Many agencies have locations in areas that are moderately or highly corrosive, such as marine environments. When designed, installed and maintained properly, solar photovoltaics (PV) systems can be successfully placed in these challenging locations.

This information is intended to help agencies ensure the success with either existing systems or new proposed solar PV systems.

Corrosion

Corrosion is a common and natural electrochemical process that can affect a wide variety of the materials seen in a solar PV system from polymers (common in solar modules) to metals used in each main component.

Introducing solar system components into a severely corrosive environment can accelerate corrosion processes, leading to severe damage, performance loss, and safety issues. Metal components such as module frames, fasteners, racking systems, inverter electronics, electrical panels, and connectors are particularly vulnerable. Polymers and metal contacts in solar modules are also susceptible to corrosion.

Corrosive Environment

Corrosive environments include sites that are marine adjacent and areas exposed to agricultural dust and gases, air pollution, and other factors which could include some federal sites near industrial areas. A main mechanism of corrosion is galvanic corrosion (discussed in detail below) where dissimilar metals undergo an electrochemical reaction. Solar PV systems often involve a mix of metals, making them prone to this type of corrosion.

The solar industry is just starting to comprehend the unique challenges with solar systems when exposed to challenging environmental and climatic conditions. Codes, standards, and best practices are not yet in place, requiring agency managers to stay informed.

Addressing High Corrosion Risk Areas

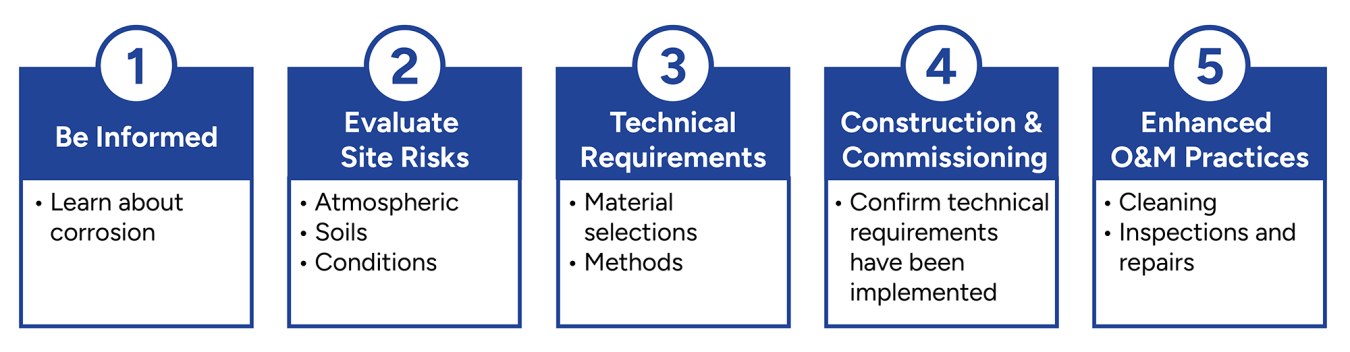

Managing corrosive environments requires an active, systematic approach to identify and then address corrosive agents. Corrosion can be difficult to trace, so thorough investigation and monitoring are essential.

Corrosion planning process.

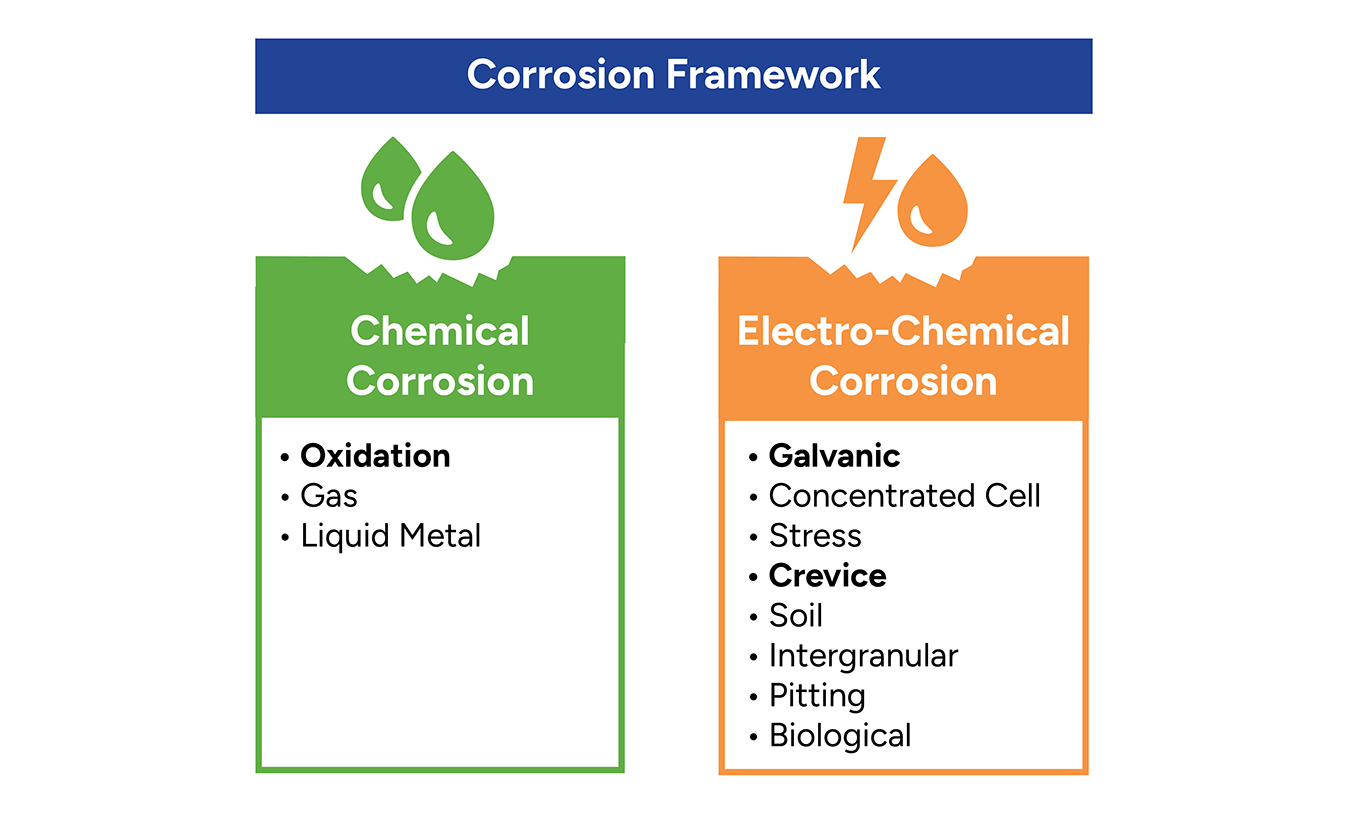

Types of Corrosion

The following three types of corrosion are most commonly seen in solar PV systems. Understanding these types helps agencies better plan for corrosion-resistant design and maintenance strategies.

Oxidation occurs when a metal atom gives up electrons to an oxygen molecule (O2) in the presence of moisture containing minerals (electrolyte). In the case of a steel part, iron oxide (rust) is created, which is not a protective layer, meaning the entire part can corrode until completely gone. When other types of metals go through oxidation, a protective layer is formed and no further corrosion occurs.

Oxidation is commonly seen in rooftop solar PV components like inverter cabinets, combiner boxes, and conduit unions—even in non-marine locations. Heat will speed corrosion reactions on rooftops systems exposed directly to the sun’s heat. If left unaddressed, these examples would result in total failure of the component and affected sections of the solar system.

Pictured: Common examples of oxidation corrosion on solar PV systems. Photo by Gerald Robinson, LBNL

Fasteners are particularly vulnerable. Inadequate finishes can lead to significant degradation, increasing long-term maintenance costs. The mitigations tables address existing and new proposed systems under design.

Pictured: Oxidation corrosion on fasteners. Photo by Gerald Robinson, LBNL

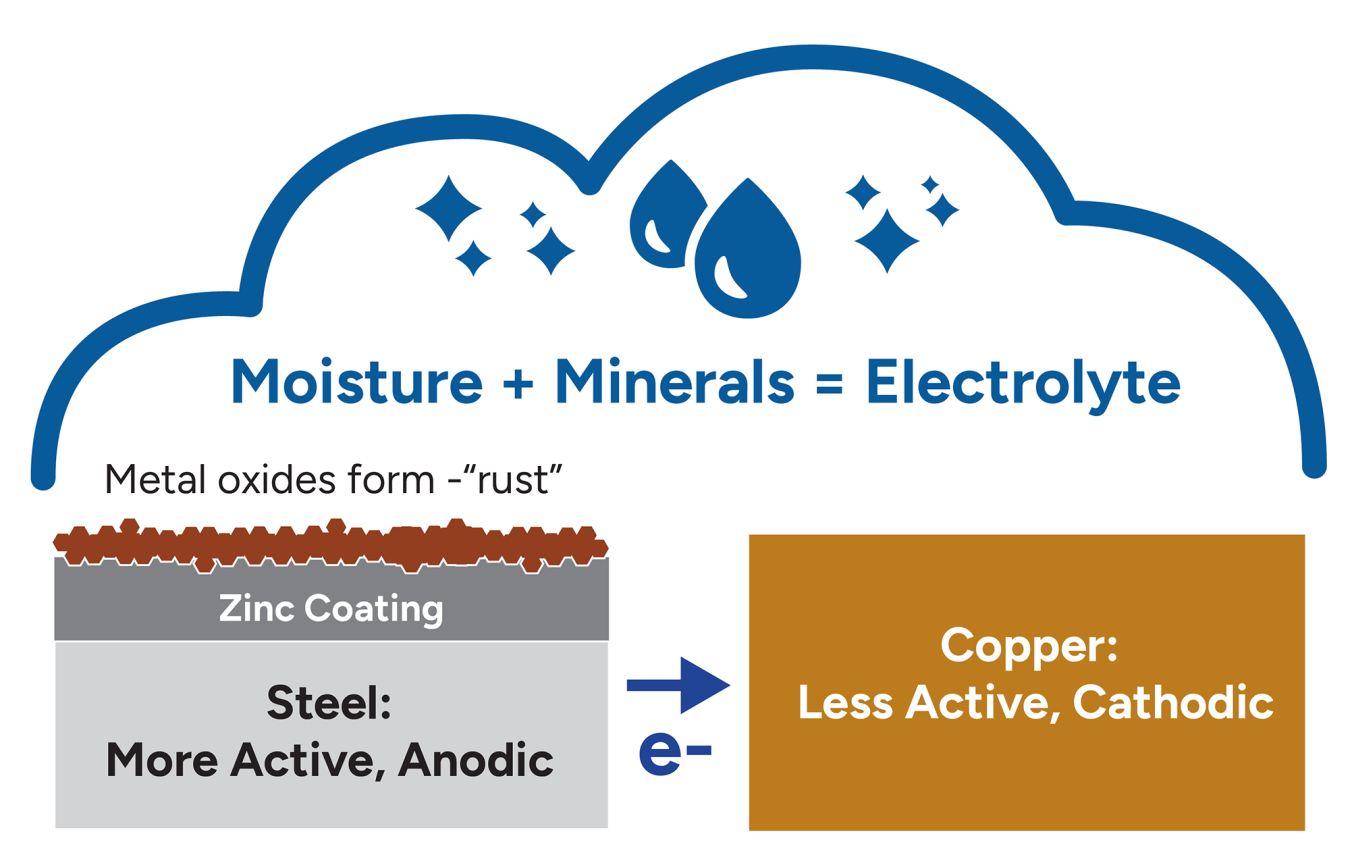

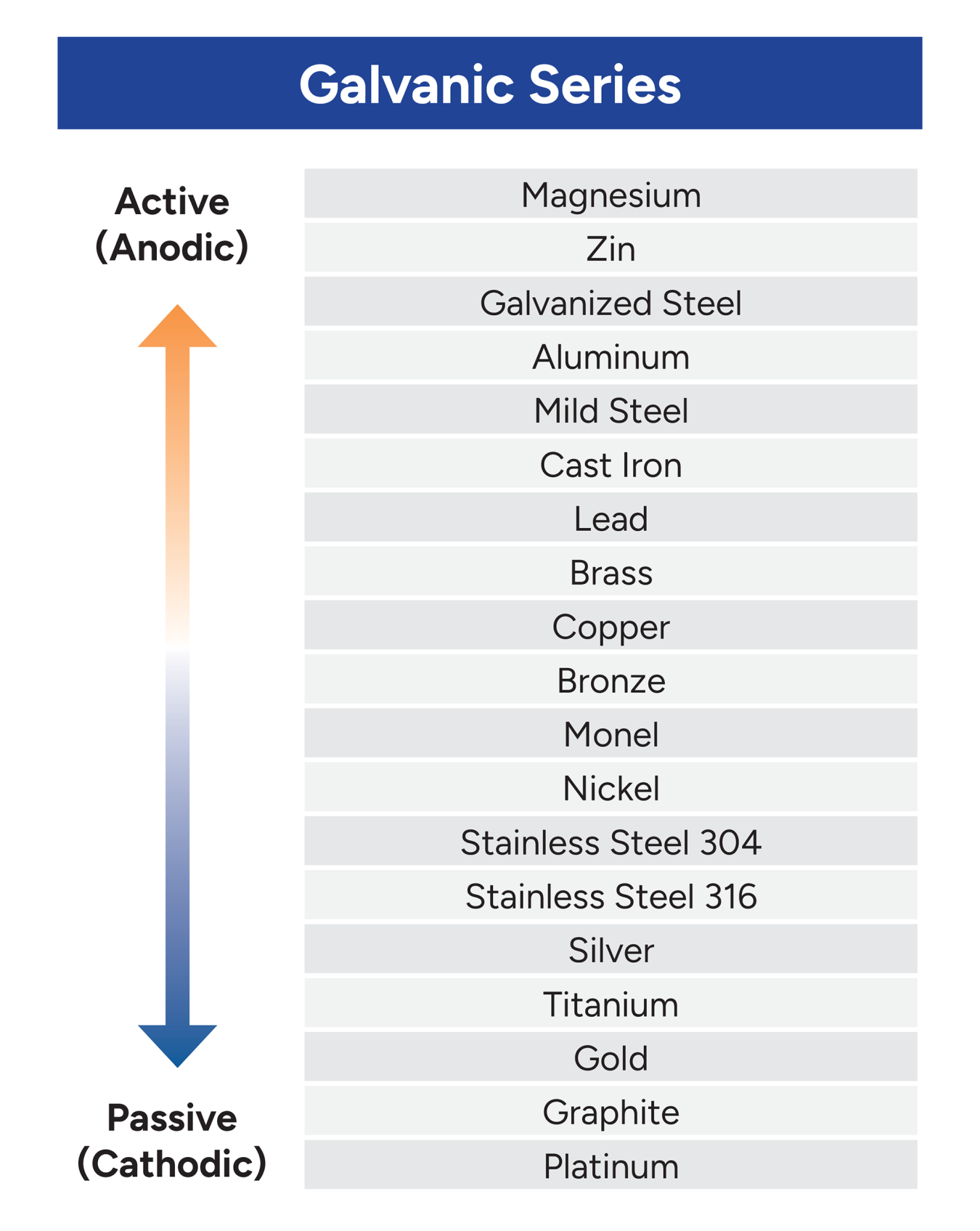

Also called dissimilar metal corrosion, this electrochemical process occurs when two dissimilar metals are in electrical contact in the presence of an electrolyte (moisture and minerals). One metal is the active, or “anodic” metal. This anodic metal corrodes more rapidly than the other (less active, “cathodic”) metal by losing an electron to it.Pictured: Galvanic corrosion.

The Galvanic Series table ranks metals by reactivity. The further away two metals are on the scale, the higher the risk of corrosion between them.Solar PV systems often pair stainless steel fasteners with aluminum frames mounted to steel or aluminum purlins. Improper grounding or fastener selection can degrade the safety and reliability of bonding systems, which must comply with UL 2703 standards and support 25 years of fault-current protection.

Pictured: Galvanic series table.

Pictured: A standard-grade steel fastener was used to attach a brass grounding lug to a galvanized purlin. The fastener degraded and likely reduced the ability of the bonding system to carry fault currents. Photo by Gerald Robinson, LBNL

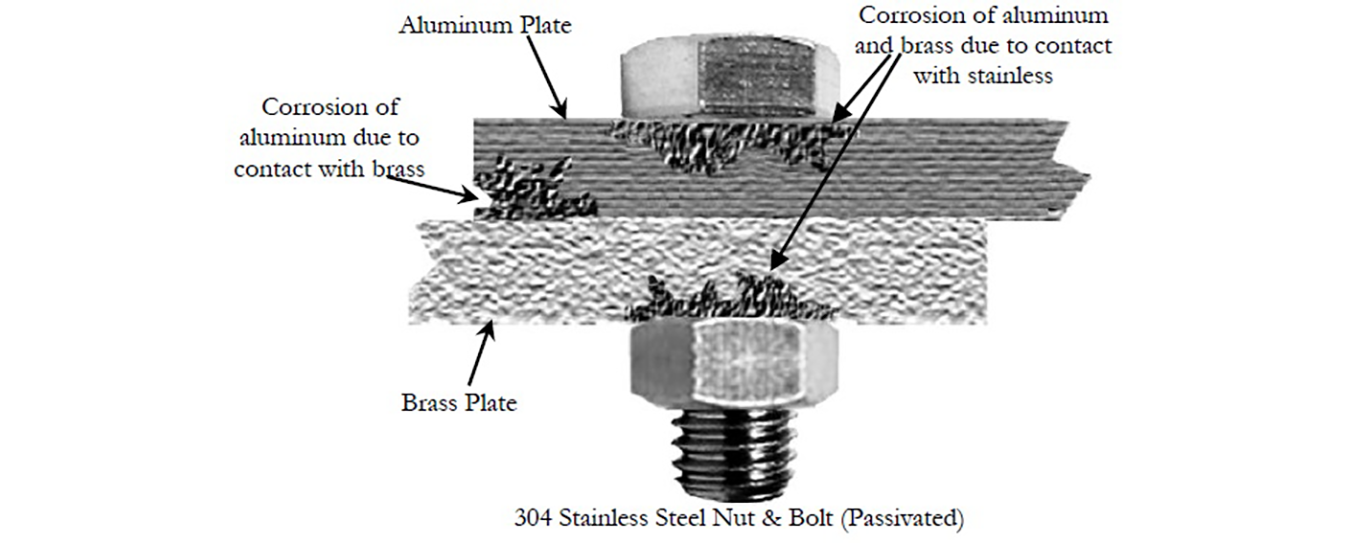

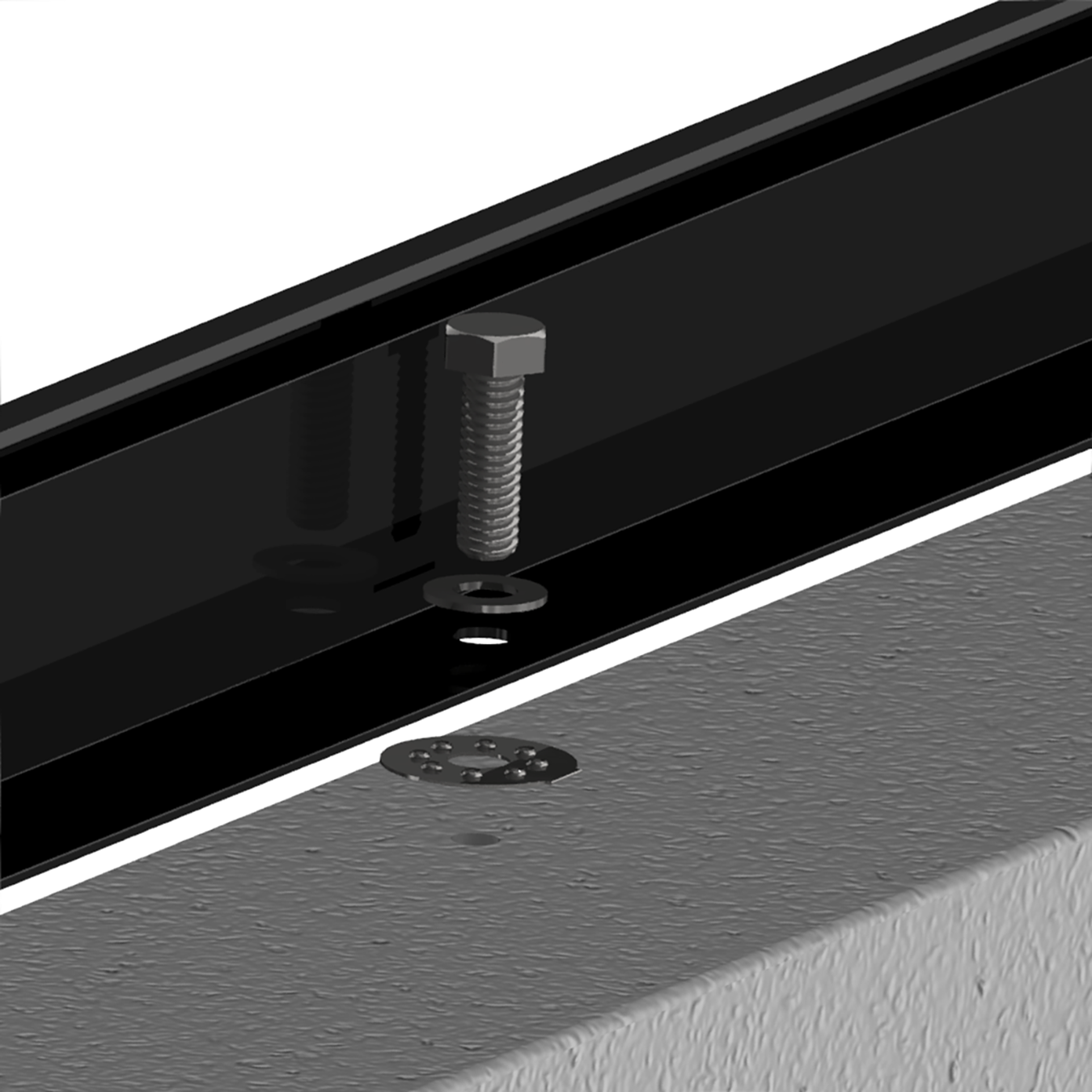

Pictured: A module fastener was used with an added stainless-steel bonding device to pierce the aluminum anodizing to then allow for a conductive pathway for fault current. This is a critical safety connection point that must be kept free of galvanic corrosion impacts. Corrosion will likely increase electrical resistance through the joint presenting potential safety concerns. Photo from HubbellCrevice corrosion occurs at the microscopic contact surfaces between two metals. When two materials are in contact, surface irregularities result in gaps along the contact surface and create pockets where an electrolyte is trapped causing corrosion.

Crevice corrosion. Image from Fastenal.com

Aluminum-framed modules often use stainless steel fasteners and bonding plates to create electrical pathways. These points can suffer from crevice corrosion, which both weakens the mechanical joint and interrupts bonding.

Types of corrosion common in solar PV systems include oxidation, galvanic, and crevice.

Potentially Induced Degradation Solar Modules

Marine environments with high humidity and the presence of salts (chlorides) can present other challenges such as potentially induced degradation in modules, however this is not covered in this factsheet other than one recommendation for module selection criteria based on standard test methods (see section on recommendations).

Site Assessment Best Practices

Corrosion assessments differ from geotechnical studies. A full corrosion study should cover the topical areas shown in the table below.

Checklist - Contents of a Good Site Corrosion Study

| AGENT/FACTOR | AGENT DETECTED? | MEASURING SEVERITY | |

|---|---|---|---|

1. Site knowledge | Known corrosion activity | ||

| Pictures of corrosion | |||

| Locations/patterns of corrosion | |||

| Reports done by others | |||

2. Atmospheric | Salt-marine | ||

| Wind blown salt air patterns for site | |||

| Humidity | |||

| Recurring dew events | |||

| Temperatures (expected in array) | |||

| pH from any sources above | |||

3. Local airborne | Dust from corrosive soil | ||

| Industrial dust | |||

| Pollutants | |||

| Agricultural dust | |||

| Ammonia (NH3) | |||

| pH from any sources above | |||

4. Soil | Chlorides, sulfur | ||

| Pollutants (e.g nitrates) | |||

| Moisture profile - site drainage | |||

| Resistivity | |||

| pH of soil |

Atmospheric Corrosion Assessments

Several tools can estimate corrosion risk based on site location but should not be solely relied upon. Site-specific factors, like wind patterns and localized industrial emissions, require on-the-ground evaluation.

Mitigation Measures

Download the spreadsheet for detailed mitigation strategies to reduce corrosion in solar PV systems.

Operations and Maintenance

Good operations and maintenance is an important and effective way to reduce the impact of corrosion—especially from atmospheric sources like salt mist. Review the operations and maintenance table for detailed guidance.

Operations and Maintenance Measures - Good Practices in Corrosive Environments

| COMPONENT | MITIGATION MEASURE | APPLICABILITY | BENEFIT |

|---|---|---|---|

| Recurring electrical preventive maintenance | Follow NFPA 70B to ensure critical electrical equipment is inspected, cleaned, tightened, and tested on a recurring schedule necessary to prevent damage from corrosion. | All balance of system components on the DC and AC side would greatly benefit from regular maintenance. | Catch and stop galvanic corrosion before serious damage occurs. |

| Spray treatments are non-conductive and provide corrosion protection to electrical components. | Can be used on lugs and other electrical connectors to prevent corrosion. | Prevents galvanic corrosion from starting. | |

| Galvanized fasteners corroded | Apply zinc metallizing spray coatings. | Corroded galvanized fasteners. | Zinc is a sacrificial metal and will protect the fastener metal and strength. |

| Plant growth | Keep plants cut back to allow air to flow freely. | Generally applicable to the whole system. | Reduces humidity in the air and soil, which can slow galvanic corrosion reactions. |

| Leafy debris around roof systems | Remove leafy debris in and around roof arrays. Clear roof drains. | Common to solar PV systems on low sloped roofs where leafy debris can build up around racking and rooftop equipment. | Allows air to flow and keep humidity down, and keep metal dry and prevent any biologically based corrosion. |

| Array cleaning | Clean with salt neutralizing soaps that are listed safe on all kinds of materials. Look for EPA Bio-Preferred products. | Used widely on all components, including modules and rack framing. | Reduces oxidation and galvanic corrosion. Could help with crevice corrosion. |