This month marks the 10th anniversary of radioactive operations for the Actinide Removal Process/Modular Caustic Side Solvent Extraction Unit...

April 26, 2018

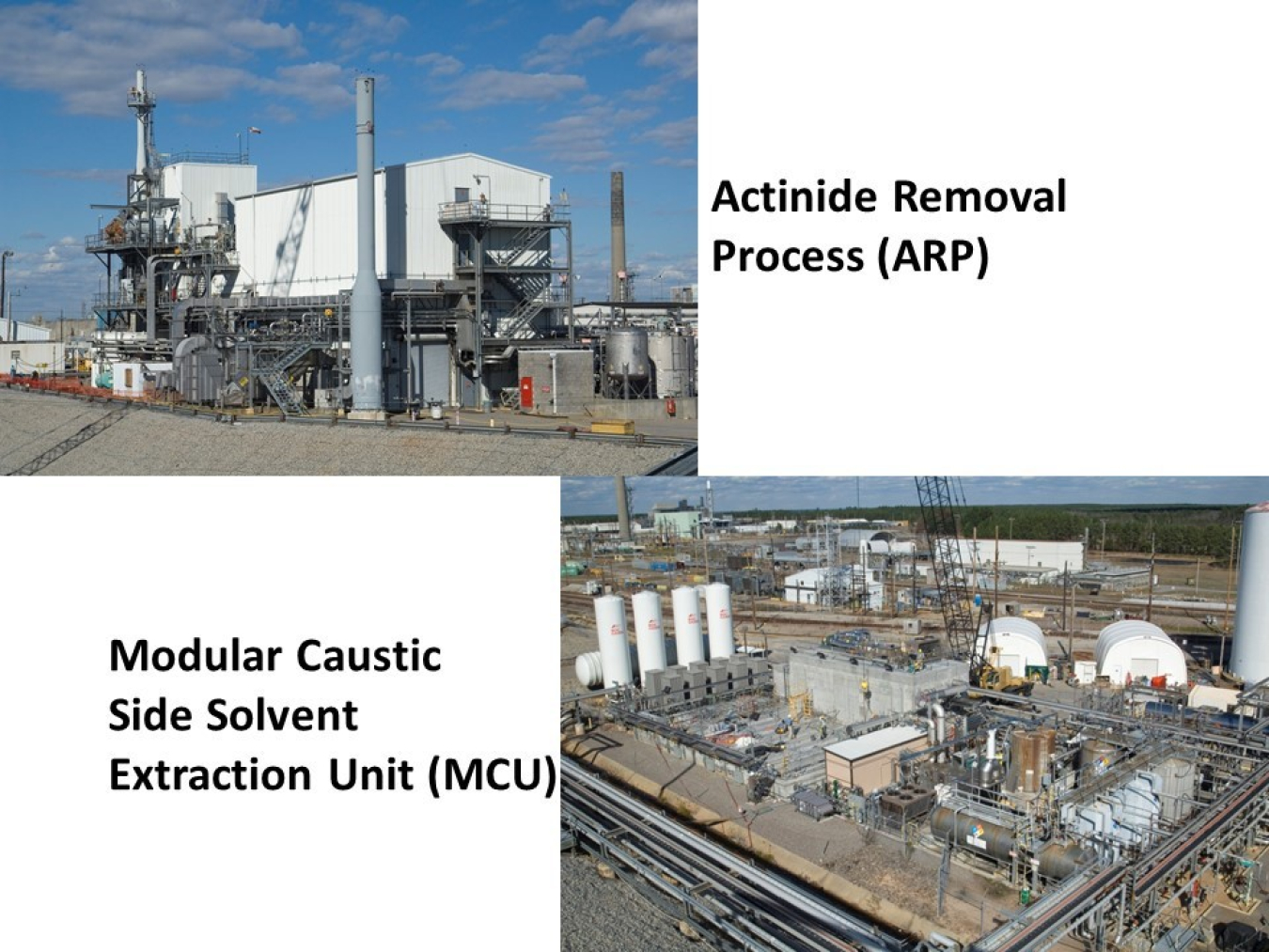

The Actinide Removal Process/Modular Caustic Side Solvent Extraction Unit (ARP/MCU) facilities.

AIKEN, S.C. (April 26, 2018) – This month marks the 10th anniversary of radioactive operations for the Actinide Removal Process/Modular Caustic Side Solvent Extraction Unit (ARP/MCU) facilities, a duo that has played a significant role in six high-level waste tank closures at the Savannah River Site (SRS).

ARP and MCU, coupled as the interim salt waste processing program, are key players in the mission of dispositioning the salt waste in liquid waste operations at SRS. The set of salt-decontamination facilities work as an integrated system to remove nearly all of the radioactive isotopes from the salt waste portion of the radioactive waste in storage tanks.

The radioactive isotopes removed by ARP/MCU are primarily cesium, strontium, and actinides. These isotopes are transferred to the Defense Waste Processing Facility, where they are blended with a borosilicate frit and melted to form a molten glass mixture that is poured into stainless steel canisters. The filled canisters are safely stored at SRS awaiting permanent storage.

The remaining decontaminated salt solution from salt waste processing is transferred to the Saltstone Production Facility (SPF) for disposition in the Saltstone Disposal Units.

Jim Folk, DOE-Savannah River Assistant Manager for Waste Disposition, said the ARP/MCU facilities have proven effective for the past 10 years.

“Processing salt waste is essential for SRS and our mission to close high-level waste tanks,” Folk said.

Nearly 7 million gallons of salt waste have been processed through ARP/MCU since hot operations began in April 2008.

ARP/MCU will continue processing salt waste until the Salt Waste Processing Facility (SWPF) at SRS begins radioactive operations, which will increase current salt processing nearly seven-fold.

SRS has improved the ARP and MCU facilities to prepare for eventual SWPF operations. Liquid waste engineers replaced a solvent used in the ARP/MCU process with one that removes more cesium from the salt waste, providing a lower-curie cesium waste stream to the SPF. Fewer curies means less radioactive material is permanently stored onsite.

Tom Foster, SRR President and Project Manager, praised the work by liquid waste engineers since startup of the interim facilities.

“The engineers and operational staff have done an incredible job spanning 10 years of successful operations and innovations at the ARP/MCU facilities,” Foster said.

Media Contacts:

Sonya Goines, U.S. Department of Energy

803.952.8564

Sonya.Goines@srs.gov

Maddie Blair, Savannah River Remediation

803.208.2634

Madeline.Blair@srs.gov