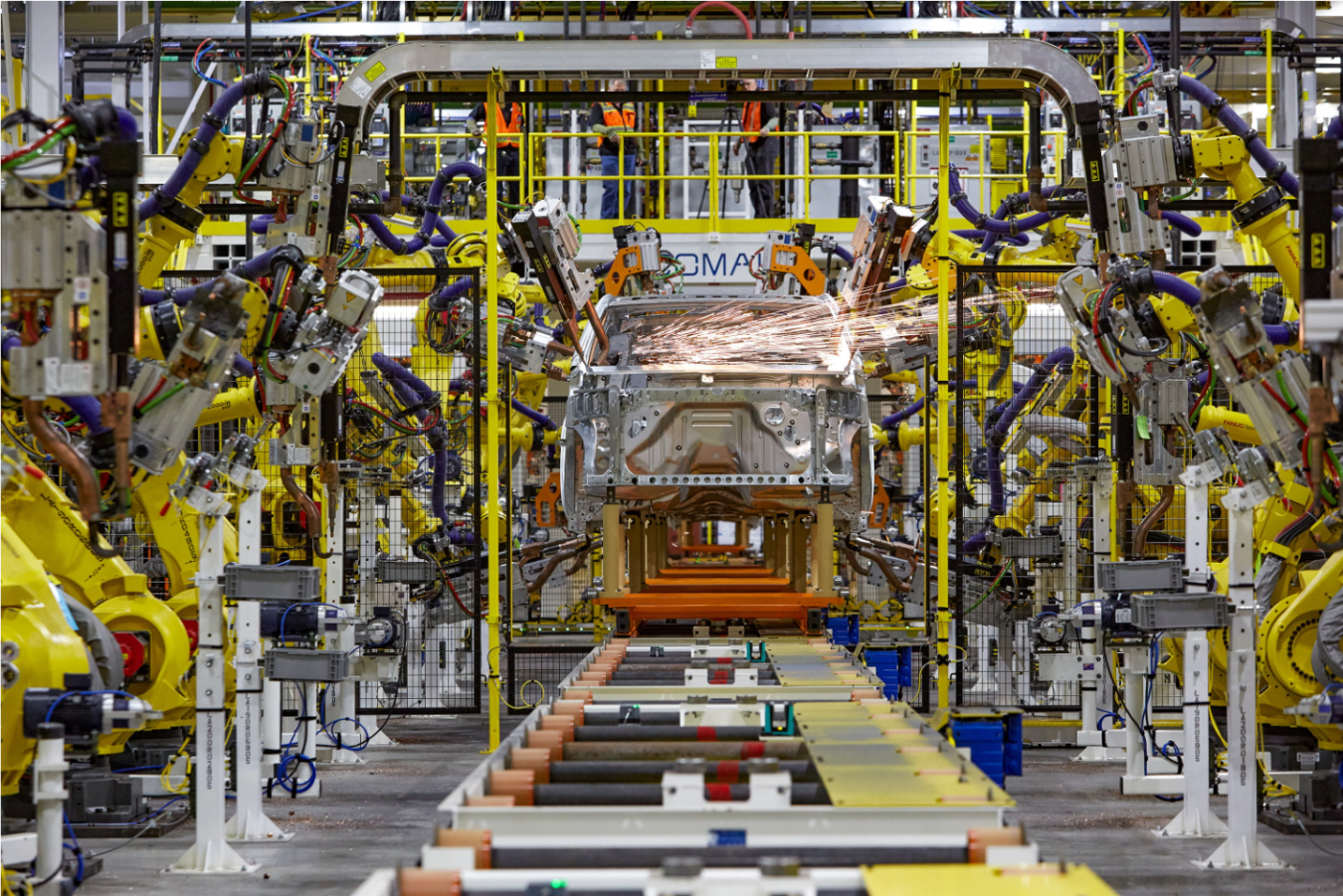

More than 1,400 robots are part of the new 1-million-square-foot body shop at GM’s Arlington Assembly plant.

General Motors (GM) has attained the U.S. Department of Energy’s (DOE’s) 50001 Ready status at 25 of its U.S.-based plants, demonstrating the ability of energy management systems to improve the energy efficiency of facilities across the automotive supply chain. In the case of GM, The 50001 Ready program supports GM’s commitment to sustainability. The 25 sites achieving 50001 Ready status are responsible for a wide range of functions, including metal casting and machining; manufacturing key components and engines; and body shops, paint shops, and general-assembly areas that produce finished vehicles.

The 50001 Ready program helped GM manufacturing plants formalize their existing energy management processes. GM offered a two-and-a-half-day, in-plant training session for its energy conservation engineers from all participating plants. This training activity equipped the engineers with uniform templates and tools. Through the program, each site established a process for managing energy efficiently and for identifying existing procedures that should continue regardless of personnel change.

The 50001 Ready program also enabled GM to compare real-world energy data to modeled predictions. These comparisons help the engineers check or update earlier analyses and engage floor operators in discovering new savings opportunities. In one case, discussions with plant workers led the engineers to begin using electric fans instead of compressed air to dry auto parts—a move that is expected to save more than $100,000 annually.

Looking Forward

50001 Ready status lasts for a period of one year. Companies that re-attest use the baseline data from the first year as a benchmark. As GM’s sites move into their second year with 50001 Ready status, GM will be able to further quantify the energy savings of the program. This additional data can provide evidence of the benefits and persistence of savings for other companies throughout the automotive industry and manufacturing industries.