A key facility supporting the Hanford Site’s tank waste cleanup mission is back in service following a series of repairs, upgrades and training sessions.

Office of Environmental Management

April 29, 2025Steam started venting at the Hanford Site’s 242-A Evaporator boiler annex, left, in March as workers prepared the evaporator facility, right, to resume operations.

RICHLAND, Wash. — A key facility supporting the Hanford Site’s tank waste cleanup mission is back in service following a series of repairs, upgrades and training sessions.

The 242-A Evaporator removes water from radioactive and chemical waste stored in underground tanks, creating more storage space for waste retrieved from older tanks awaiting treatment as Hanford prepares to begin immobilizing the waste in glass for safe disposal.

Site contractor Hanford Tank Waste Operations & Closure (H2C) restarted the facility in March. It’s now running three campaigns over two months.

“Enhancements made to the evaporator ensure it continues to operate safely and efficiently at a higher capacity, which will be needed to support mission acceleration as we move to the next phase in cleanup,” said Ricky Bang, Hanford deputy assistant manager for Tank Waste Operations.

Upgrades to the facility include:

- Temperature monitoring system upgrades to safeguard operations during cold weather

- Fire and process system upgrades

- Seismic improvements to the boiler annex

- Waste transfer line installation totaling 1,300 feet

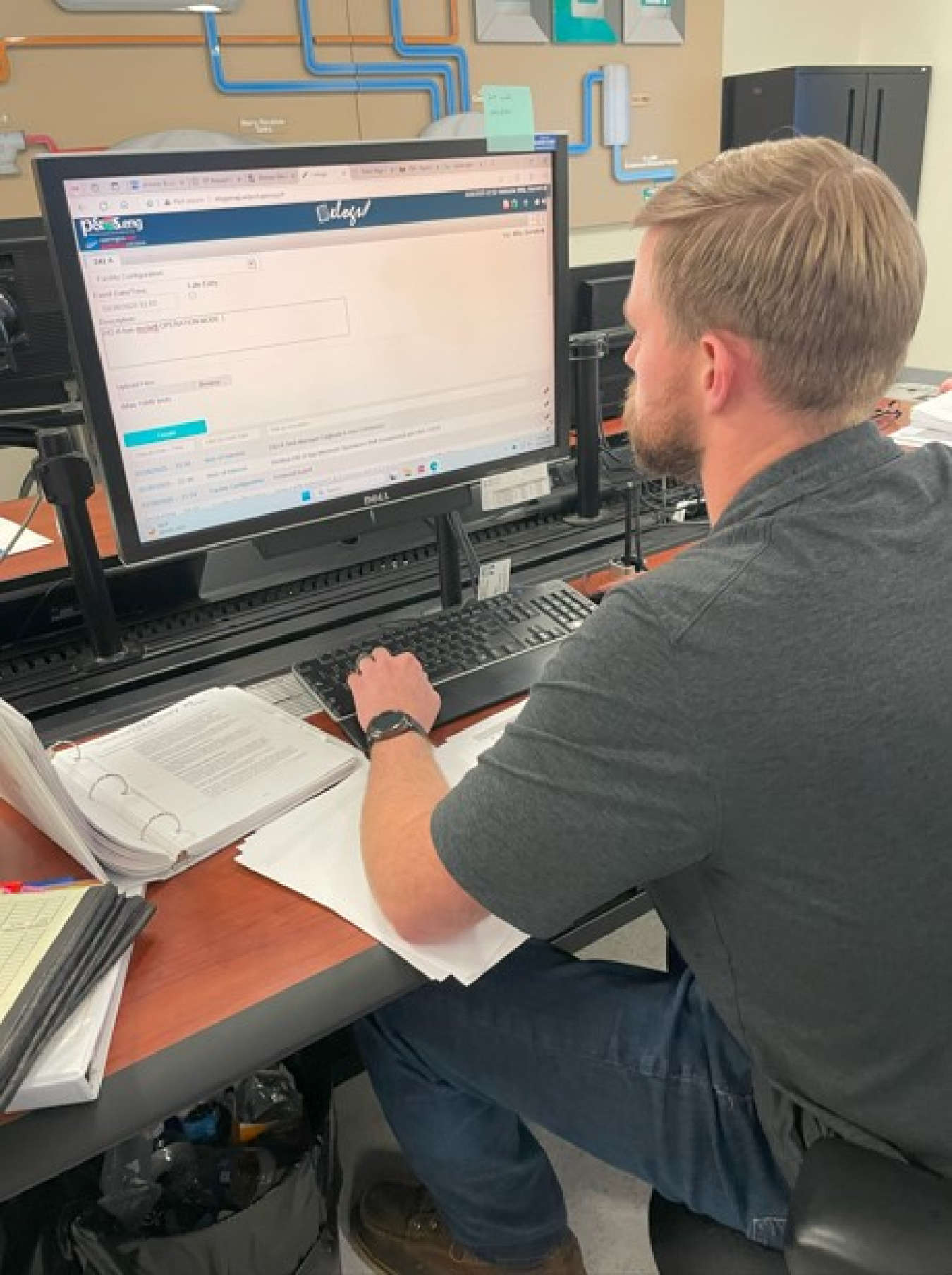

Garrett Wilz, a 242-A Evaporator shift manager for Hanford Tank Waste Operations & Closure, declared the Hanford Site facility in operation mode on March 26, 2025.

Payton Smelser and Ashley Vertner, nuclear chemical operators with Hanford Tank Waste Operations & Closure, perform valving to bring steam to the reboiler as part of the 242-A Evaporator startup.

“This has been a long and difficult but rewarding journey. The facility is safer, the crews are better trained, and processes have improved since the facility last ran in 2019,” said Carol Johnson, H2C president and program manager. “The team’s commitment to the mission is commendable, especially over the last few months.”

The facility receives waste from a nearby group of underground waste storage tanks, where it’s boiled at low pressure to evaporate water. The remaining concentrated waste, known as slurry, is transferred back to a storage tank. The evaporated water is filtered and sent to Hanford’s Effluent Treatment Facility for additional treatment and disposal.

Since the evaporator began operating nearly 50 years ago, it has helped remove more than 81 million gallons of liquid from the site’s waste tanks.

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.